Connection auxiliary structure for metal splicing plate, and connection method for metal splicing plate

An auxiliary structure and metal plate technology, applied in auxiliary welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problem of destroying the sheer strake structure, leading-out plates cannot be reused, repairing and grinding the arc-starting plate with a large workload and other issues to achieve the effect of ensuring the cutting effect, improving the cutting efficiency and reducing the difficulty of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

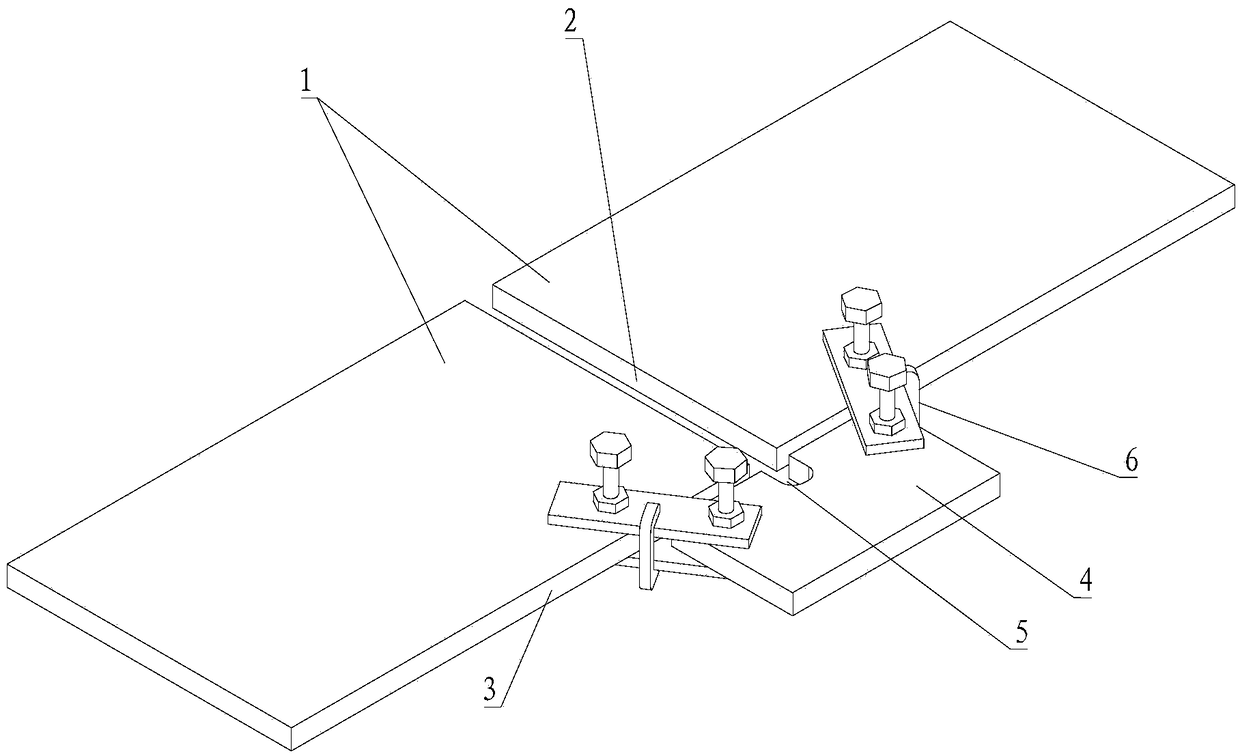

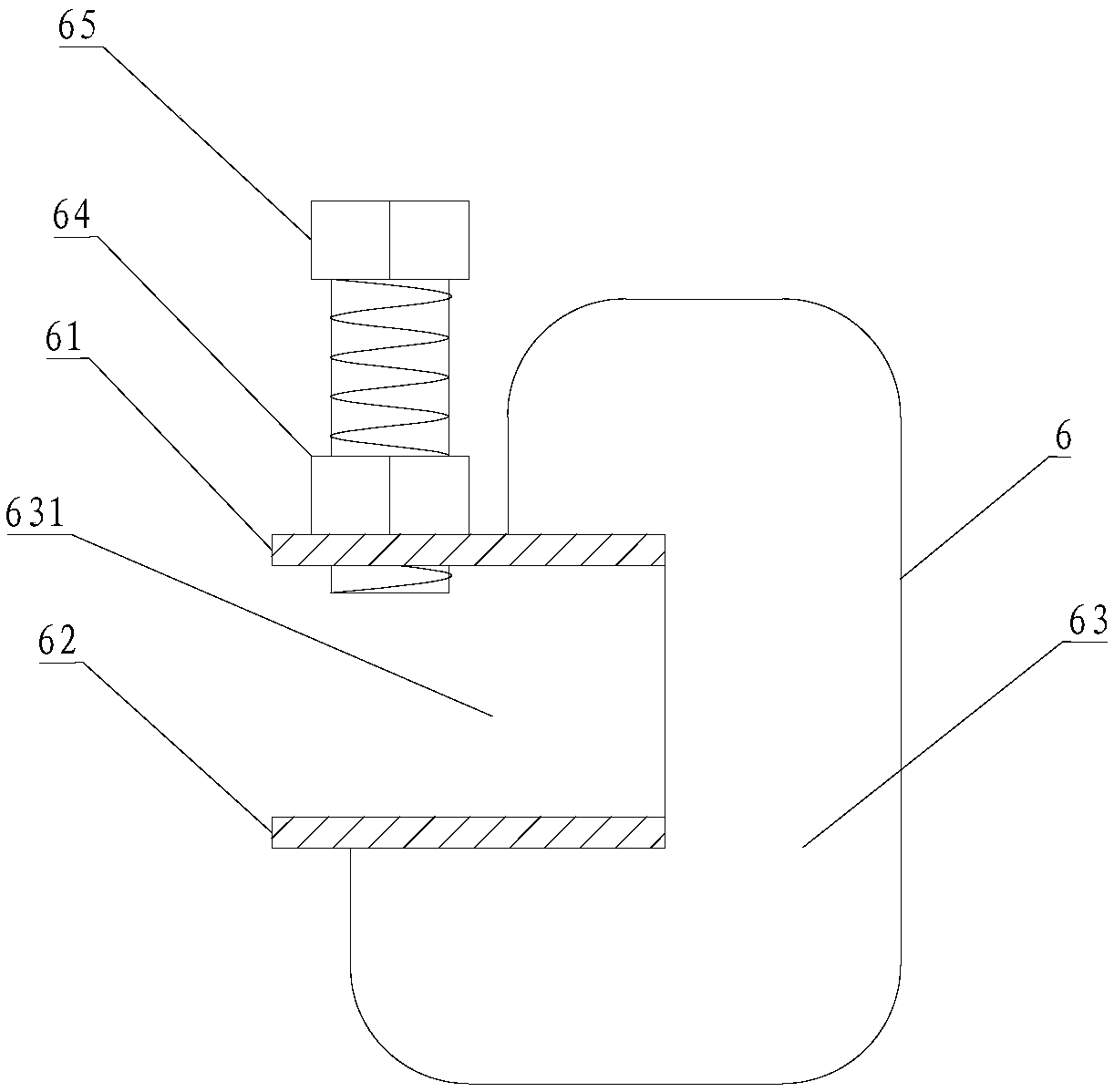

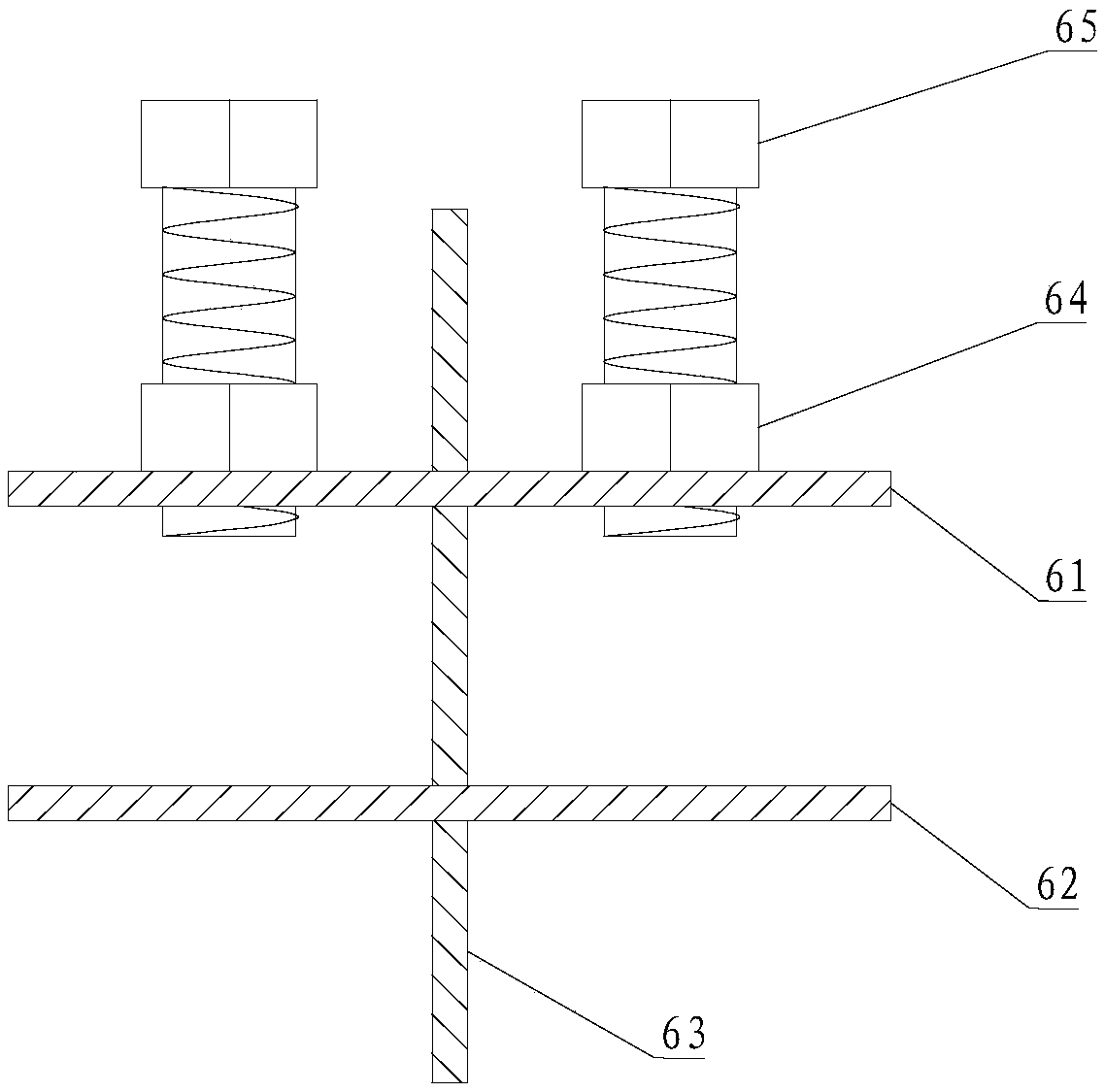

[0078] A method of using a connection auxiliary structure of metal puzzles to carry out metal puzzles, comprising the steps of:

[0079] Hoisting: adjust the gap between the base metals that need to be assembled to form a butt joint;

[0080] Positioning: Add connection auxiliary structures at the beginning and end of the butt joint, align the guide groove with the butt joint, connect the metal plate to the base material by clamping the card code, and maintain the distance between the metal plate and the base material 0.1mm-5mm;

