Raw material uniform stirring equipment for color powder proportioning

A raw material and toner technology, which is applied in the field of raw material mixing equipment for toner blending, can solve the problems of toner dust, difficulty in automatic discharge, high price, etc., and achieve the effect of reducing dust and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

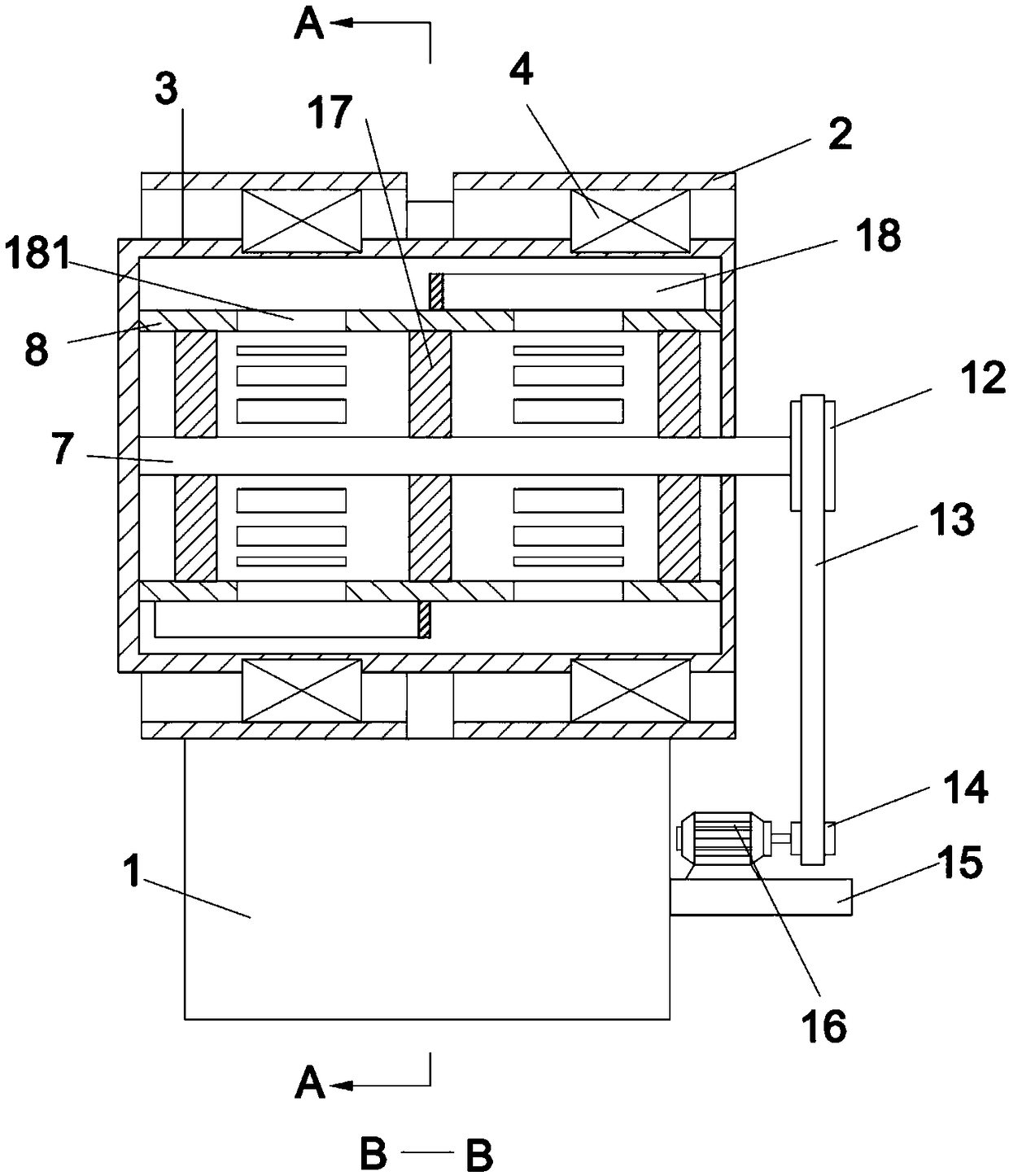

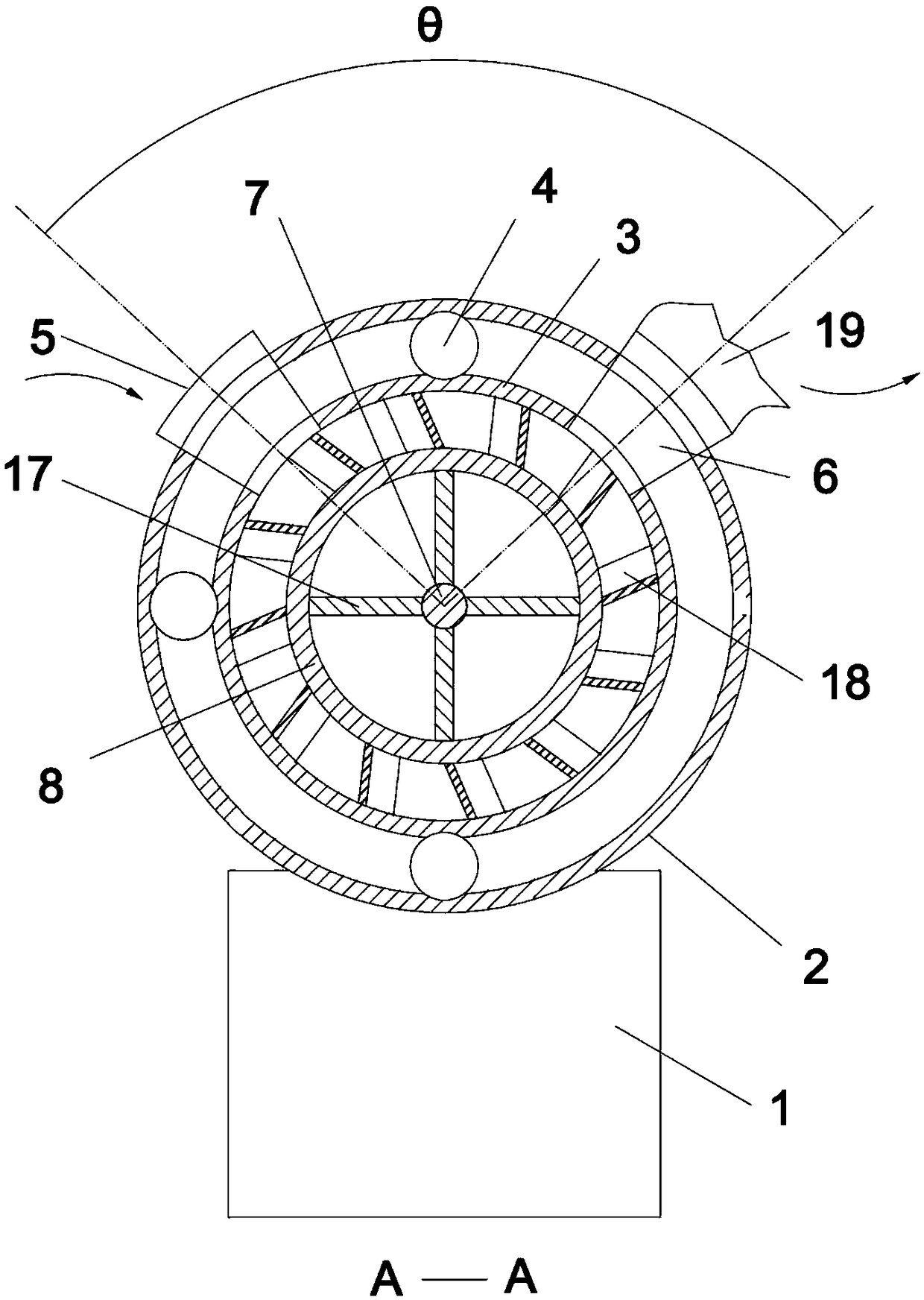

[0024] like figure 1 and figure 2 As mentioned above, the present invention includes a base 1 that supports the whole and an outer cylinder 2 fixed on the base 1. The inner wall of the outer cylinder 2 is rotatably connected to the inner cylinder 3 through the rolling core 4, and the surface of the inner cylinder 3 is provided with a feeding port 5 and a discharging port. Port 6, the diameter of the inlet port 5 and the outlet port 6 are both 20-35cm (preferably 25cm), and the inlet port 5 and the outlet port 6 are communicated with the interior of the inner cylinder 3, such as figure 1 , the left end of the rotating shaft 7 is rotatably connected to the left side wall of the inner cylinder 3, the right end of the rotating shaft 7 extends laterally through the inner cylinder 3 from the right side wall of the inner cylinder 3, and is connected to the pulley 12, and the inner cylinder 3 is provided with a roller 8 , the drum 8 is fixedly connected to the rotating shaft 7, and ...

