V-shaped drag positioning mechanism, material roll feeding device and material roll feeding positioning measurement method

A positioning mechanism and material roll technology, applied in the direction of measuring device, force/torque/work measuring instrument, winding strip, etc., can solve the problem of inaccurate positioning of AGV trolley, achieve convenient feeding, ensure concentricity, The effect of preventing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

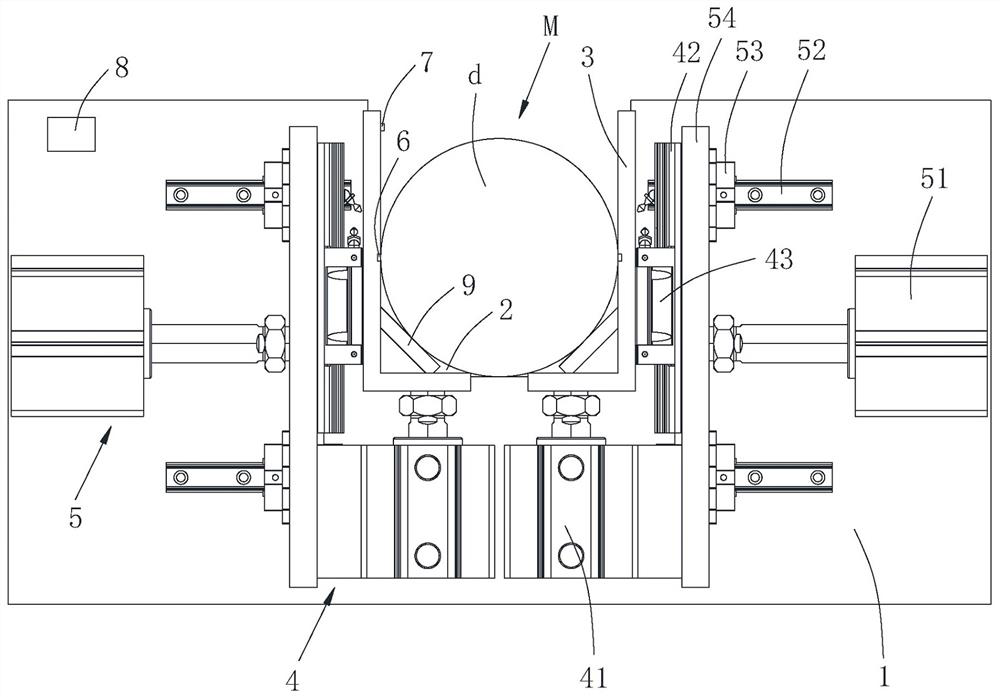

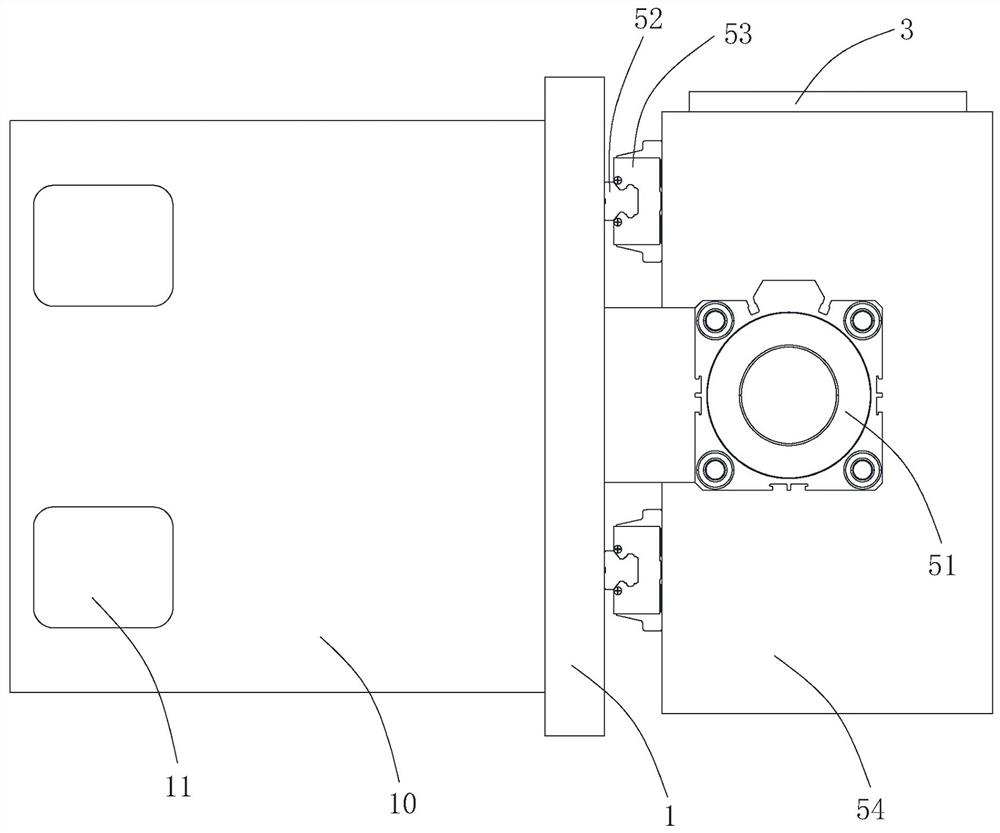

[0062] Such as figure 1 As shown, the V-shaped drag positioning mechanism of the present embodiment includes: a V-shaped drag plate 1 fixedly arranged, the top of the V-shaped drag plate 1 is provided with a V-shaped groove 2 for pre-carrying a roll d; The L-shaped clamps 3 on both sides of the groove 2, and the two L-shaped clamps 3 can perform lifting and translation movements on the V-shaped pallet 1; Position M, so that the coil d is coaxial with the inflatable shaft; the height of the L-shaped clamp dragging 3 moving up is ;

[0063] Among them, △H is the height difference before and after the lifting of the L-shaped clamp 3;

[0064] H is the vertical height between the L-shaped clip 3 and the axis of the air expansion shaft before lifting, which is a known constant;

[0065] D is the distance between the vertical sections of the two L-shaped clips 3, which is a measured value. Because the two L-shaped clips 3 are clamped on both sides of the material roll d, the dista...

Embodiment 2

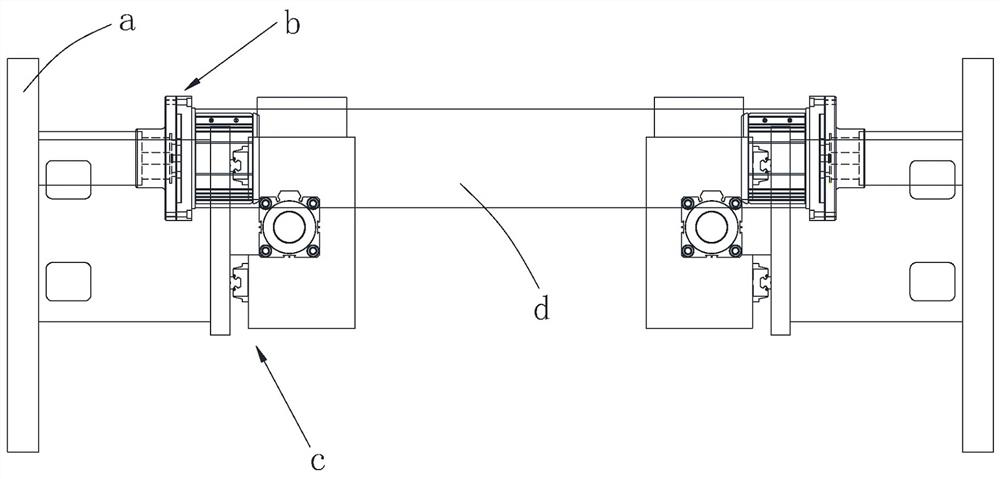

