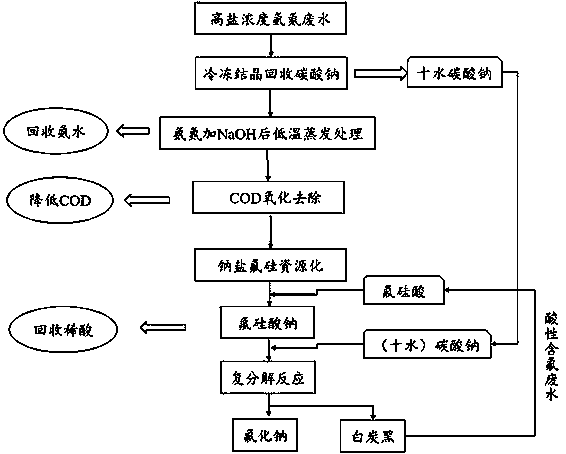

Method for recycling fluorosilicone in high-salt ammonia-nitrogen wastewater and producing sodium fluoride with coproduction of white carbon black

A technology of ammonia nitrogen wastewater and sodium fluoride, which is applied in the directions of ammonia compounds, alkali metal fluorides, silicon oxides, etc., can solve the problems of complex process, high treatment cost, unrecycled salts, etc., so as to improve economic benefits and reduce treatment costs. cost, the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: A method for producing sodium fluoride using high-salt ammonia-nitrogen waste water, fluorine and silicon as resources:

[0031] The high-salt ammonia nitrogen wastewater in this example includes the following components in mass percentage: 1) 20% ammonium chloride; 2) 25% sodium chloride.

[0032] Utilize high-salt ammonia nitrogen waste water to produce sodium fluoride co-production white carbon black in the present embodiment and comprise the following steps:

[0033] (1) Ammonia nitrogen treatment: Take 1 kg of the above wastewater, add 150g of sodium hydroxide to the wastewater (that is, the mass ratio of sodium chloride to high-salt ammonia nitrogen wastewater is 1:6.67), and enter the ammonia recovery system. Ammonia water is recovered after evaporation; in this step, the ammonium chloride component in the high-salt ammonia nitrogen wastewater reacts with sodium hydroxide to generate 128 g of ammonia water and 214 g of by-product sodium chloride, and t...

Embodiment 2

[0041] Example 2: A method for producing sodium fluoride using high-salt ammonia nitrogen waste water, fluorine and silicon resources:

[0042] The high-salt ammonia nitrogen wastewater in this example includes the following components in mass percentage: 1) 4% ammonium chloride; 2) 5% sodium chloride.

[0043] Utilize high-salt ammonia nitrogen waste water to produce sodium fluoride co-production white carbon black in the present embodiment and comprise the following steps:

[0044] (1) Ammonia nitrogen treatment: Take 1 kg of the above wastewater, add 30 g of sodium hydroxide to the wastewater (that is, the mass ratio of sodium chloride to high-salt ammonia nitrogen wastewater is 1:33.3), enter the ammonia recovery system, and the ammonia nitrogen in the wastewater is passed through Ammonia water is recovered after low-temperature evaporation; in this step, the ammonium chloride component in the high-salt ammonia-nitrogen wastewater reacts with sodium hydroxide to generate 2...

Embodiment 3

[0052] Example 3: A method for producing sodium fluoride using high-salt ammonia-nitrogen waste water, fluorine and silicon resources:

[0053] The high-salt ammonia nitrogen wastewater in this example includes the following components in mass percentage: 1) 12% ammonium chloride; 2) 15% sodium chloride.

[0054] Utilize high-salt ammonia nitrogen waste water to produce sodium fluoride co-production white carbon black in the present embodiment and comprise the following steps:

[0055] (1) Ammonia nitrogen treatment: Take 1 kg of the above wastewater, add 90 g of sodium hydroxide to the wastewater (that is, the mass ratio of sodium hydroxide to high-salt ammonia nitrogen wastewater is 1:11.1), and enter the ammonia recovery system. Recover ammonia water after low-temperature evaporation; in this step, the ammonium chloride component in the high-salt ammonia-nitrogen wastewater reacts with sodium hydroxide to generate 76.8 g of ammonia water and 128 g of by-product sodium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com