Ultra-high-temperature butterfly valve

An ultra-high temperature, butterfly valve technology, used in lift valves, valve details, valve devices, etc., can solve the problems of frequent replacement, wear, product damage, etc., and achieve the effect of increasing durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

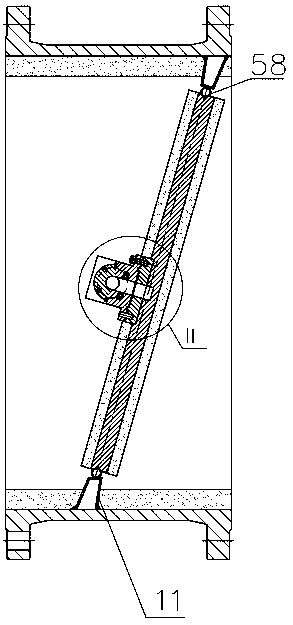

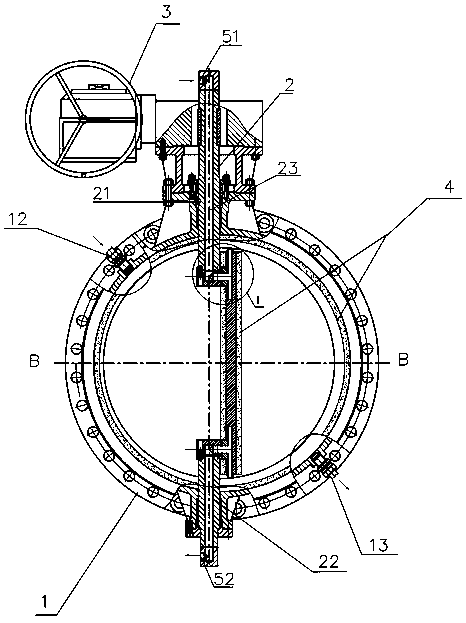

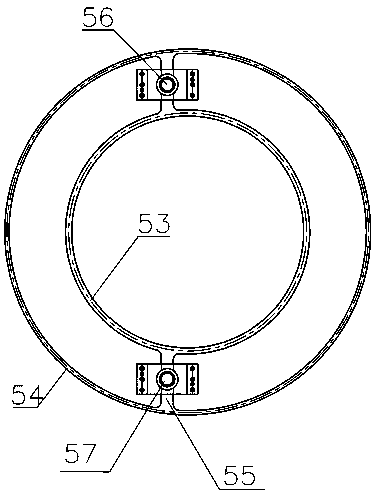

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an ultra-high temperature butterfly valve includes a valve body 1, the valve body 1 is provided with a valve stem 2, the valve stem 2 is also provided with a butterfly plate, and the upper end of the valve stem 2 is also connected with a The operating mechanism 3, the flow channel of the valve body 1 and the outer surface of the butterfly plate are provided with a wear-resistant and heat-insulating lining 4, and the inner wall of the flow channel of the valve body 1 is also provided with a valve body sealing ring 11, The valve body sealing ring 11 is a U-shaped hollow structure, the valve body sealing ring 11 is higher than the wear-resistant and heat-insulating lining 4 surfaces in the flow channel of the valve body 1 and is inclined, and the butterfly plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com