[0078] like Figure 1 to Figure 3 As shown, on the basis of Example 1, this Example 2 provides a lithium battery pole piece coil feeding device, including: a pair of support columns a, a pair of inflatable shaft mechanisms b, and a pair of V Type drag positioning mechanism c; wherein, the inflatable shaft mechanism b is arranged on the corresponding support column a, and the inflatable shaft mechanism b can extend laterally to the loading station M so that the inflatable shaft can expand and tighten the positioning material roll d; V The type drag positioning mechanism c is set on the corresponding support column a; the two translation components 5 on the same side translate the corresponding end of the clamping material roll d in opposite directions, and the corresponding lifting component 4 moves up synchronously to push the corresponding L-shaped clamp drag 3 supports The material roll d is moved up to the feeding station M, so that the material roll d in the V-shaped groov...

Embodiment 3

[0080] like Figure 1 to Figure 3 As shown, on the basis of Embodiment 2, this Embodiment 3 provides a positioning measurement method for material roll loading, including: two translation components 5 respectively push the corresponding lifting component 4 to translate to the V-shaped groove 2, so as to push the two L-shaped The gripper 3 translates the clamped material roll d in opposite directions; the pressure sensor 6 embedded in the L-shaped gripper 3 is pressed and triggered to send a signal to the controller 8, and the controller 8 controls the translation component 5 to stop translation; the distance sensor 7 measures the two L-shaped The spacing D of the vertical section of the clamping drag 3 is used to measure the actual diameter of the end of the material roll d; the controller 8 receives the data of the measured value D of the spacing and calculates , so as to control the lifting component 4 to drive the L-shaped clamp 3 to move up to a height of △H, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com