[0081] Welding: starting from the guide groove on the metal plate at the beginning of the butt joint to form a weld, and welding to the guide groove on the metal plate at the end of the butt joint;

[0082] Cutting: use cutting equipment to cut the weld between the metal plate and the base metal;

[0083] Removal: loosen the clamping card code to separate the metal plate from the base material;

Embodiment 2

[0086] A method of using a connection auxiliary structure of metal puzzles to carry out metal puzzles, comprising the steps of:

[0087] Hoisting: adjust the gap between the base metals that need to be assembled to form a butt joint;

[0088] Positioning: Add connection auxiliary structures at the beginning and end of the butt joint, align the guide groove with the butt joint, connect the metal plate to the base material by clamping the card code, and maintain the distance between the metal plate and the base material 0.1mm-5mm;

[0089] Welding: starting from the guide groove on the metal plate at the beginning of the butt joint to form a weld, and welding to the guide groove on the metal plate at the end of the butt joint;

[0090] Cutting: use cutting equipment to cut the weld between the metal plate and the base metal;

[0091] Removal: Loosen the Liange clamping card code to separate the metal plate from the base material;

Embodiment 3

[0094] A method for metal jigsaw puzzles, comprising the steps of:

[0095] Hoisting: adjust the gap between the base metals that need to be assembled to form a butt joint;

[0096] Positioning: Add connection auxiliary structures at the beginning and end of the butt joint, align the guide groove with the butt joint, connect the metal plate to the base material by clamping the card code, and maintain the distance between the metal plate and the base material is 3mm;

[0097] Welding: starting from the guide groove on the metal plate at the beginning of the butt joint to form a weld, and welding to the guide groove on the metal plate at the end of the butt joint;

[0098] Cutting: loosen one of the clamping cards, and then use cutting equipment to cut the weld between the metal plate and the base metal;

[0099] Removal: loosen another clamping card to separate the metal plate from the base metal;

[0100] Grinding: Use grinding equipment to grind the weld between the base m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com