A method of manufacturing a high-strength silo fence structure

A manufacturing method and silo technology, applied in the direction of manufacturing tools, welding/welding/cutting items, welding equipment, etc., can solve the problems of welding deformation of fence structural parts and poor welding accessibility, etc. Small welding deformation, the effect of controlling welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for manufacturing a high-strength silo fence structure, which is carried out sequentially according to the following steps:

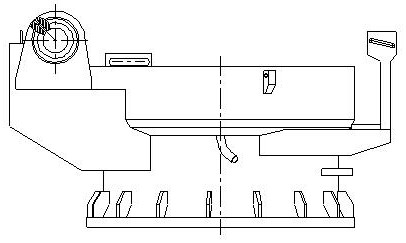

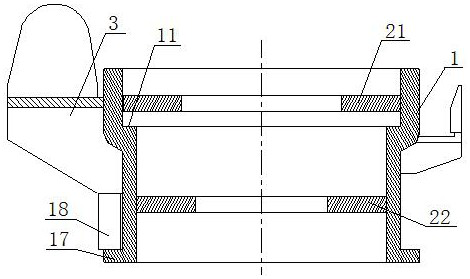

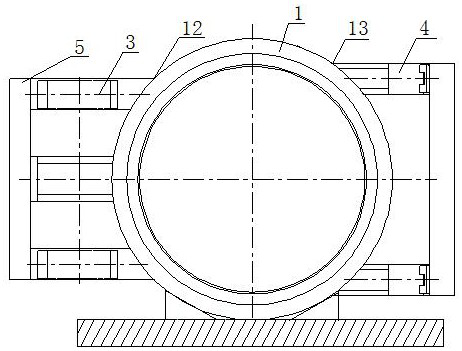

[0048] 1. First place the cylinder body 1 on the assembly platform, draw the assembly line of No. 1 anti-deformation support tool 21 and No. 2 anti-deformation support tool 22 along the inner circumference of the cylinder body 1, and then assemble the No. 1 anti-deformation support tool by spot welding according to the line Supporting tooling 21, No. 2 anti-deformation supporting tooling 22, and then determine the assembly center line of the buffer bracket 3 and the elastic device mounting seat 4, and arrange the support block 18 for supporting the buffer bracket 3 on the flange surface 17 of the cylinder body 1, Then the buffer bracket 3 is correspondingly assembled on one side of the cylinder body 1, and the elastic device mounting seat 4 is correspondingly assembled on the other side of the cylinder body 1, and then the channel steel t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com