Gap compensation mechanism and steering gear applying same

A gap compensation and gap adjustment technology, applied in the direction of mechanical steering gear, etc., can solve the problems of increased meshing gap of worm gear, poor driver's control comfort, poor driver and passenger comfort, etc., to reduce noise, avoid Risk of abnormal noise and effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment proposes a backlash compensation mechanism 1 and a steering gear using the backlash compensation mechanism 1, so that the tooth backlash of the worm gear in the steering gear can be kept within a predetermined range, the steering comfort of the steering gear can be improved, and the steering gear can be reduced. noise.

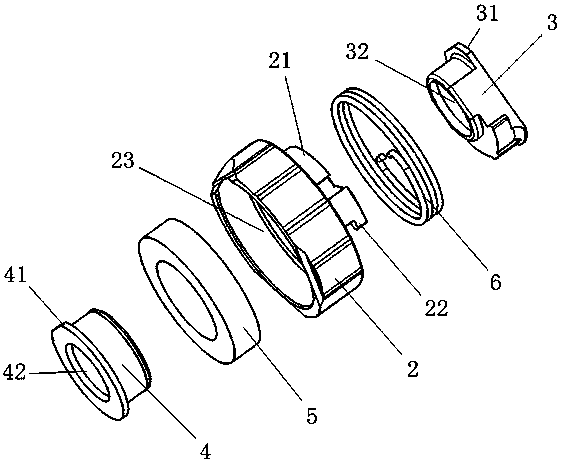

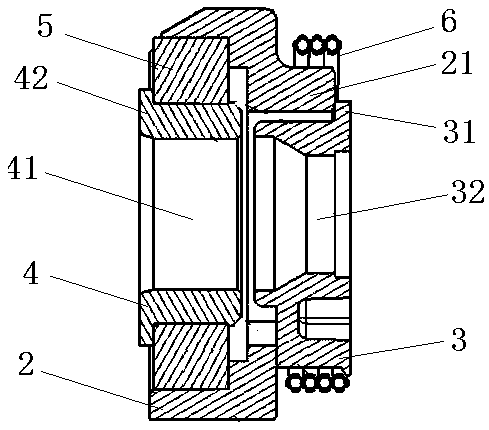

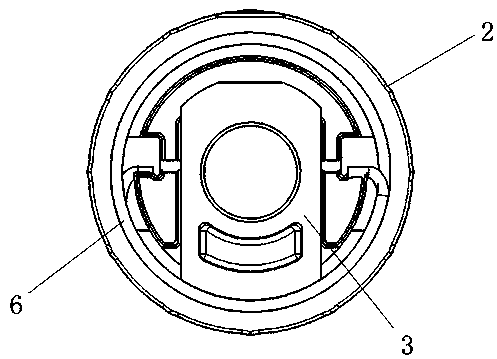

[0029] Such as Figure 1~4 As shown, the gap compensation mechanism 1 of this embodiment is composed of a gap adjustment seat 2, an end support seat 3, a central support seat 4, a gap adjustment bearing 5 and a radial spring 6, wherein:

[0030] The gap adjusting seat 2 is roughly in a cylindrical structure, the middle part of which is provided with a first axial through hole 23, and the outer end of the gap adjusting seat 2 is provided with a protruding arc-shaped wall 21, and the central axis of the arc-shaped wall 21 is aligned with the first axis. coincide with the central axis of the through hole 23; the end support seat 3 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com