Waste weft thread end settlement collection device suitable for looms

A collection device, loom technology, applied in auxiliary equipment for weaving, textile, textile and paper making, etc., can solve the problem of waste thread end polluting the environment and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

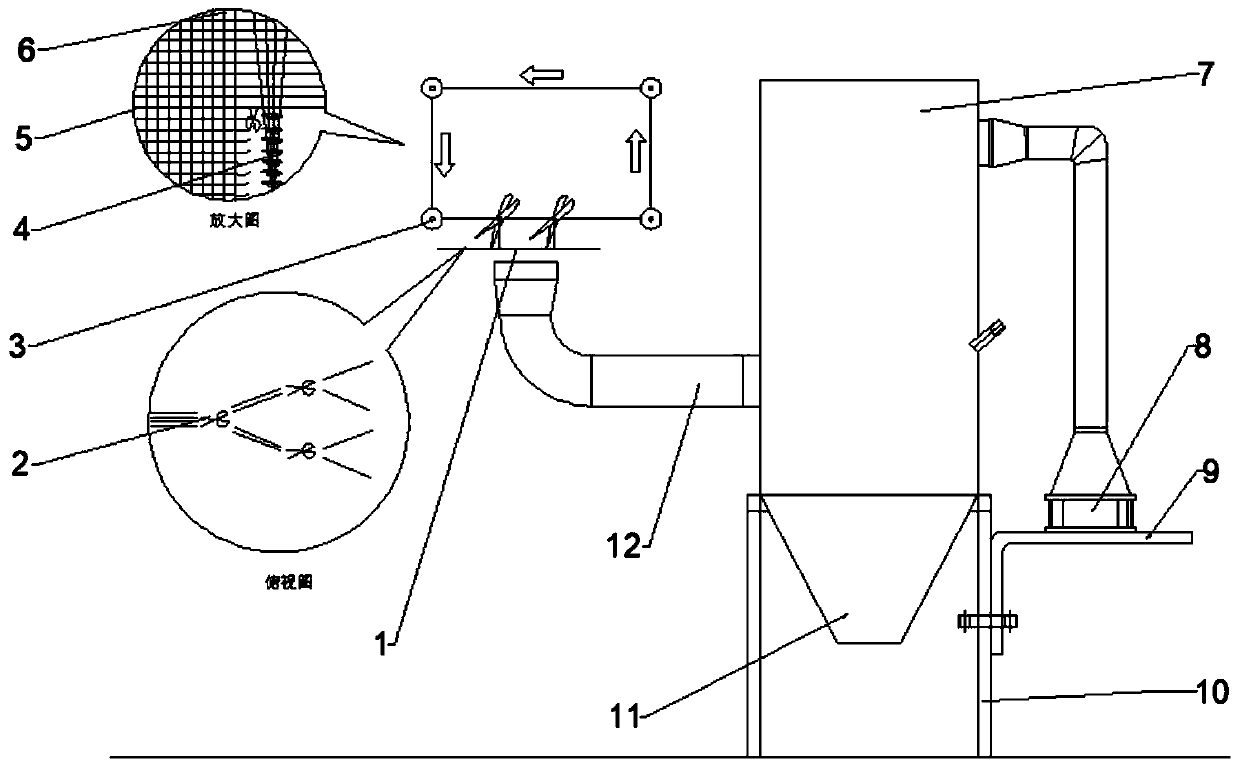

[0040] Such as figure 1As shown, the present invention is applicable to the waste weft thread end settlement collection device of loom, including lead wire separation assembly, lead wire guide assembly, thread end settlement collection assembly, thread end discharge assembly, power assembly and its accessories.

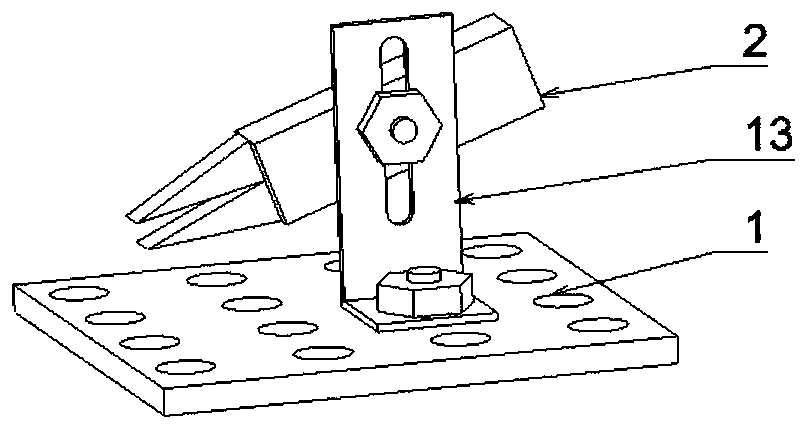

[0041] lead separation assembly such as figure 1 as shown in figure 2 It is a schematic diagram of the installation of the electric scissors 2. It includes an electric scissors base 1 with multiple mounting holes, an electric scissors 2, a guide wheel 3, and an electric scissors bracket 13. In order to separate the four warp yarn leads in adjacent positions, the three electric scissors 2 are distributed in a triangle, and are respectively fixed on the electric scissors bracket 13 by bolts. In order to prevent the bolts from loosen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com