Ultrasonic dental unit without tooth damage

An ultrasonic and dental scaler technology, which is applied to cleaning teeth, cleaning methods using liquids, dentistry, etc., can solve the problems of easy damage and wear of the working tip, reducing the convenience and safety of the teeth cleaning process, and inconvenient operation. , to achieve the effect of improving safety and comfort, avoiding easy breakage, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

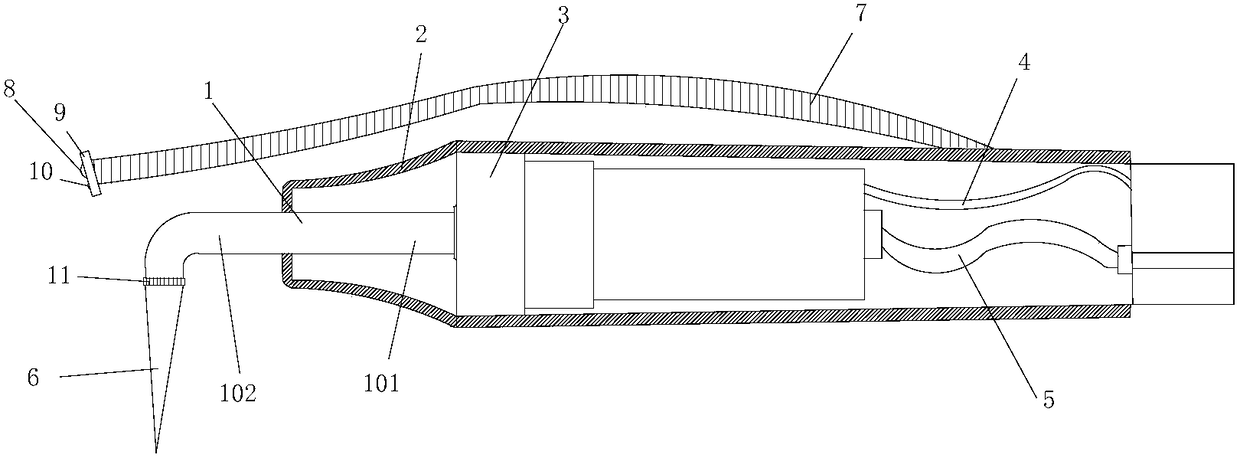

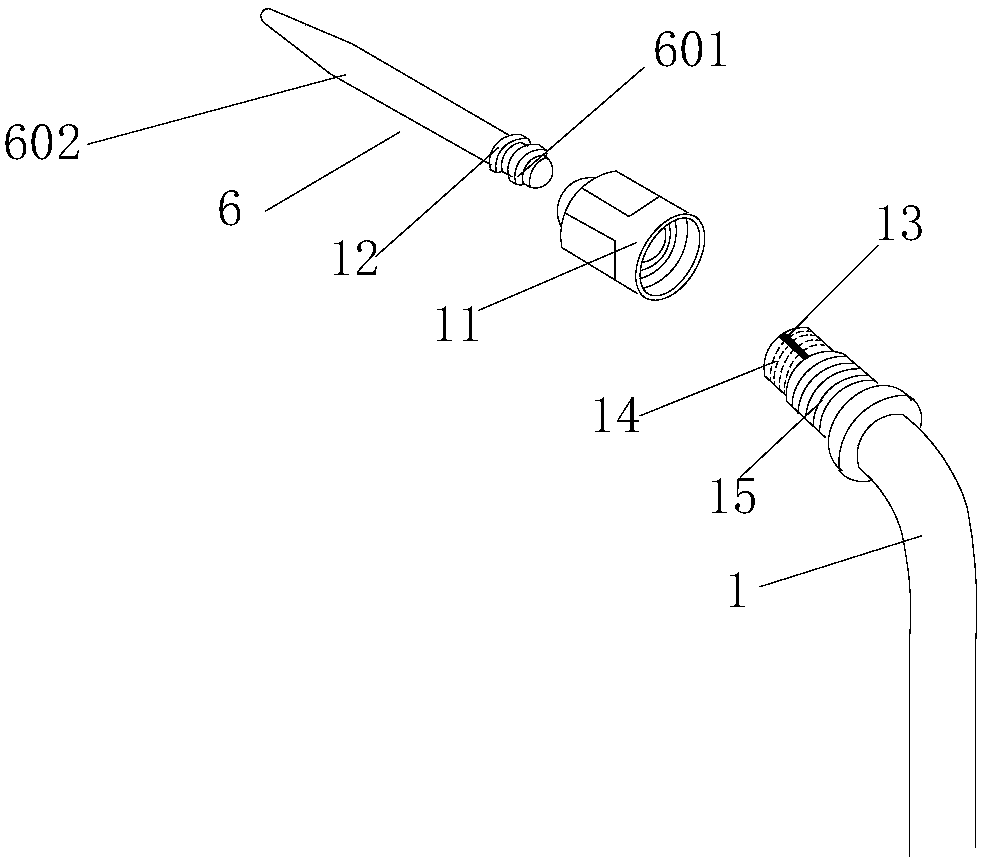

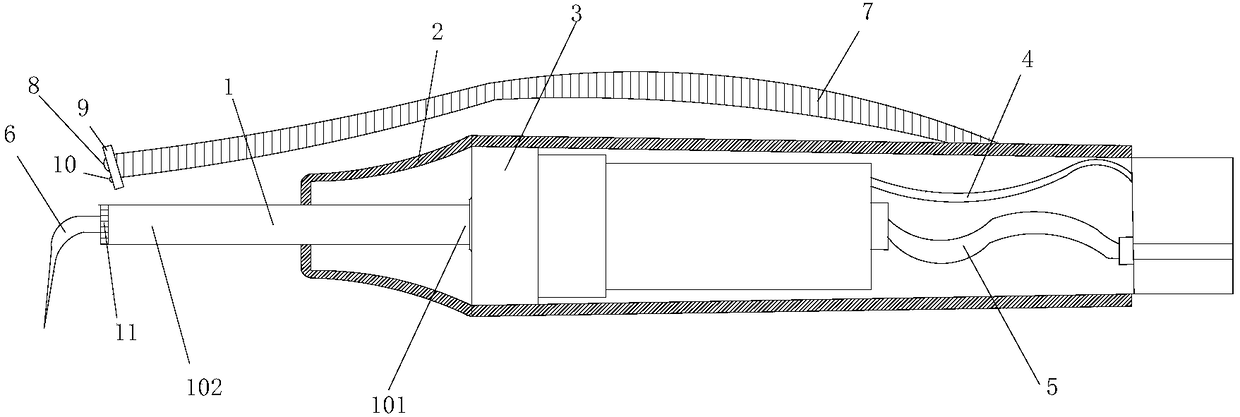

[0052] like Figure 1 to Figure 2 As shown, an ultrasonic dental scaler described in this embodiment that does not damage teeth includes a handle housing 2 and a transducer 3 disposed in the handle housing 2, and the front end of the transducer 3 is fixedly connected to the horn. The first end 101 and the second end 102 of the horn extend out of the handle shell 2; the second end 102 of the horn is connected to a pair of working tips 6 for cleaning teeth.

[0053] In this embodiment, the ultrasonic tooth scaler uses ultrasonic tooth cleaning technology to perform tooth cleaning. like figure 1 As shown in , the tooth cleaning handle of the present invention also includes electric wires 4 and water pipes 5, and the high-frequency and high-energy vibrations generated by ultrasonic waves are used to crush the calculus and stains on the tooth surface through the smooth working tip. Same as the prior art, in this embodiment, the working tip 6 is provided with a water outlet to gen...

Embodiment 2

[0072] This embodiment serves as a supplement to the realization of the limiting device in the first embodiment: the positioning ring in the limiting device is a snap ring that fits on the connecting end of the working tip and is used to engage with the positioning groove on the mounting hole. The snap ring is provided with an elastic recovery device (such as a snap spring), so that the positioning ring can be retracted toward the center of the connection end when it is subjected to external pressure, and returns to its original position when the external force is removed, that is, the positioning ring passes through the connection. The deformation of the end fits into the positioning groove. The position limiting function can also be realized through the elastic engagement of the snap ring and the positioning groove.

Embodiment 3

[0074] This embodiment is further supplemented as the realization of the limiting device of the above-mentioned embodiment: in order to realize the limit of the circumferential movement of the working tip 6 by the mounting hole 13 at the same time, the limiting device uses a protrusion set on the outer surface of the connecting end 601 of the working tip. Scattered positioning blocks and positioning grooves on the inner wall of the mounting hole that match the positioning blocks are used to achieve the limiting effect. The matching method and installation process of the positioning block and the positioning groove in this embodiment can be performed with reference to the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com