Integrated packaging case and manufacturing method thereof

A production method and packaging box technology, applied in packaging, biological packaging, sustainable packaging industries, etc., can solve the problems of inability to recycle, waste resources, and have a great impact, save resource consumption, reduce environmental protection pressure, and package tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

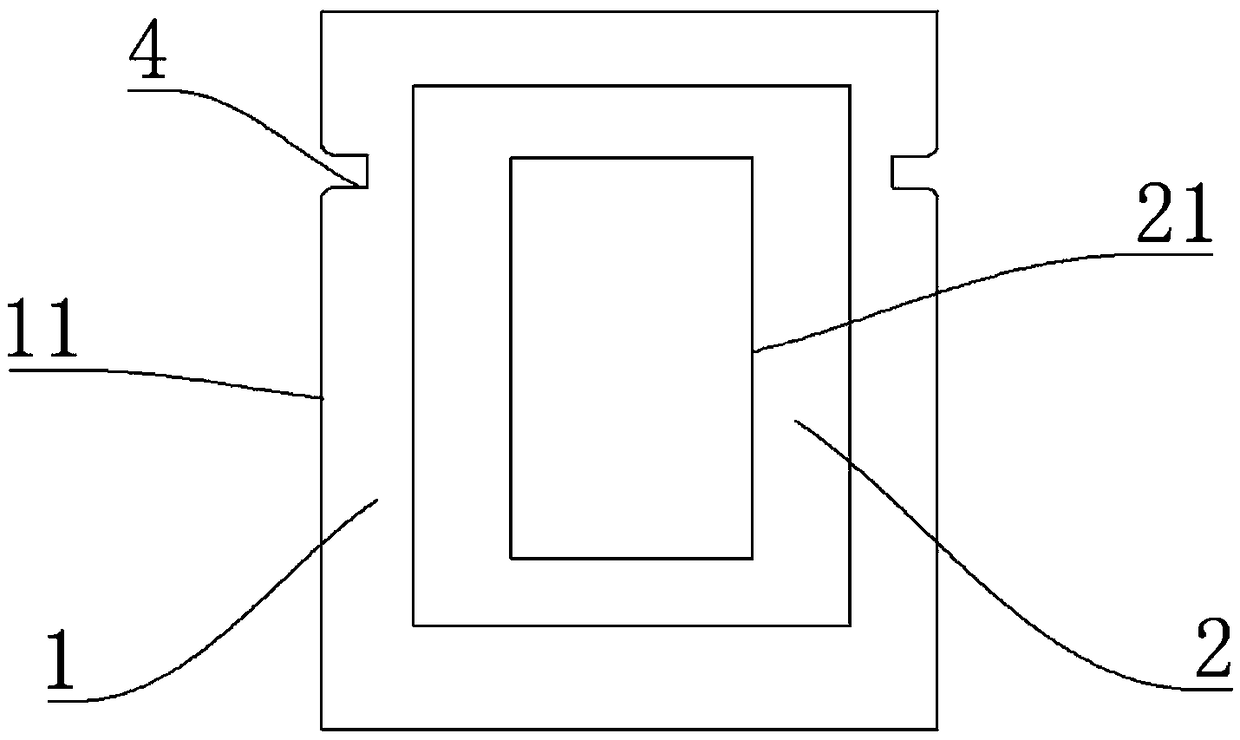

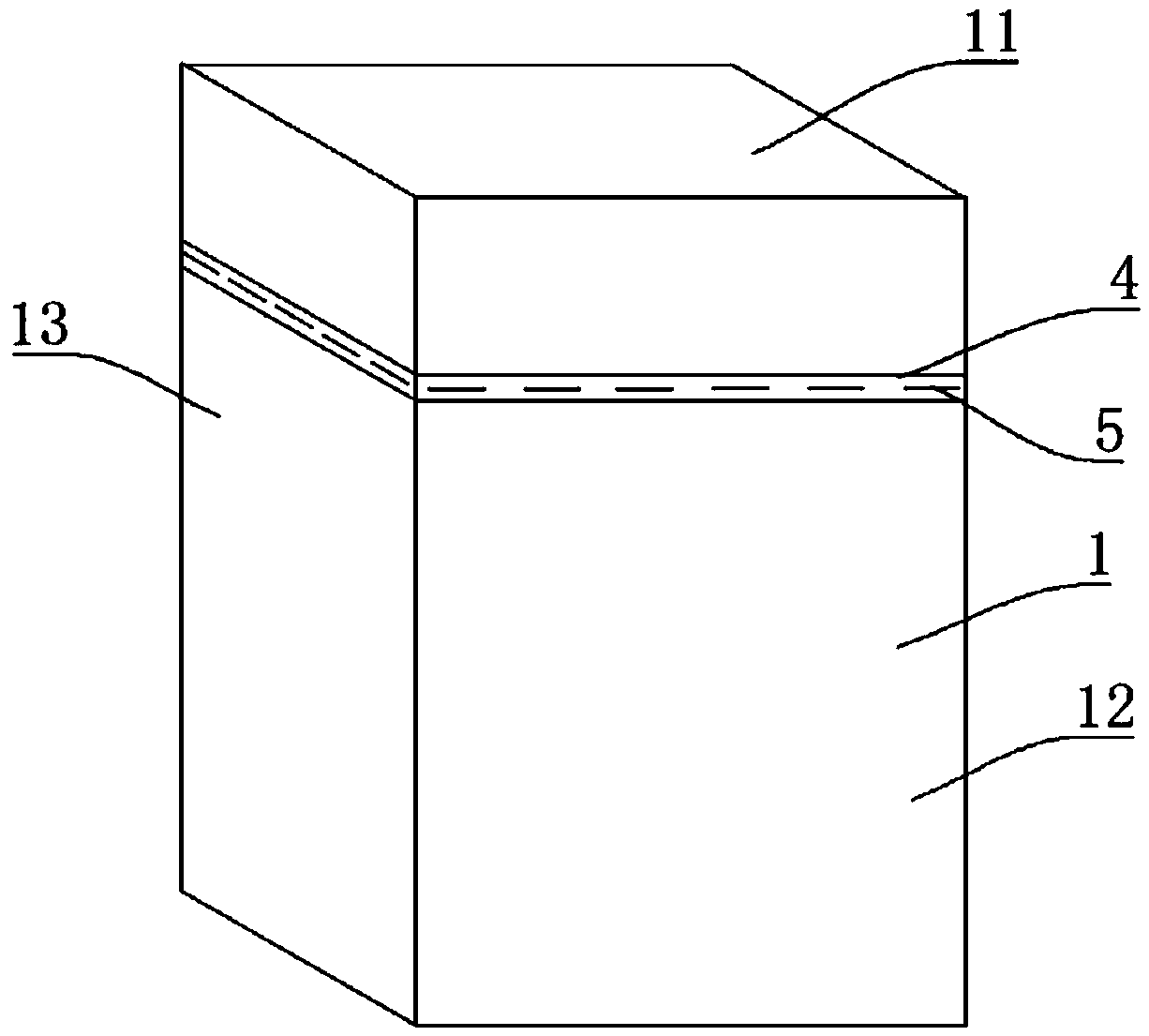

[0024] refer to Figure 1 ~ Figure 2 , the manufacturing method of the integrated packing case of the present invention, comprises the following steps:

[0025] Step a, taking a first mold, and placing the object in the first mold;

[0026] Step b, place the first mold in step a on the injection molding machine, take HL-303 thermoplastic starch plastic and ADC-DN3 foaming agent, and mix HL-303 thermoplastic starch plastic and ADC-DN3 foaming agent in a weight ratio of 500 : 4 Add in the first barrel of BS-SZEB2-24 type disc injection molding machine, stir and heat HL-303 thermoplastic starch plastics and ADC-DN3 foaming agent, and inject the raw materials and foaming agent into the first Wrap the object in a mold, the injection temperature is 200°C, the mold temperature is 70°C, the injection pressure is 45bar, the holding pressure is 35bar, the injection speed is 55g / s, the cooling time is 70s, and the inner shell is obtained. 2;

[0027] Step c, taking the second mold, an...

Embodiment 2

[0031] refer to Figure 1 ~ Figure 2 , the manufacturing method of the integrated packing case of the present invention, comprises the following steps:

[0032] Step a, taking a first mold, and placing the object in the first mold;

[0033] Step b, place the first mold in step a on the injection molding machine, take 801-1X natural straw plastic and ADC-DN3 foaming agent, mix 801-1X natural straw plastic and ADC-DN3 foaming agent in a weight ratio of 700 :4 Add it into the first barrel of ZY-850-SS vertical multi-station injection molding machine, stir and heat 801-1X natural straw plastic and ADC-DN3 foaming agent, and inject the raw materials and foaming agent into In the first mold, wrap the article, the injection temperature is 180°C, the mold temperature is 60°C, the injection pressure is 30bar, the holding pressure is 25bar, the injection speed is 50g / s, and the cooling time is 50s. shell2;

[0034] Step c, taking the second mold, and putting the inner shell 2 into the ...

