Low-pollution combustion chamber for direct injection of multi-point lean oil

A combustion chamber and low-pollution technology, applied in the direction of combustion chambers, continuous combustion chambers, combustion methods, etc., can solve problems such as difficulty in ensuring rapid and sufficient mixing, reduced combustion efficiency, and poor combustion, so as to reduce the risk of burning and improve Combustion efficiency, effects of avoiding flashback and spontaneous combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

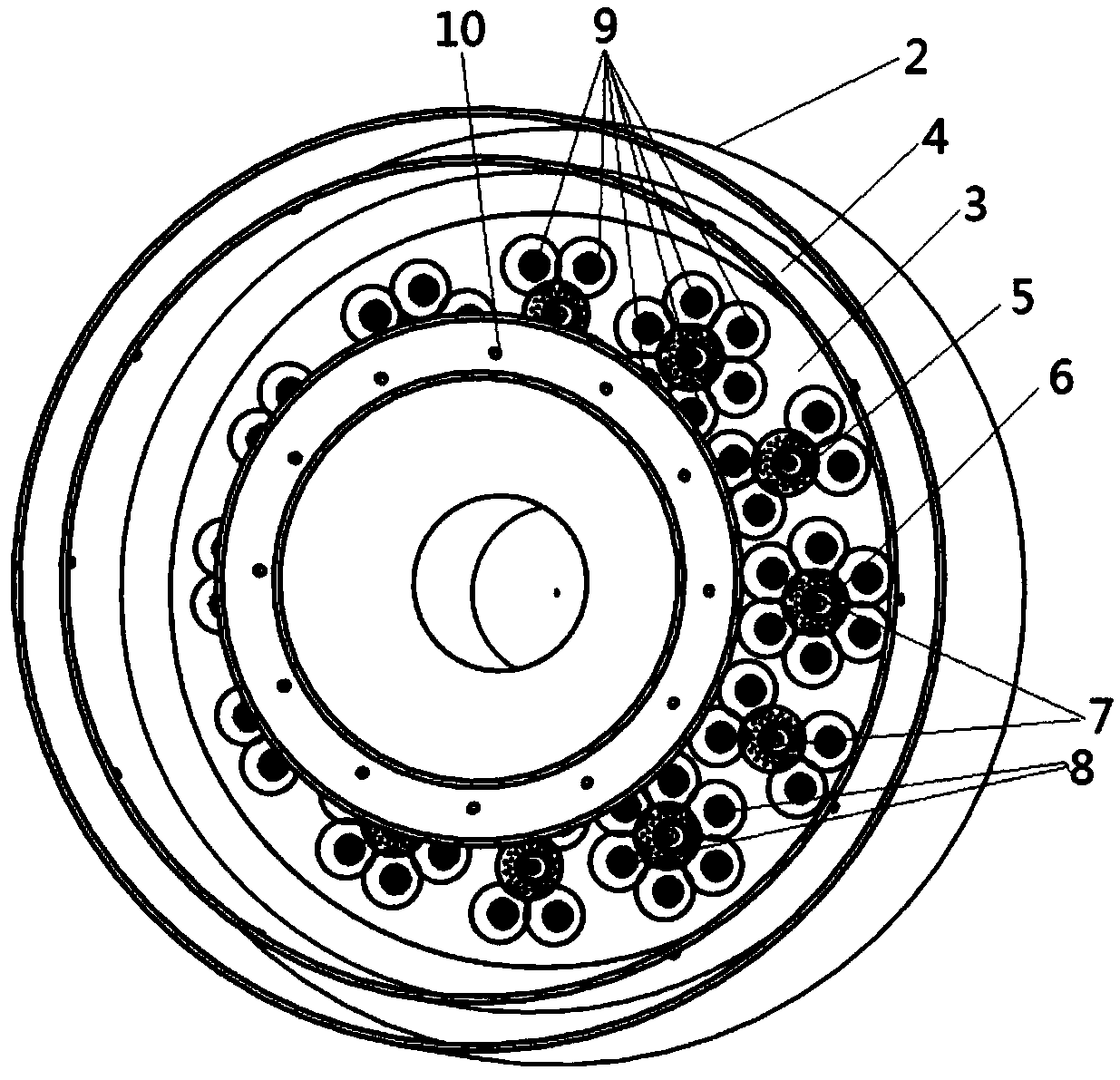

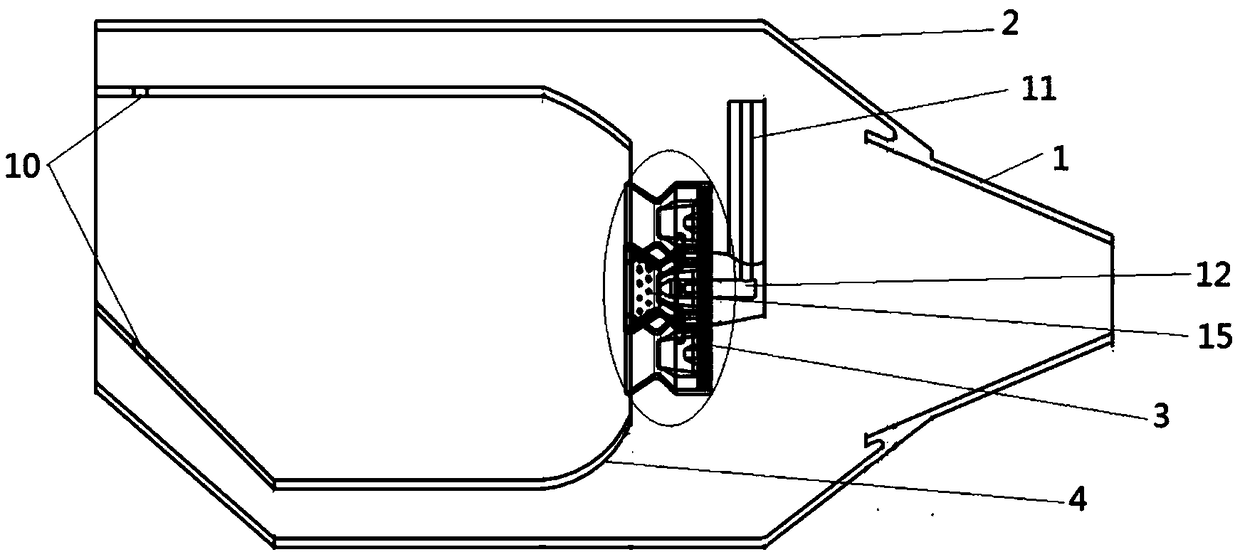

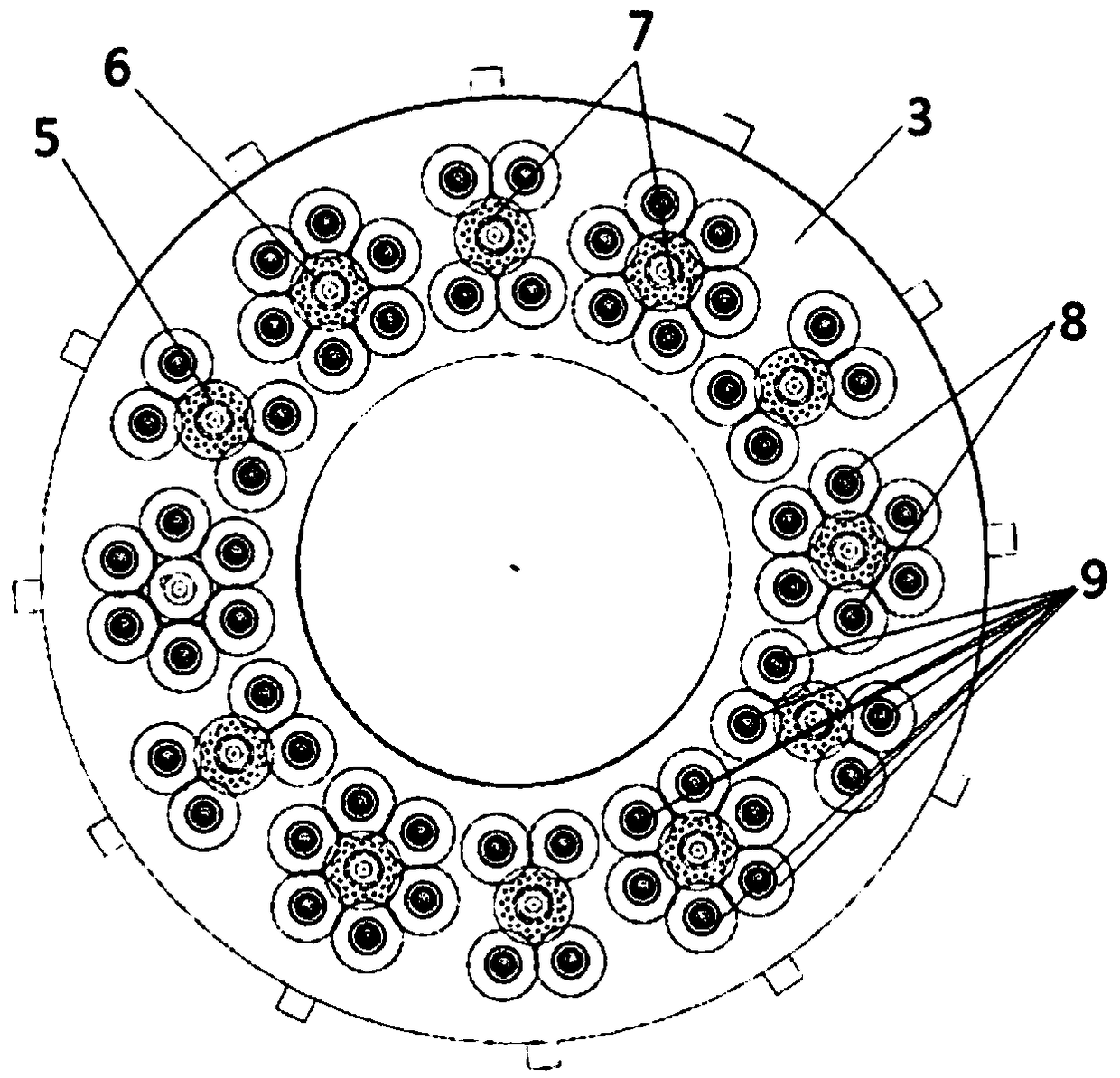

[0034] Such as Figure 1~2 As shown, the present invention provides a low-pollution combustor based on multi-point lean fuel direct injection, including a diffuser 1 , a combustor case 2 , a combustor head 3 , and a flame tube 4 . After being compressed by the compressor, the high-speed airflow is decelerated and diffused by the diffuser 1, and then divided into two streams, one enters the inner and outer annular channels formed by the combustion chamber casing 2 and the wall surface of the flame tube 4, and the other passes through the combustion chamber head 3 , into the flame tube 4 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com