Lithium-sulfur battery material based on waste cigarette end biomass resources and preparation method thereof

A biomass resource and lithium-sulfur battery technology, applied in the fields of materials and energy, can solve the problems of cumbersome preparation process, high cost, and low sulfur loading capacity, and achieve the effect of simple preparation process, low cost, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1, the preparation method and application of lithium-sulfur battery materials derived from biomass resources such as waste cigarette butts, including the following steps:

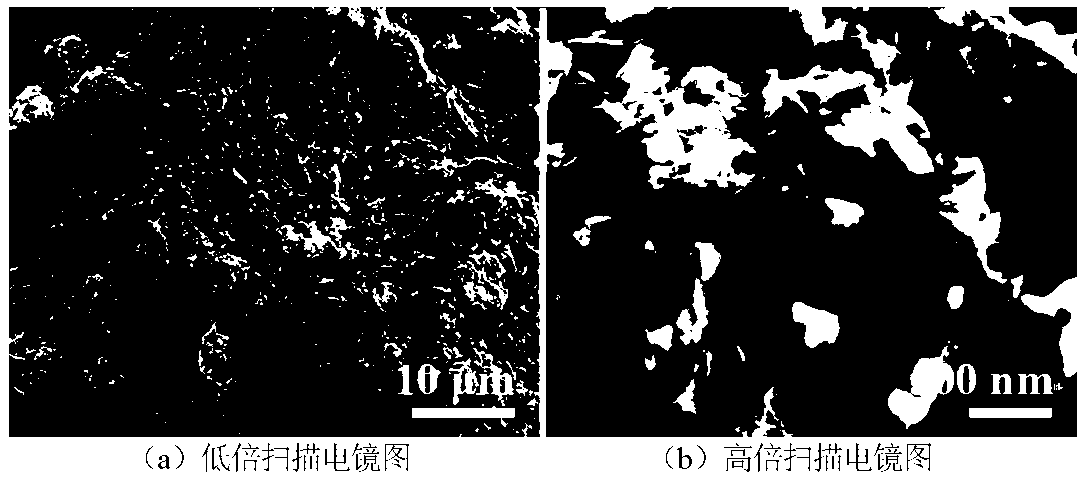

[0020] (1) Pretreatment of raw materials: The collected Marlboro cigarette butts (mainly composed of cellulose diacetate) were ultrasonically washed 3 to 5 times with 95% ethanol and water, and dried in a constant temperature drying oven at 60°C After drying for 2-24 hours, the resulting product is biomass carbon material (BC);

[0021] (2) Preparation of composite graphene-based biomass carbon material (GO / BC): mix 3-10 mg / mL graphene oxide and 10.0 mg biomass-based carbon material (BC), stir thoroughly for 2-8 h, then take out the composite The final sample was placed in a freeze dryer at -50 °C and freeze-dried for 24–36 h, and the resulting product was the composite precursor of biomass porous carbon (BC) and graphene (GO / BC);

