Water-based ink composition, water-based ink resin and preparation method and application thereof

A technology of water-based ink and composition, which is applied in application, ink, household utensils, etc. It can solve the problems that water-based ink cannot meet the requirements of boiling resistance and cooking resistance, and achieve the effect of improving adhesion fastness, boiling resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

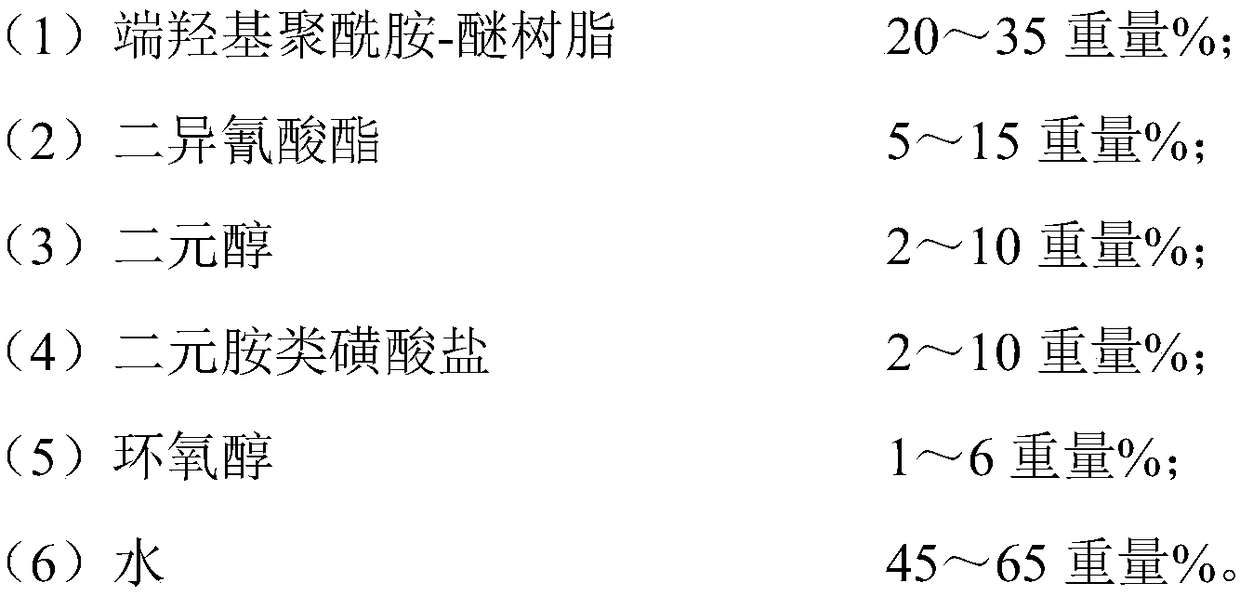

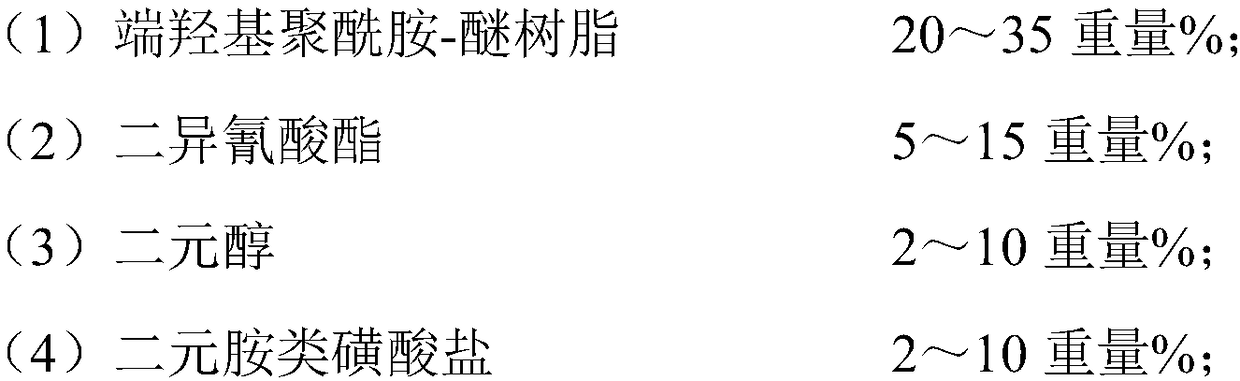

[0050] (1) 15kg hydroxyl-terminated polyamide-polyoxyethylene glycol resin (hydroxyl value 32mg (KOH) / g), 6kg hydroxyl-terminated polyamide-tetrahydrofuran-propylene oxide copolymerized glycol resin (hydroxyl value 36mg (KOH) / g) and 13kg of toluene diisocyanate were added to Reactor I, heated to 80°C for 2 hours, and then 7kg of 2,2-dimethyl-1,3-propanediol was added to react for 1.2 hours. The viscosity of the reactant, add 10kg of 2-(2-amino-cyclohexylamino)-sodium ethanesulfonate, stir at room temperature for 0.6 hours, heat up to 60°C, add 4kg of glycidyl alcohol and react for 1.8 hours to obtain a polymer .

[0051] (2) Add 45 kg of water to the reaction kettle II, pour the polymer in the reaction kettle I into the reaction kettle II under stirring, continue to stir and disperse at room temperature for 0.5 hours, remove acetone by vacuuming, and obtain the water-based ink resin.

Embodiment 2

[0053] (1) 27.5kg hydroxyl-terminated polyamide-polyoxypropylene diol resin (hydroxyl value 40mg (KOH) / g), 4kg diphenylmethane diisocyanate and 6kg dicyclohexylmethane diisocyanate are added in the reactor I, After heating to 90°C and reacting for 1.4 hours, add 2kg of 2-ethyl-2-butyl-1,3-propanediol to react for 1 hour, cool down to room temperature and add an appropriate amount of acetone to reduce the viscosity of the reactant, add 7kg of 2-[ (5-amino-1,3,3-trimethyl-cyclohexylmethyl)-amino]-sodium ethanesulfonate, stirred at room temperature for 0.75 hours, raised the temperature to 65°C, added 3.5kg epoxybutanol and reacted for 1.4 hours Polymers are then produced.

[0054] (2) Add 50 kg of water to the reaction kettle II, pour the polymer in the reaction kettle I into the reaction kettle II under stirring, continue to stir and disperse at room temperature for 0.6 hours, and remove acetone by vacuuming to obtain a water-based ink resin.

Embodiment 3

[0056] (1) Add 35kg of hydroxyl-terminated polyamide-polytetrahydrofuran diol resin (hydroxyl value 28mg (KOH) / g) and 5.5kg of hexamethylene diisocyanate into reactor I, heat to 100°C, and react for 1.8 hours , add 2kg of neopentyl glycol, 4kg of 2,4-dimethyl-1,5-pentanediol to react for 1.4 hours, drop to room temperature and add an appropriate amount of acetone to reduce the viscosity of the reactant, add 2kg of 2-[4-( 4-amino-cyclohexylmethyl)-cyclohexylamino]-sodium ethanesulfonate, stirred at room temperature for 1 hour, raised the temperature to 70°C, added 6 kg of glycidyl alcohol and reacted for 2 hours to obtain a polymer.

[0057] (2) Add 45.5kg of water to the reaction kettle II, pour the polymer in the reaction kettle I into the reaction kettle II under stirring, continue to stir and disperse for 0.75 hours at room temperature, and remove the acetone by vacuuming to obtain a water-based ink resin .

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com