Method of water treatment process

A water treatment and process technology, applied in the field of sewage treatment in the hydrometallurgical zinc smelting process, can solve the problems of high sulfur content in slag, high desulfurization cost, large consumption of filter cloth, etc. Low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

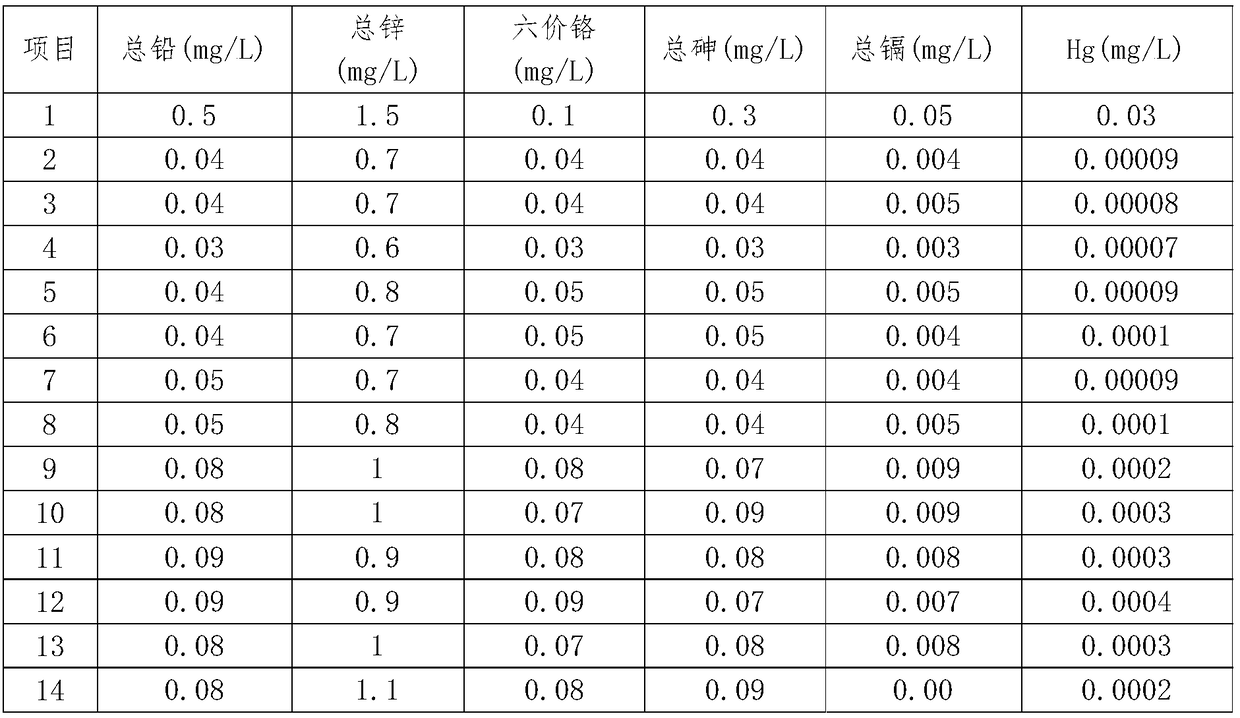

Examples

Embodiment 1

[0024] The present embodiment provides a method for water treatment process, comprising the following steps:

[0025] (1) Add lime milk supernatant to the acidic wastewater containing heavy metals, adjust the pH value to 7.0, until the precipitation stops; then filter and separate the precipitation to obtain the first filtrate with waste residue left at the bottom;

[0026] (2) Add lime milk supernatant again in the first filtrate, adjust the pH value to be 8.5, to stop producing precipitation; Then add Na in the filtrate 2 S, Na 2 The weight ratio of the amount of S added to the heavy metal in the first waste liquid is 1.3:1, until the precipitation stops again; then filter and separate the precipitate in the first filtrate to obtain the second filtrate with waste residue left at the bottom; The second filtrate is subjected to biochemical treatment to obtain purified water.

Embodiment 2

[0028] The present embodiment provides a method for water treatment process, comprising the following steps:

[0029] (1) Add lime milk supernatant to acid waste water containing heavy metals, adjust the pH value to 8.0, until the precipitation stops; then filter and separate the precipitation to obtain the first filtrate with waste residue left at the bottom;

[0030] (2) Add lime milk supernatant again in the first filtrate, adjust the pH value to be 8.5, to stop producing precipitation; Then add Na in the filtrate 2 S, Na 2 The weight ratio of the amount of S added to the heavy metal in the first waste liquid is 1.3:1, until the precipitation stops again; then filter and separate the precipitate in the first filtrate to obtain the second filtrate with waste residue left at the bottom; The second filtrate is subjected to biochemical treatment to obtain purified water.

Embodiment 3

[0032] The present embodiment provides a method for water treatment process, comprising the following steps:

[0033] (1) Add lime milk supernatant to acid waste water containing heavy metals, adjust the pH value to 7.5, until the precipitation stops; then filter and separate the precipitation to obtain the first filtrate with waste residue left at the bottom;

[0034] (2) Add lime milk supernatant again in the first filtrate, adjust the pH value to be 8.5, to stop producing precipitation; Then add Na in the filtrate 2 S, Na 2 The weight ratio of the amount of S added to the heavy metal in the first waste liquid is 1.3:1, until the precipitation stops again; then filter and separate the precipitate in the first filtrate to obtain the second filtrate with waste residue left at the bottom; The second filtrate is subjected to biochemical treatment to obtain purified water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com