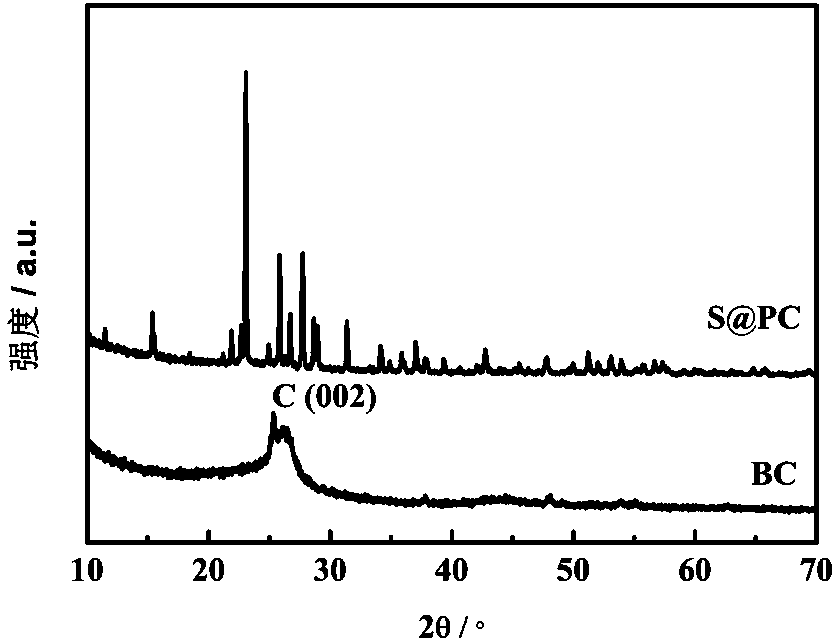

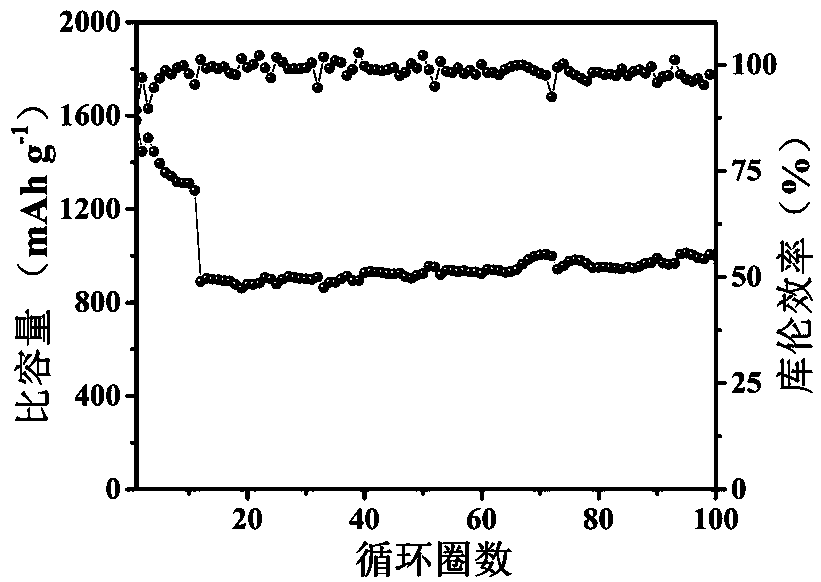

[0022] (3) In situ construction of S@GO / PC composites using...

Embodiment 2

[0025] Embodiment 2, the preparation method and application of lithium-sulfur battery materials derived from biomass resources such as waste cigarette butts, includes the following steps:

[0026] (1) Pretreatment of raw materials: The collected Liqun brand cigarette butts (mainly composed of cellulose diacetate) were ultrasonically washed 3 to 5 times with 95% ethanol and water, and dried in a constant temperature drying oven at 60°C. Drying for 2-24 hours, the resulting product is biomass carbon material (BC);

[0027](2) Preparation of composite graphene-based biomass carbon material (GO / BC): mix 3-10 mg / mL graphene oxide and 10.0 mg biomass-based carbon material (BC), stir thoroughly for 2-8 h, then take out the composite The final sample was placed in a freeze dryer at -50 °C and freeze-dried for 24–36 h, and the resulting product was the composite precursor of biomass porous carbon (BC) and graphene (GO / BC);

[0028] (3) In situ construction of S@GO / PC composites using ...

Embodiment 3

[0031] Embodiment 3, the preparation method and application of lithium-sulfur battery materials derived from biomass resources such as waste cigarette butts, includes the following steps:

[0032] (1) Pretreatment of raw materials: The collected Marlboro cigarette butts (mainly composed of cellulose diacetate) were ultrasonically washed 3 to 5 times with 95% ethanol and water, and dried in a constant temperature drying oven at 60°C for 12 days. h, the resulting product is a biomass carbon material (BC);

[0033] (2) Biomass carbon material (GO / BC) for preparing composite graphene: 10 mg / mL graphene oxide and 1-20 mg biomass carbon material (BC) were mixed thoroughly for 2-8 h, and then the composite was taken out. The final sample was placed in a freeze dryer at -50 °C and freeze-dried for 24–36 h, and the resulting product was the composite precursor of biomass porous carbon (BC) and graphene (GO / BC);

[0034] (3) In situ construction of S@GO / PC composites using GO / BC precur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com