Embodiment 2

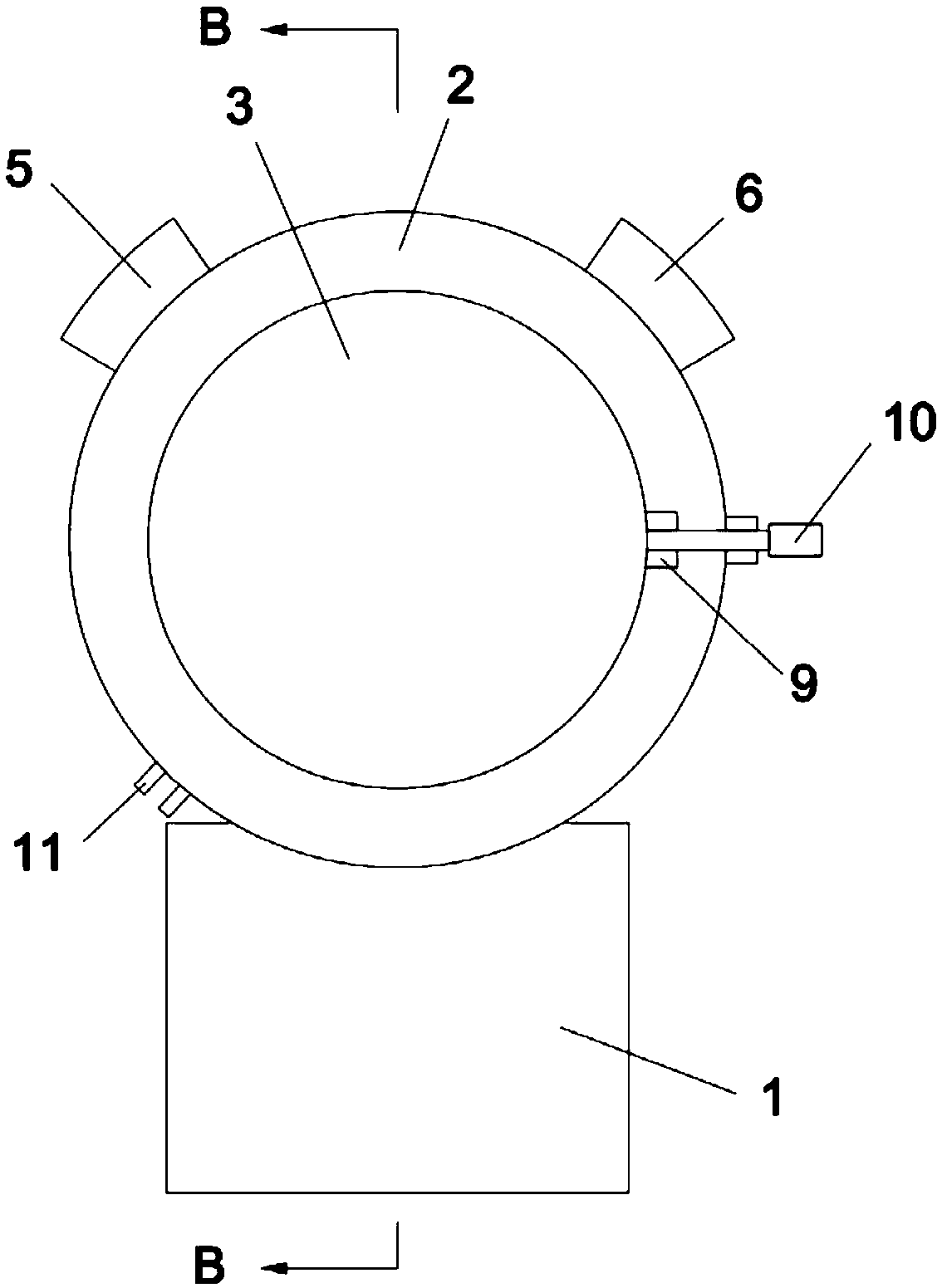

[0035] see Figure 4 In this embodiment, the handle 10 and the buckle 11 in Embodiment 1 are replaced by a friction wheel 20 and a limit switch 21, the outer wall of the inner cylinder 3 is in frictional contact with the friction wheel 20, and the outer wall of the inner cylinder 3 is also provided with a friction wheel 20 limit switch 21, the friction wheel 20 can be driven by a motor, the motor is installed on the base 1, the number of limit switches 21 is two, and the position of the limit switch can be related to the discharge port 5 and the feed port 6 The position of the inner cylinder 3 can be switched between the discharge position and the stirring working position.

[0036] The rotation of the inner cylinder 3 is driven by the friction wheel through the frictional force. When the limit switch 21 on the inner cylinder touches the friction wheel 20, the friction wheel 20 stops rotating, and the inner cylinder 3 is in the stirring working position at this time; When fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com