Rapid industrial drilling and milling device workpiece fixture

A technology for workpieces and equipment, which is applied in the field of quick fixtures for industrial drilling and milling equipment, can solve the problems of clamp marks on the surface of workpieces, high requirements for fixture installation, and limited use, so as to achieve high clamping efficiency and improve clamping efficiency. fixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

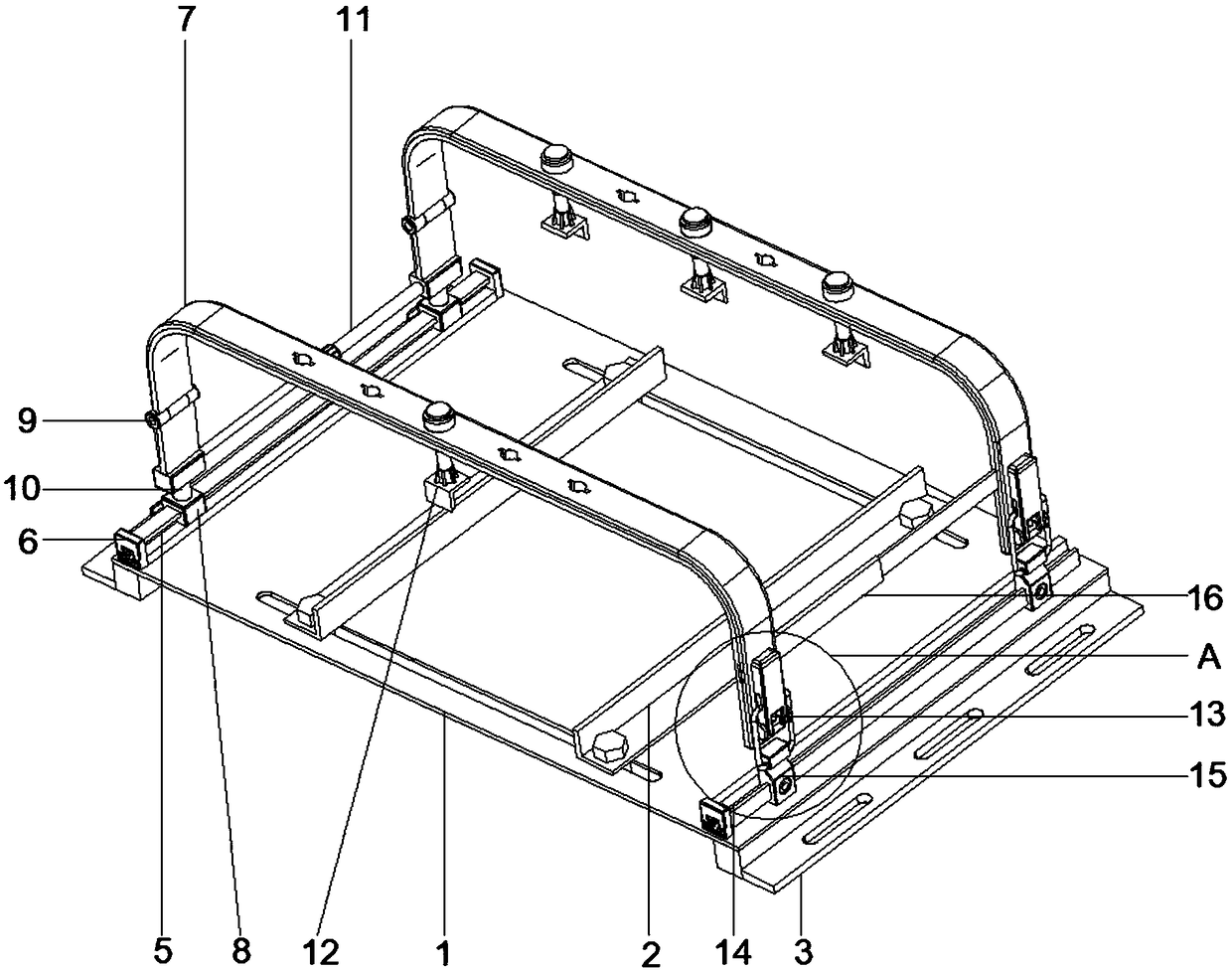

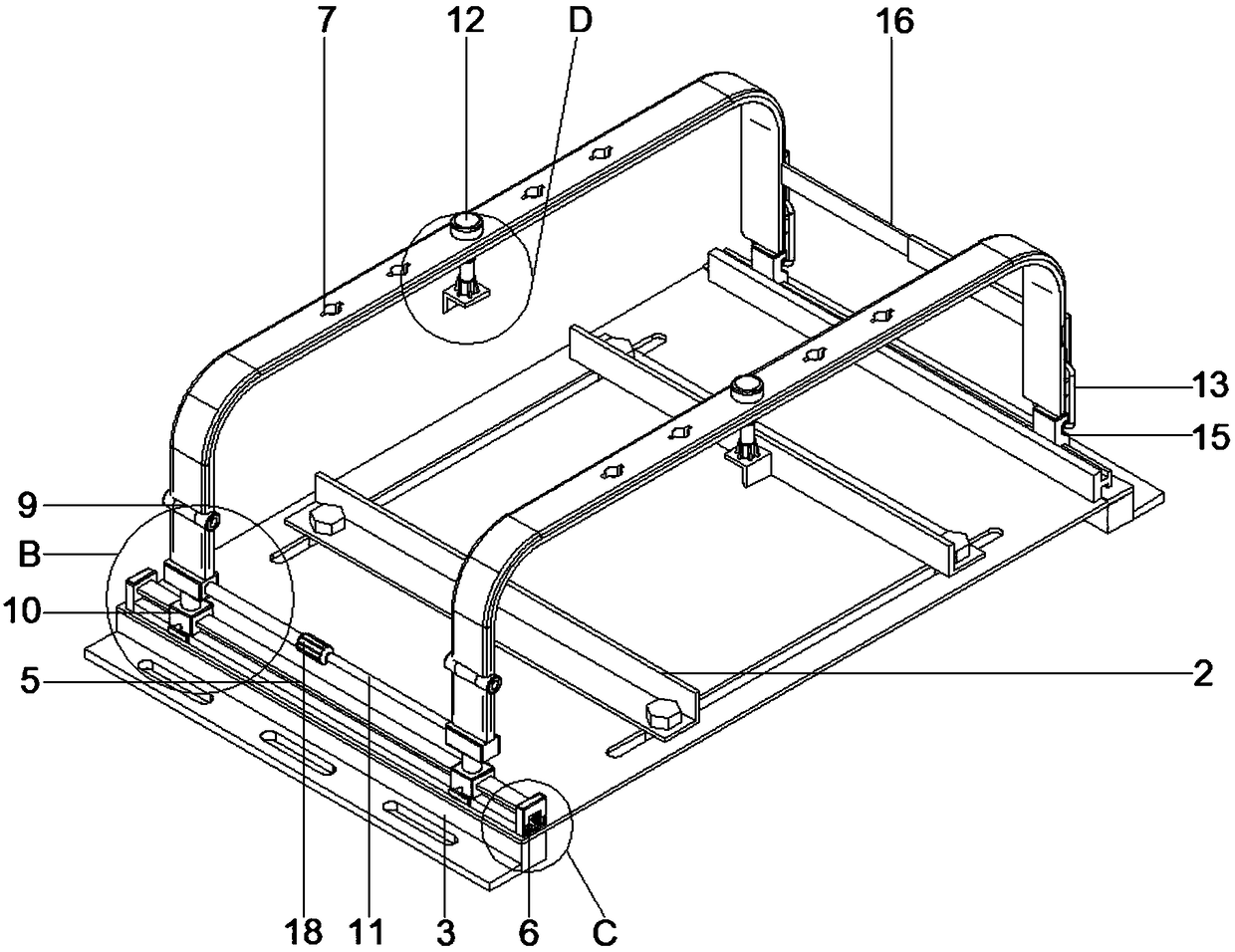

