Method and system for optimizing connection speed of continuous miniature straight segments

An optimization method and connection speed technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as poor processing quality and equipment vibration in continuous micro-line segments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

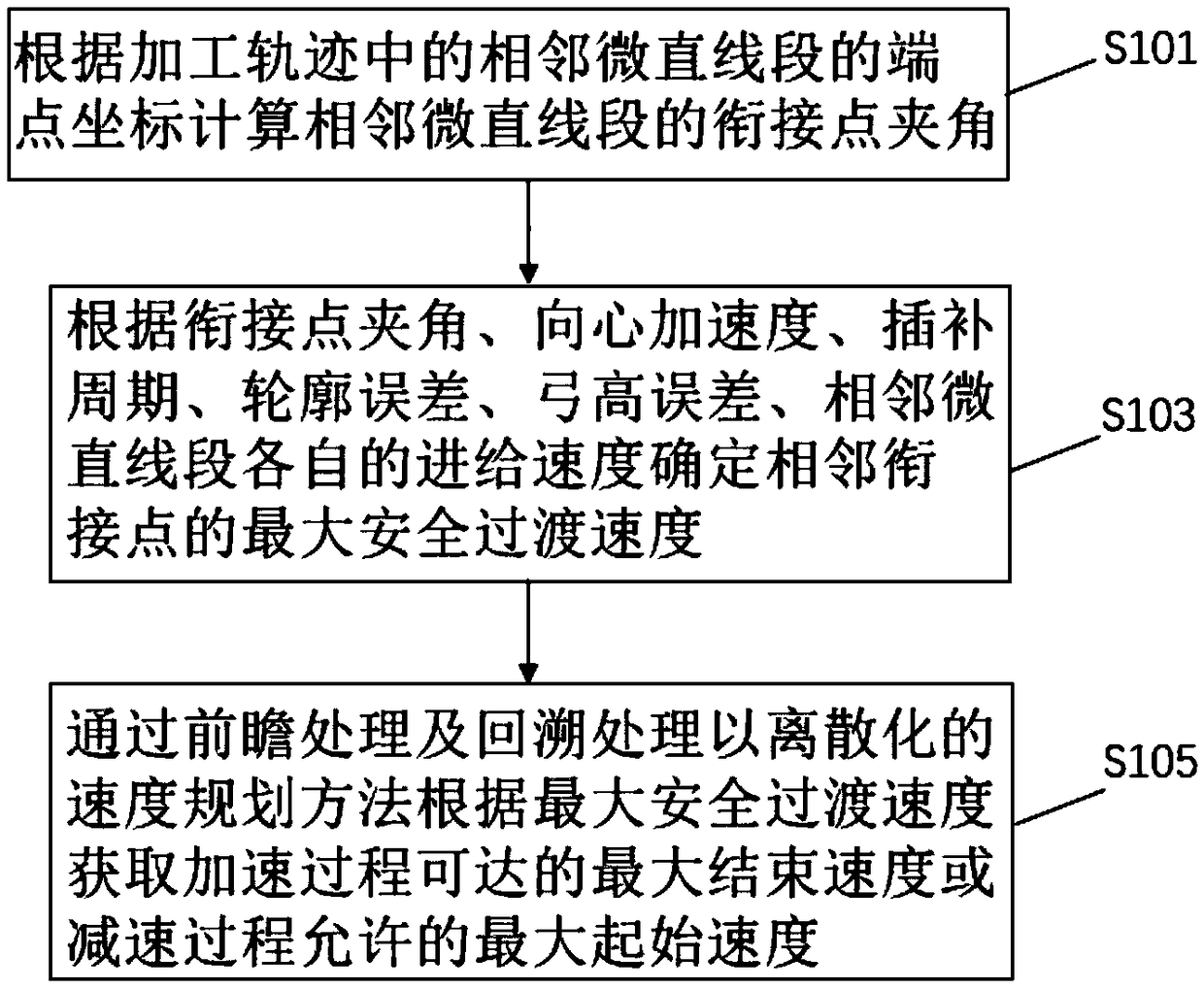

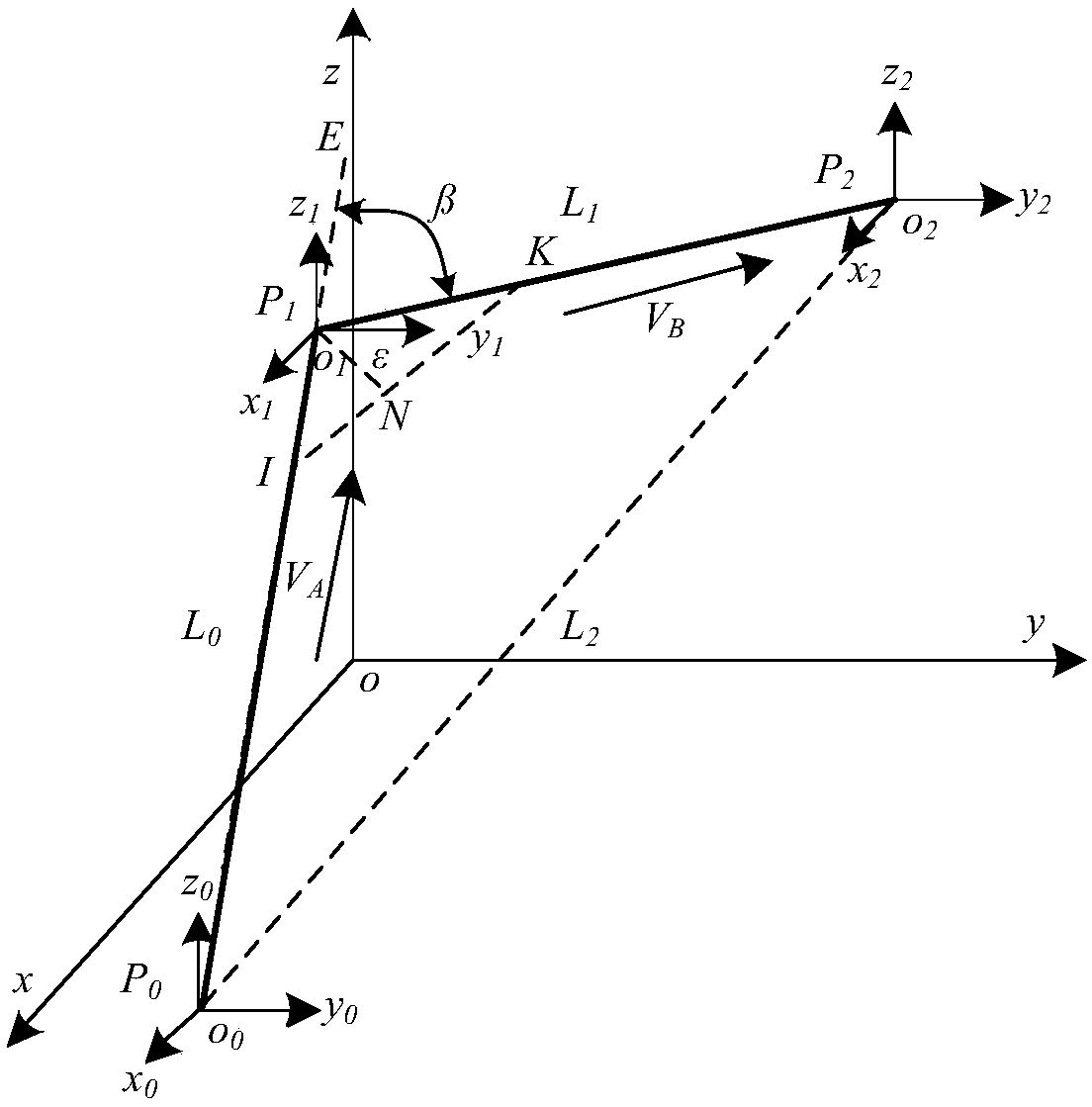

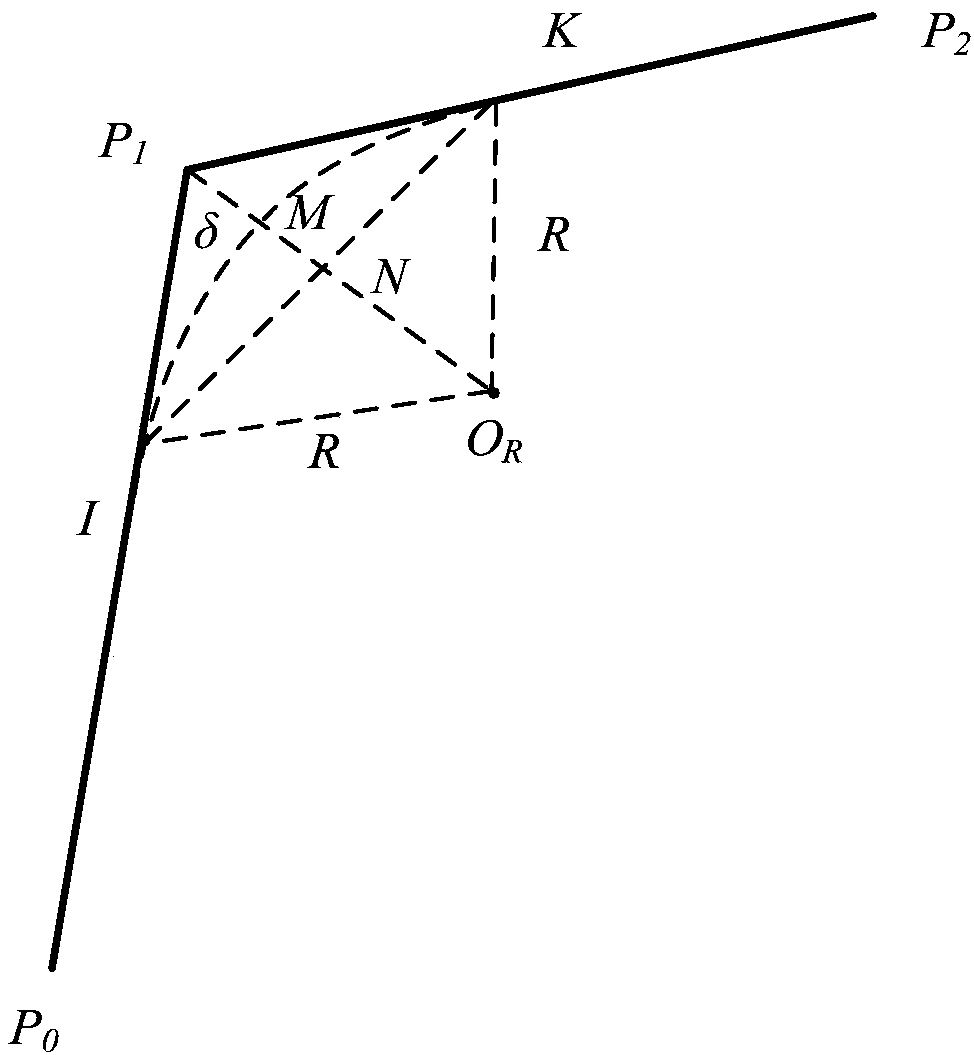

[0085] Please refer to figure 1 , Figure 1a and Figure 1b , figure 1 It is a flow chart of the method for optimizing the joint speed of continuous micro-straight line segments (hereinafter referred to as "optimization method") in Embodiment 1 of the present invention. Figure 1a It is a schematic diagram of the angle between the joint points of adjacent micro-line segments in Embodiment 1 of the present invention. Figure 1b It is a schematic diagram of the arc transition radius of the adjacent micro-straight line segments in Embodiment 1 of the present invention. Optimization methods include:

