Heat-dissipating power distribution cabinet for electric equipment

A heat-dissipating technology for electrical equipment, applied in the field of heat-dissipating power distribution cabinets for electrical equipment, can solve problems such as incomplete heat dissipation and equipment aging, and achieve the effects of increasing the level of height, facilitating movement, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

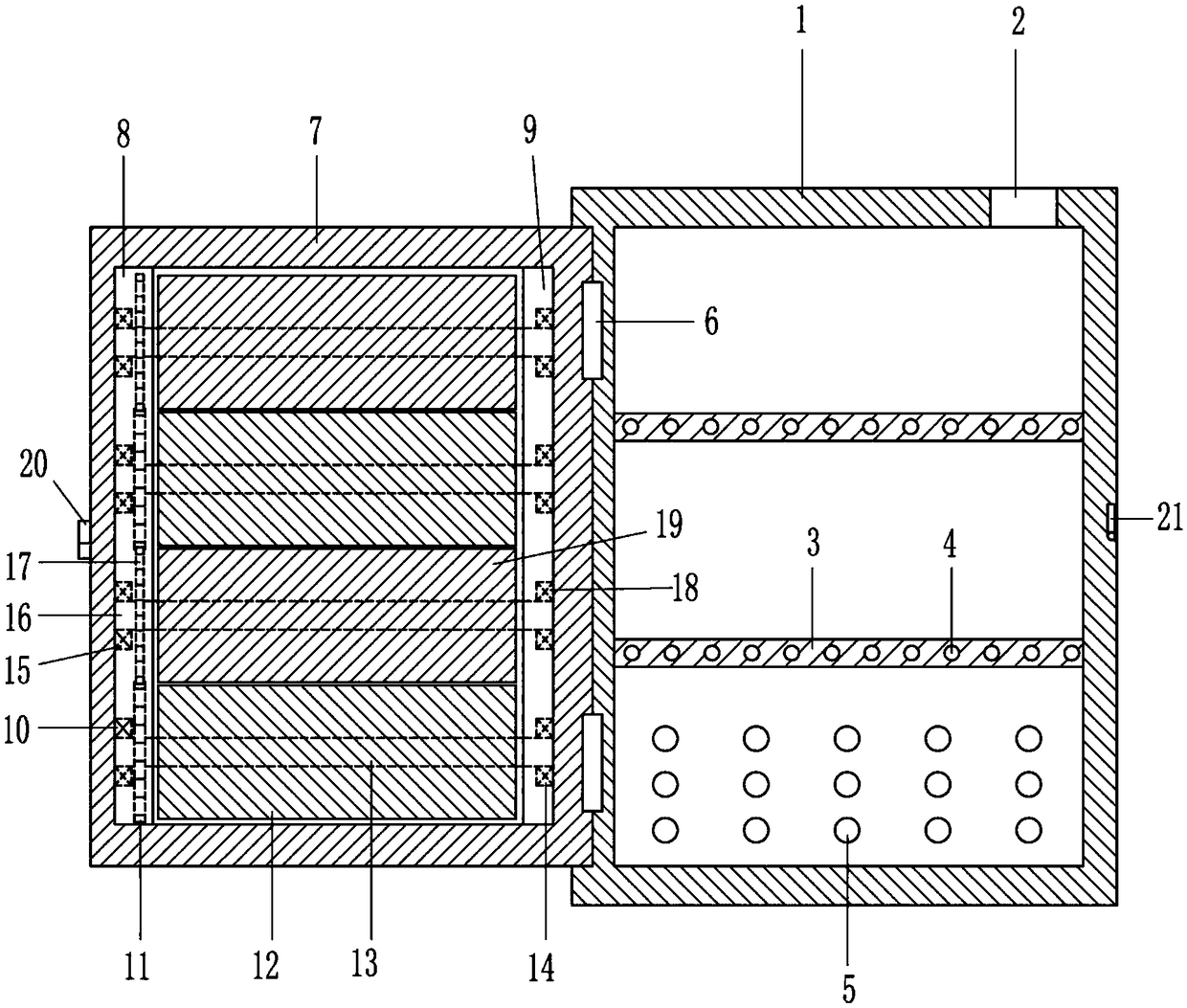

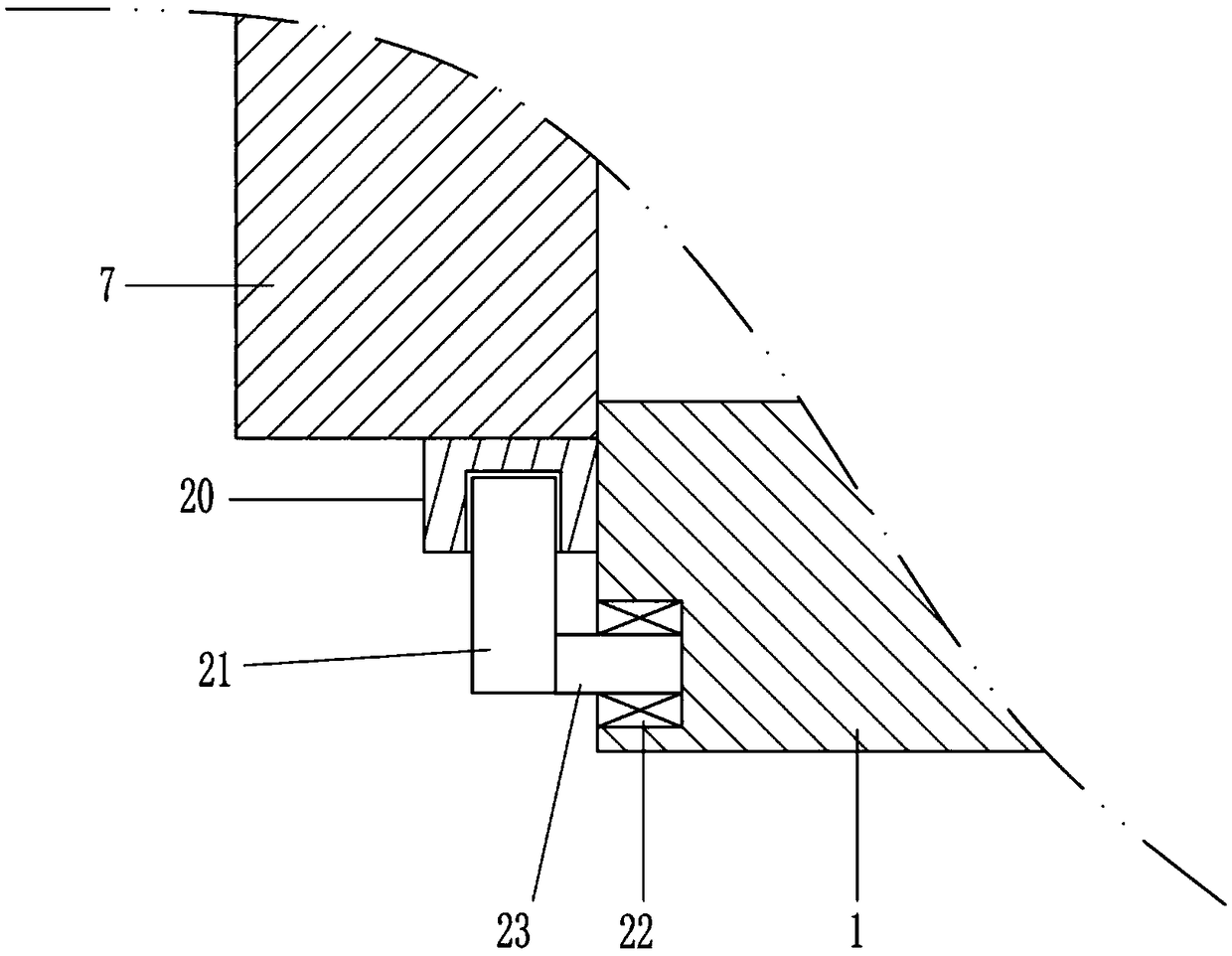