Embodiment 3

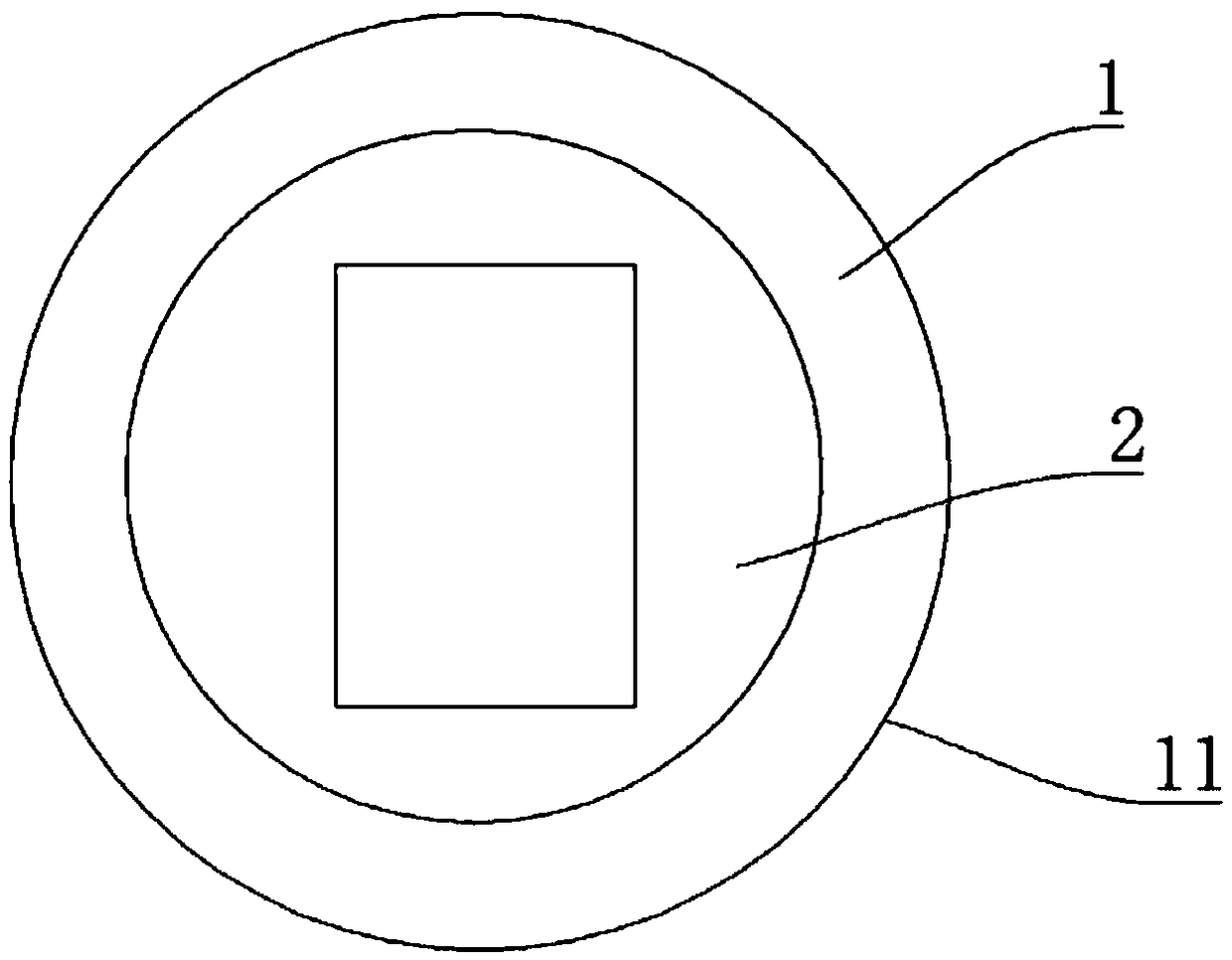

[0038] refer to image 3 , the manufacturing method of the integrated packing case of the present invention, comprises the following steps:

[0039] Step a, taking a first mold, and placing the object in the first mold;

[0040] Step b, place the first mold in step a on the injection molding machine, take HL-303 thermoplastic starch plastic and ADC-DN3 foaming agent, and mix HL-303 thermoplastic starch plastic and ADC-DN3 foaming agent in a weight ratio of 500 : 4 Add in the first cylinder of ZY-850-SS vertical multi-station injection molding machine, stir and heat HL-303 thermoplastic starch plastics and ADC-DN3 foaming agent, and inject the raw materials and foaming agent into In the first mold, wrap the article, the injection temperature is 190°C, the mold temperature is 65°C, the injection pressure is 37.5bar, the holding pressure is 30bar, the injection speed is 52.5g / s, the cooling time is 60s, and demoulding is carried out. Get inner shell 2;

[0041] Step c, taking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com