Method for extracting fault signal feature of mechanical device

A technology of mechanical equipment and fault signals, applied in the field of intelligent systems, can solve problems such as lack of versatility, and achieve the effect of correctness guarantee and high recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

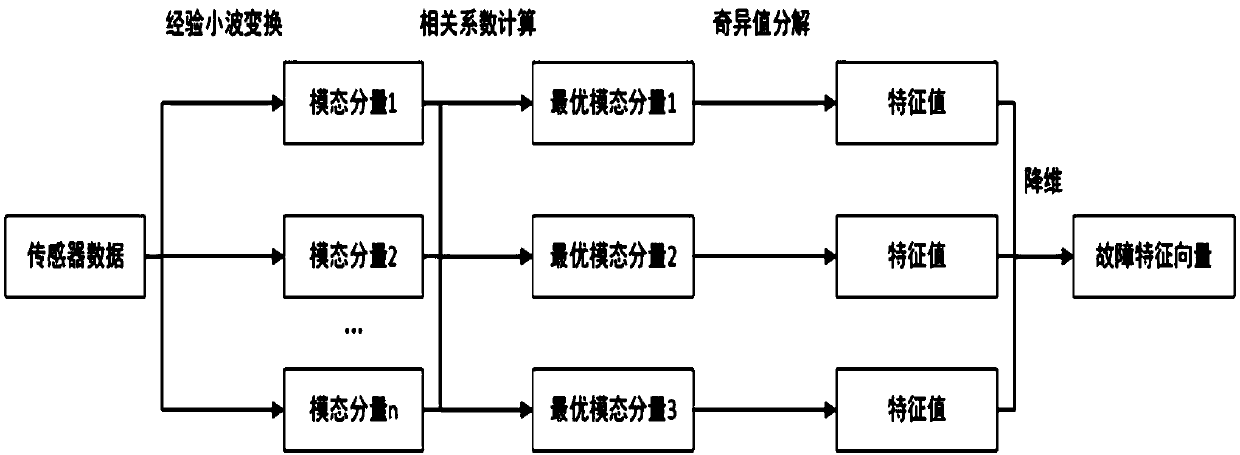

[0036] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] This embodiment takes the bearings commonly used in the production of automobile assembly lines as an example to illustrate the method for extracting features of mechanical equipment fault signals of the present invention, such as figure 1 As shown, the steps are as follows.

[0038] Step 1. Data collection: use the vibration sensor to collect the vibration signal of the bearing, the sampling frequency is 1024kHz, and each sample has 1024 points;

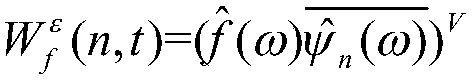

[0039] Step 2, empirical wavelet transform: carry out empirical wavelet transform to the collected vibration signal, obtain several modal components of signal decomposition;

[0040] Step 3, select the optimal modal component: calculate the correlation coefficient between each modal component and the original vibration signal, and select the 3 optimal modal components with the highest cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com