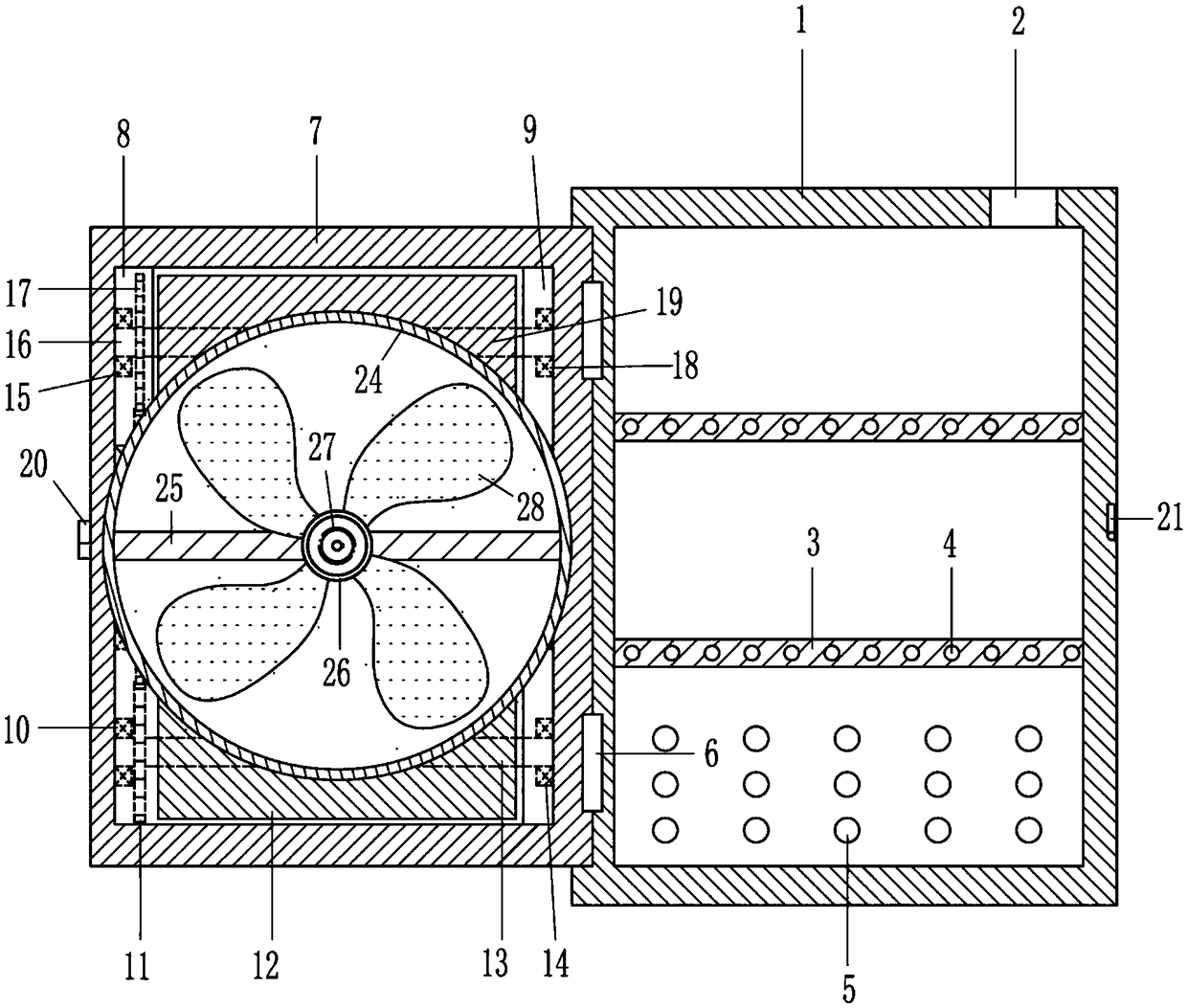

[0024] A cooling type power distribution cabinet for electrical equipment, such as Figure 1-8 As shown, it includes an electrical box 1, a mounting frame 3, a first hinged frame 6, an opening and closing frame 7, a first bearing seat 10, a first gear 11, a first opening and closing leaf 12, a first rotating shaft 13, and a third bearing Seat 15, third bearing seat 15, second rotating shaft 16, second gear 17, fourth bearing seat 18, second opening and closing leaf 19, clamping groove body 20, clamping rod 21, fifth bearing seat 22 and third Rotating shaft 23; the top of the electrical box 1 is provided with an inlet 2 connected to the power supply line; the mounting frame 3 is fixedly connected to the inner wall of the electrical box 1 in turn, and the mounting frame 3 is evenly provided with mounting holes 4 for connecting electrical equipment; the electrical box 1. The inner wall is evenly provided with cooling holes 5 for cooling electrical equipment; the first hinged fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com