Production device for sectional material fixed-length cutting, conveying and slag removal treatment

A production device and cutting device technology, which is applied in the direction of shearing devices, shearing machine accessories, maintenance and safety accessories, etc., can solve the problems of component damage, unfavorable automatic production, etc., and achieve high cutting accuracy and facilitate subsequent automated production , not easy to damage the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

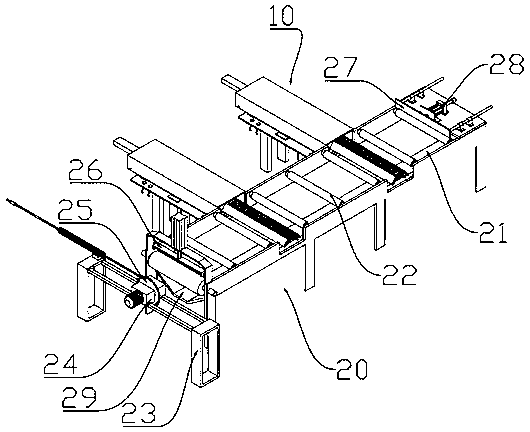

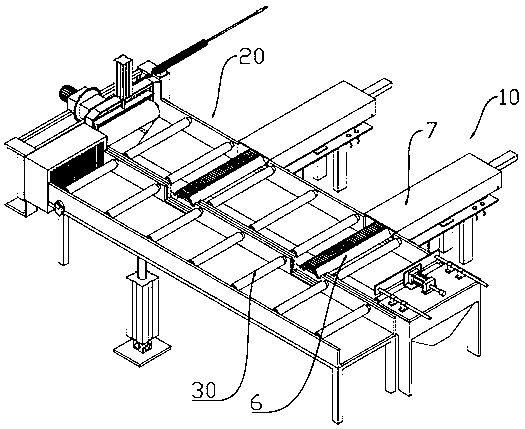

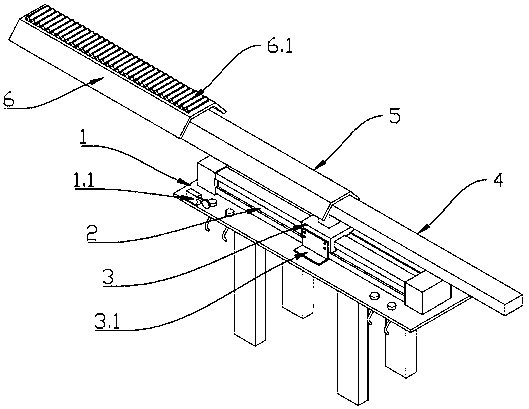

[0025] Such as Figure 1-7 As shown, the production device for profile fixed-length cutting, conveying, and slag removal treatment includes a fixed-length cutting platform 20 and a dumping slag suction platform 30 arranged in parallel, and the other side of the fixed-length cutting platform 20 is also provided. There are two sets of conveying units 10 for transferring the finished profiles cut on the cut-to-length platform 20 to the dumping and slag suction platform 30 .

[0026] The fixed-length cutting platform 20 includes a support bracket 21 and a profile conveying roller 22 erected on the support bracket 21. The front end of the support bracket 21 is provided with a cutting device, and the cutting device includes a frame 23 and is arranged on the frame. The guide rail, on the guide rail, is provided with a moving slider 24 driven by an air cylinder, on the moving slider 24, a cutting tool 25 is fixedly installed, and above one end of the support bracket 21 close to the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com