Barreled water bucket inner cavity wall automatic cleaning machine

An automatic washing machine and barreled water technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning of the inner wall of the bucket, unstable operation of equipment, and large amount of cleaning liquid. Achieve high practical value, economical and practical structure, save time and labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

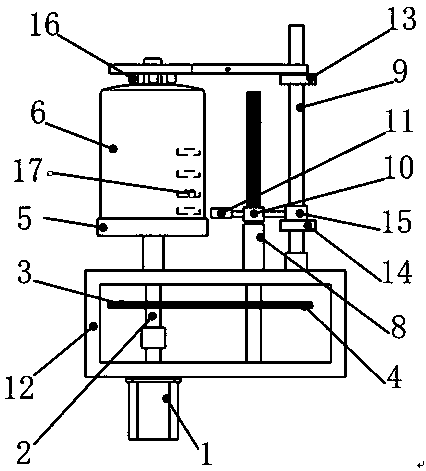

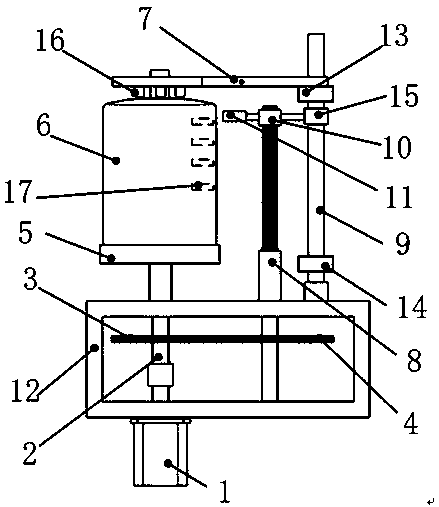

[0019] The implementation process of the present invention will be described below in conjunction with the accompanying drawings.

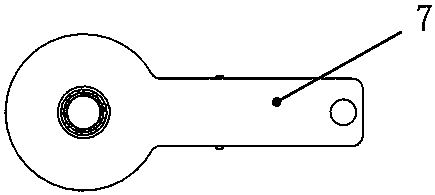

[0020] Such as figure 1 , a barreled water automatic cleaning machine for the inner wall of the bucket, which consists of a motor 1, a shaft 2, a small gear 3, a large gear 4, a rotating platform 5, a bucket 6, a bucket mouth bracket 7, a lead screw 8, a guide rail 9, and a nut 10. Composition of magnet 11, box body 12, up travel switch 13, down travel switch 14, slider 15, boss 16, magnetic cleaning bag 17;

[0021] The motor 1 is connected with the shaft 2 through a coupling, and the motor 1 is fixed on the outside of the box body 12; the other end of the shaft 2 is fixed with a rotating platform 5, and the shaft 2 is connected with a pinion 3 through a key, and the shaft 2 is connected to the box body through a bearing. 12 support connection; the water bucket 6 is vertically placed on the rotating platform 5 according to the bottom of the buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com