Cut tobacco flavoring device

A shredded tobacco and cylinder technology, which is applied in the field of shredded tobacco flavoring device, can solve the problems of low production efficiency, time-consuming and laborious, etc., and achieve the effects of high production efficiency, large amount of flavoring, and good flavoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

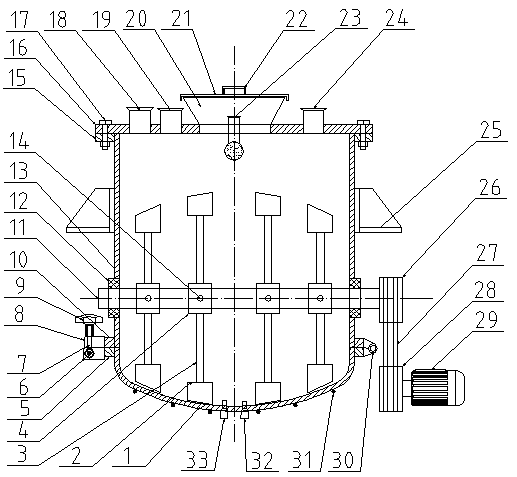

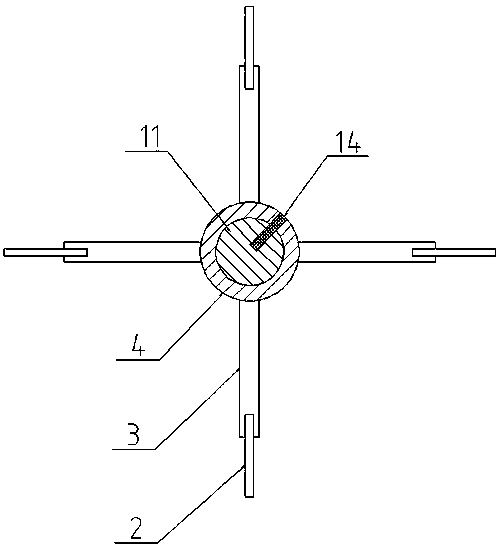

[0027] see Figure 1-5 , the present embodiment provides a shredded tobacco flavoring device, comprising a lower head 1, a stirring blade 2, a stirring shaft 11, a cylinder body 13, an upper sealing plate 16, a feeding hopper 20, a support 25, and a reduction motor 29; The upper part of the lower head 1 and the head flange 5 are fixedly connected by welding, and the lower head 1 is a stainless steel butterfly head; the lower part of the cylinder 13 is fixedly connected with the lower flange 10 of the cylinder, and the lower flange of the cylinder 10 is connected with the right side of the head flange 5 through a hinge 30, the left side of the head flange 5 is provided with a joint base 6, and a joint bolt 7 is installed on the joint base 6, and the joint base 6 and the joint bolt 7 pass through the second The bolt connection assembly 34 is connected, and the torx handle 9 is installed on the union bolt 7; the lower head 1 and the cylinder body 13 are connected through the unio...

Embodiment 2

[0034] This embodiment is consistent with the first embodiment in terms of structure and working mode. The number of hubs 4 provided on the stirring shaft 11 is not limited. Preferably, the number of hubs 4 provided is four.

Embodiment 3

[0036] The structure of this embodiment is the same as that of Embodiment 1. The cleaning port 23 is provided with a spray ball, and the liquid essential oil used for flavoring the shredded tobacco is evenly sprayed on the shredded tobacco in the barrel 13 through the spray ball to improve the flavoring effect.

[0037] The working principle of the present invention is:

[0038] When the present invention is working, shredded tobacco is added from the feed hopper 20, spices are added into the spice inlet 19, and the geared motor 29 rotates to drive the stirring shaft 11 to rotate at a constant speed. The heating wire 31 heats the lower head 1 to speed up the fragrance adjustment effect; when it is necessary to add liquid flavoring essential oil for fragrance adjustment, the prepared essential oil is added into the cylinder body 13 through the cleaning port 23, and the spray ball sprays the essential oil evenly On the shredded tobacco, the agitator rotates at the same time to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com