Medium-frequency plasma cleaning device

A plasma and cleaning device technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of thermal effect of material surface damage, damage to processing parts, etc., and achieves good fast contact, easy control, and is conducive to control purposes. effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make it easier for those skilled in the art to understand the solution of the present invention, the technical solution of the present invention will be further specifically described in conjunction with specific embodiments.

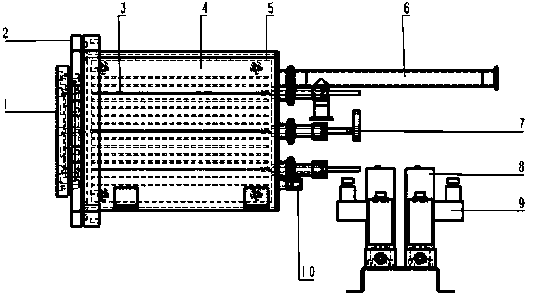

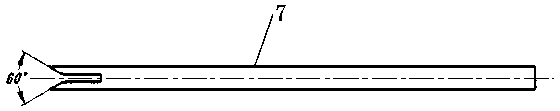

[0012] like figure 1 , figure 2 As shown, the present invention is an intermediate frequency plasma cleaning device, comprising: an air intake device, a plasma generating device, a vacuum chamber, and an air extraction pipeline 6, and the air intake device includes an air inlet 10, an MFC mass flow meter 8, Electromagnetic valve 9, the plasma generating device includes positive and negative electrodes and PWM pulse width modulation power supply, the positive and negative electrodes include electrode terminal 7, electrode mounting plate 5, electrode tray 3, and the vacuum chamber includes a window flange 1 , the vacuum chamber door 2, the vacuum chamber body 4, and the electrode terminal 7 adopts a crocodile-mouth socket design. Thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com