Constant-power driving power supply based on ARM and multiplier and driving method

A driving power supply and constant power technology, applied in the field of constant power ultrasonic driving power supply, can solve the problems of increasing the heat generation of the driving circuit, tuning and matching circuit errors, low system power factor, etc., to achieve digital frequency control, ensure accuracy, and improve identification The effect of phase accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

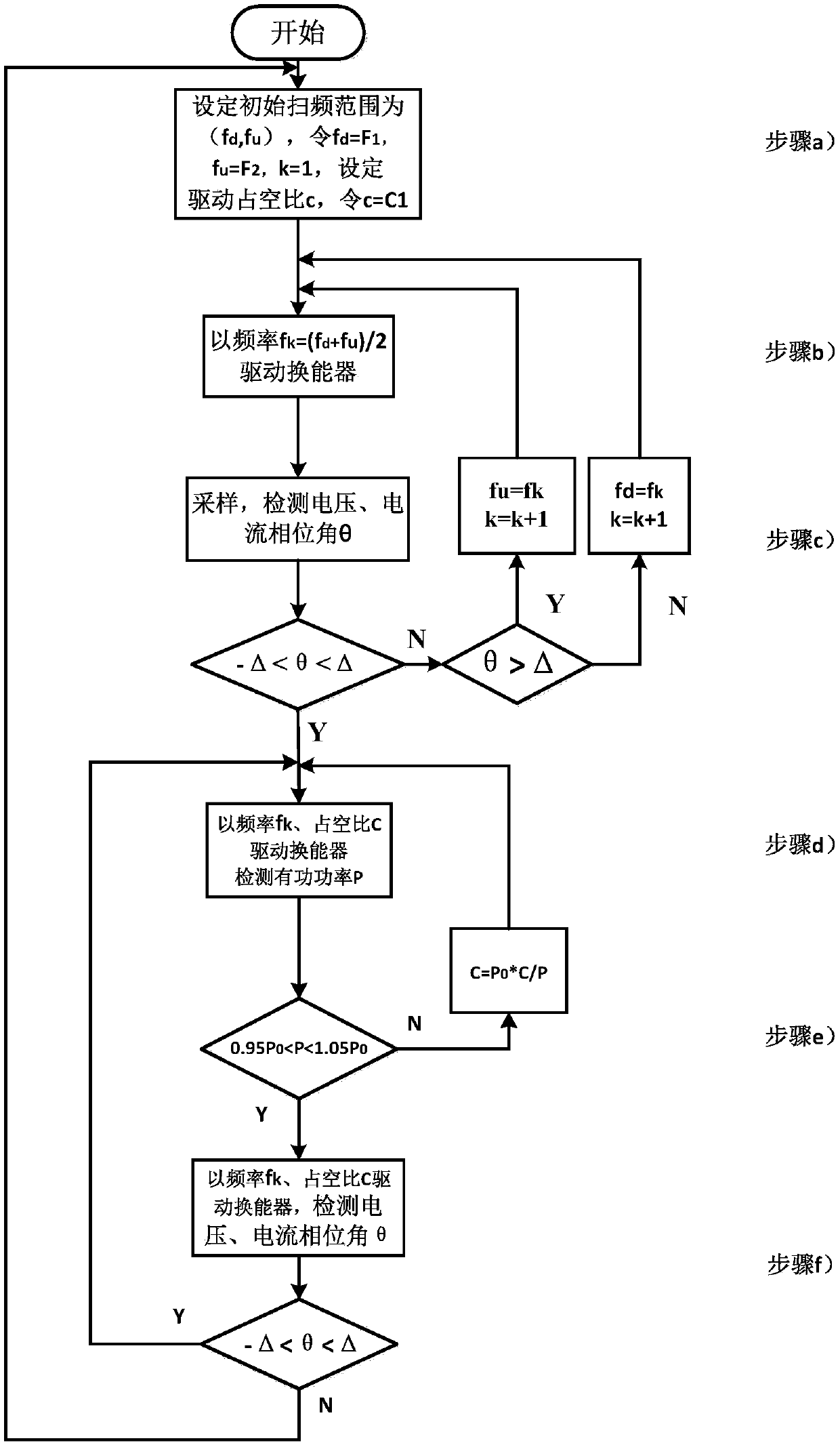

Method used

Image

Examples

Embodiment Construction

[0050] The technical scheme that the present invention adopts is, a kind of constant power drive power supply based on ARM and multiplier, comprises following four parts:

[0051] The first part is the drive circuit, such as figure 1 As shown, it consists of a DDS (Direct Digital Synthesizer) chip 18, an integrated PWM (Pulse Width Modulation) wave control chip 6 (such as SG3525A) and an inverter amplifier circuit 5. The ARM microprocessor outputs two DA (Digital to Analog Convert ) signal controls the oscillation frequency and duty cycle of the integrated PWM wave control chip oscillator, and the ARM microprocessor controls the DDS chip to output a square wave of any frequency to the synchronous end of the integrated PWM wave control chip, precisely controlling the frequency of the output PWM wave, so as to realize the drive Synchronous and precise control of the frequency of the PWM square wave. The PWM square wave is driven to output to the inverter amplifier circuit 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com