Novel multi-link overload servo press

A servo press and multi-link technology, applied in the field of presses, can solve the problems that servo motors are difficult to meet the needs of high power and high torque, reduce the effective output capacity of servo presses, and servo motor synchronous control errors, etc., to achieve Effects that resolve motion and power loss, increase pressure, and improve structural rigidity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

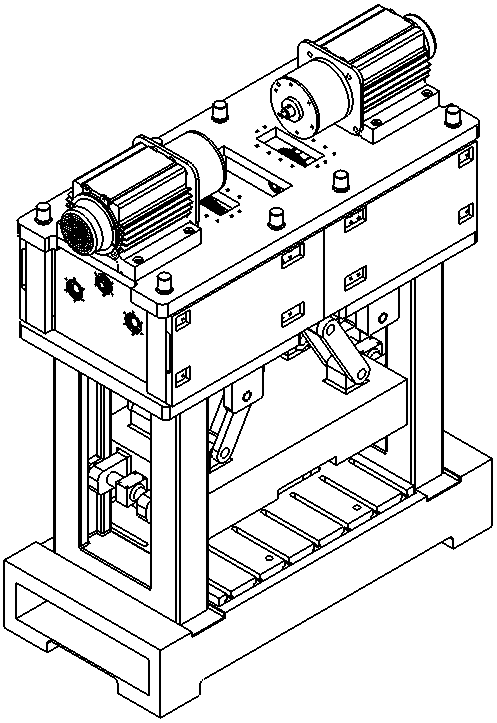

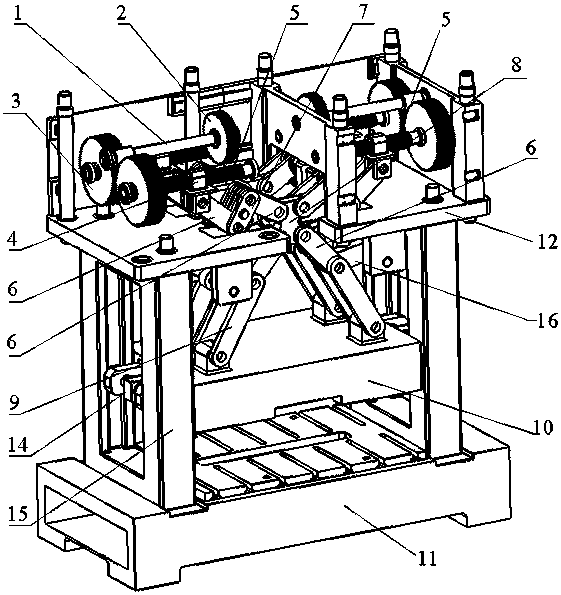

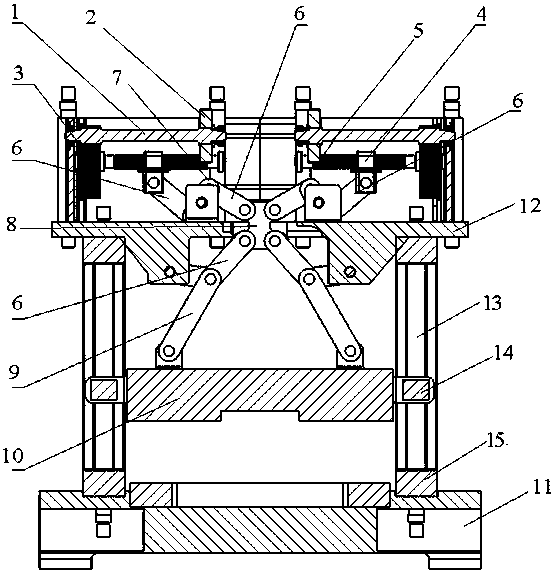

[0042] A novel multi-link heavy-duty servo press is composed of a frame, a slider 10, a power device and two sets of transmission mechanisms.

[0043] The frame is composed of a base 11, a top plate 12 and a pair of supporting cylinders 15; a cavity is arranged inside the cylinder 15, and chute 13 (slide rail) is respectively provided on the inner and opposite sides of the cavity; the slider 10 passes through the The slide bar 14 slides along the chute 13 .

[0044] The main body of the transmission mechanism is a connecting rod 8, the top of the connecting rod 8 is provided with a pair of crank sliders 10 mechanisms which are mirror images of each other, and the bottom end is provided with a pair of toggle mechanisms which are mirror images of each other.

[0045] The crank slider 10 mechanism is composed of the crankshaft 7 whose shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com