Conveyer belt type floor brush module with dehairing function

A conveyor belt and functional technology, which is applied in the field of conveyor belt-type floor brush modules, can solve the problems of foreign matter such as hair or silk thread entanglement, affecting the working efficiency of cleaning equipment, and small contact cleaning surface, etc., to achieve increased cleaning surface and automatic hair removal , Improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

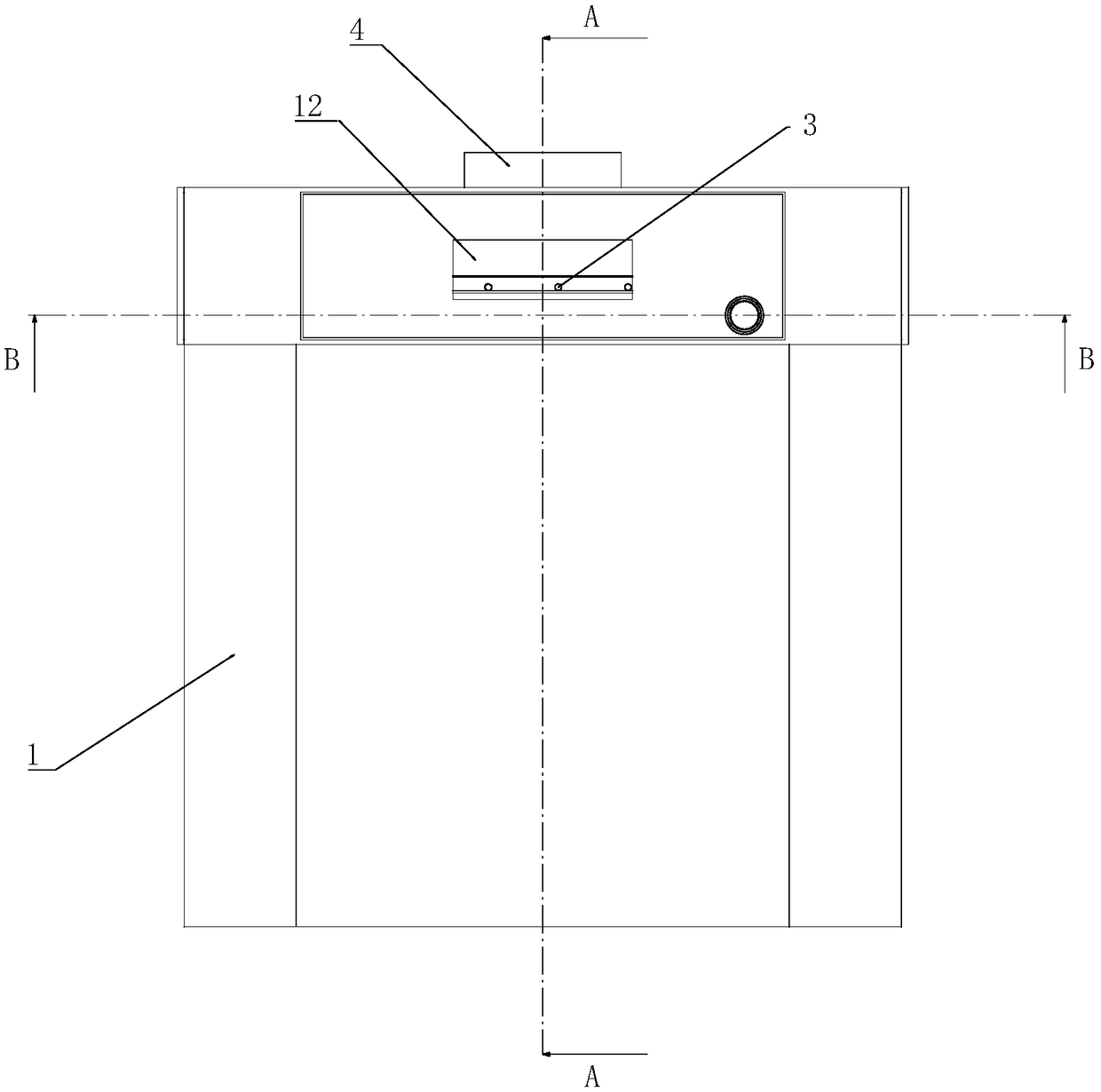

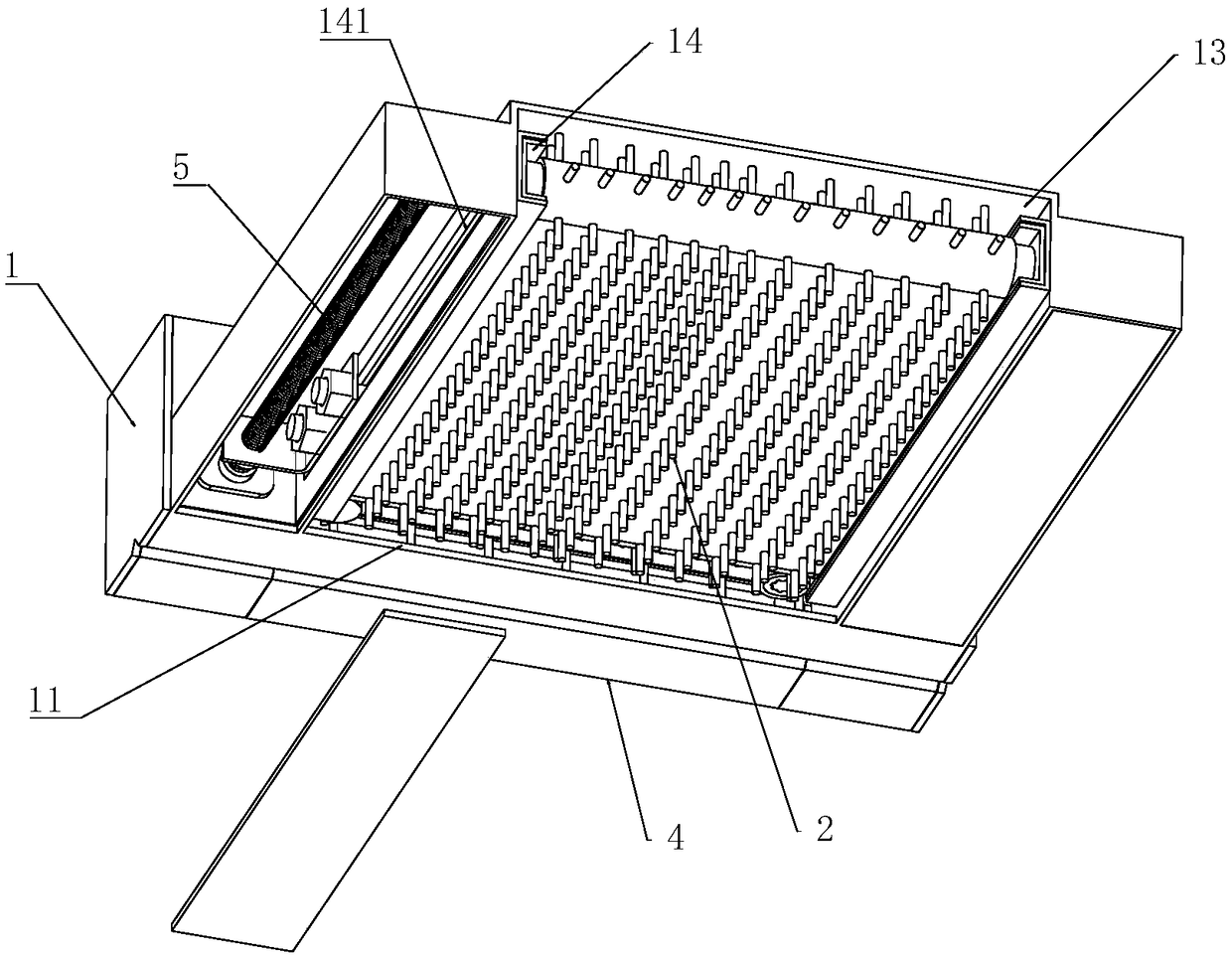

[0027] refer to Figure 1 to Figure 5 , a conveyor belt-type ground brush module with hair removal function of the present invention includes a housing 1 and a ground brush assembly 2 installed in the housing 1, the ground brush assembly 2 includes a cleaning conveyor belt 21, a drive The cleaning conveyor belt 21 is a first driving structure that performs rotary motion along the front and rear directions. The outer surface of the cleaning conveyor belt 21 is provided with a number of cleaning flocking bundles 211, and the housing 1 corresponds to the position below the cleaning conveyor belt 21. A cleaning port 11 that allows the cleaning and planting bundle 211 to pass through is provided, and a hair removal device 3 adjacent to the ground brush assembly 2 is provided in the housing 1, and the hair removal device 3 includes several hair removal and planting Bundle 31, the second drive structure that drives the hair removal and flocking bundle 31 to reciprocate or rotate alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com