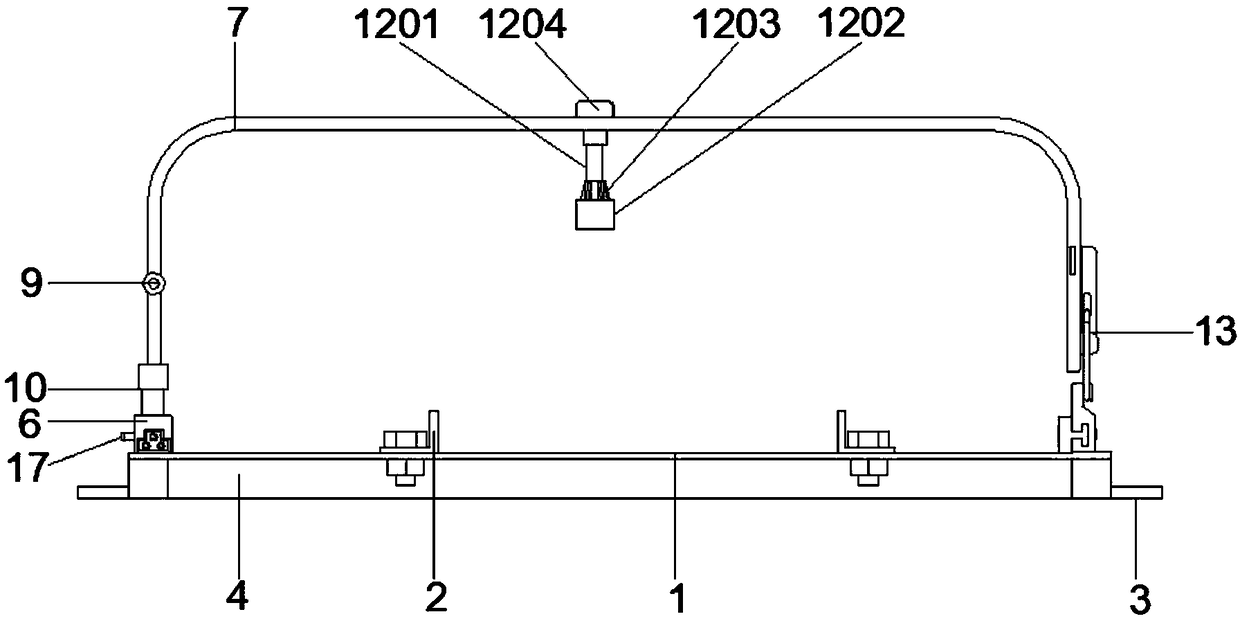

[0036]A quick fixture for workpieces of industrial drilling and milling equipment, including: a bottom plate 1, a limit plate 2, a fixing seat 3, a reinforcement plate 4, a first slide rail 5, a side fixing plate 6, a locking frame 7, a slider 8, and a rotating shaft 9. Connecting device 10, adjusting rod 11, clamping device 12, lockset 13, second slide rail 14, locking block 15, guide plate 16, locking handle 17, adjusting knob 18, locking bolt 19, connecting column 1001, Connecting block 1002, connecting plate 1003, bolt rod 1201, clamping plate 1202, connecting cylinder 1203, locking nut 1204, fixing plate 1301, locking handle 1302, pin shaft 1303, elastic rod 1304, sleeve 1305, locking buckle 1306 ; The bottom plate 1 is a rectangular plate structure; the limit plate 2 is arranged on the upper side of the bottom plate 1, and the limit plate 2 is connected with the bottom plate 1 by bolts; the fixed seat 3 is arranged on the side of the bottom plate 1, and the fixed seat 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com