[0086] S101. Calculate the included angle of the connection point of the adjacent micro-line segments according to the end point coordinates of the adjacent micro-line segments in the machining trajectory.

[0087] exist Figure 1a , the adjacent micro-line segment P 0 P 1 and P 1 P 2 Intersect at point P1, and the coordinates of the endpoints are P 0 (x 0 ,y 0 ,z 0 ), ...

Embodiment 2

[0112] Please refer to figure 2 , figure 2 It is a flow chart of the method for optimizing the joint speed of continuous micro-straight line segments (hereinafter referred to as "optimization method") in Embodiment 2 of the present invention. Optimization methods include:

[0113] S105a, perform look-ahead initialization;

[0114] Forward initialization includes:

[0115] Set the number of forward-looking segments N and the starting speed V of the i-th segment i,s , the end velocity V of the i-th segment i,e and the displacement L of the i segment i ;

[0116] According to the initial velocity V of the i-th segment i,s , the end velocity V of the i-th segment i,e and the acceleration A of the i segment i Calculate the starting velocity V from segment i i,s to the end speed V of the i segment i,e The number of cycles n of the i-th segment required i :

[0117]

[0118] According to the cycle number n of the i-th segment i Get the actual acceleration A of the ...

Embodiment 3

[0168] Please refer to image 3 , image 3 It is a block diagram of the optimization system (hereinafter referred to as "optimization system") of the joint speed of continuous micro-straight line segments according to Embodiment 3 of the present invention. The optimization system 300 is applied to numerical control machining. Optimization system 300 includes:

[0169] Calculation module 310, the calculation module 310 calculates the angle between the joint points of adjacent micro-line segments according to the endpoint coordinates of adjacent micro-line segments in the processing trajectory;

[0170] Determination module 320, the determination module 320 determines the maximum safe transition speed of adjacent joint points according to the angle between joint points, centripetal acceleration, interpolation period, contour error, bow height error, and the respective feed speeds of adjacent micro-line segments;

[0171] Acquisition module 330, the acquisition module 330 obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com