High-airtightness tunnel kiln

A tunnel kiln and high-density technology, applied in the field of tunnel kiln, can solve the problems of increasing airflow resistance, thermal deformation of skirts, difficult to control the quality of fired products, etc., and achieve the effect of good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

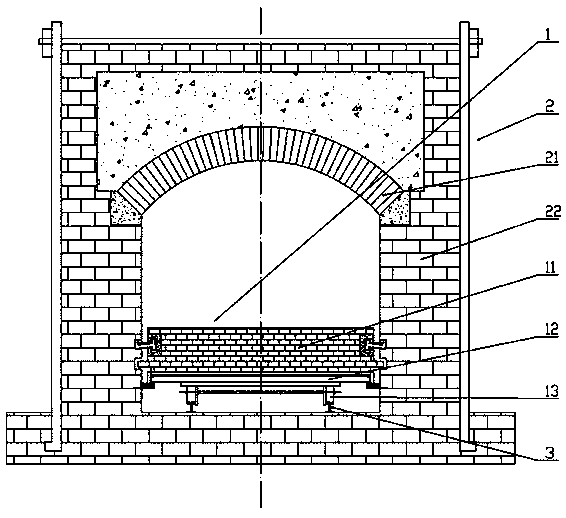

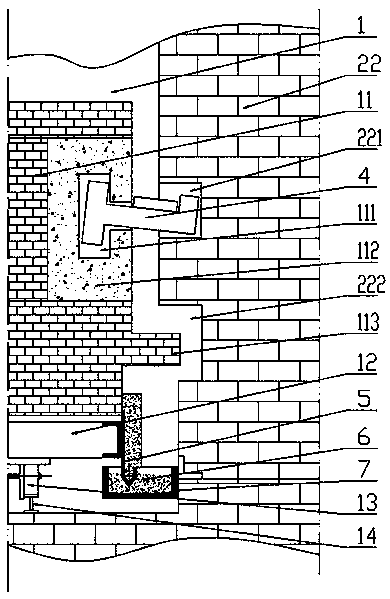

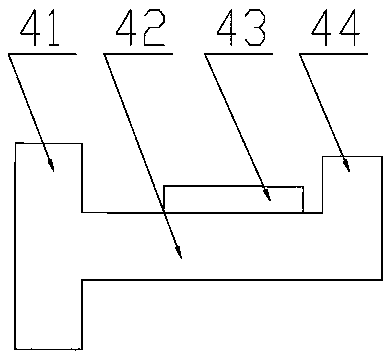

[0028] exist figure 1 In the shown high-sealed tunnel kiln, the kiln wall 22 and the kiln roof 21 constitute the kiln body 2 of the tunnel kiln, kiln rails 3 are laid on the bottom surface of the tunnel kiln, and the kiln car 1 is located between the kiln walls 22 on both sides and runs in the kiln. On the rail 3, the kiln car 1 includes a car frame 12, a wheel 13 rotatably supported on the car frame 12 and located on the kiln rail 3, and a kiln car lining 11 located on the car frame 12. see figure 2 The kiln car lining part 11 is built on the upper surface of the car frame 12 by refractory bricks. The refractory bricks located on both sides of the kiln car lining part 11 include T-shaped groove bricks 112, and several T-shaped groove bricks 112 are along the kiln car lining. T-shaped grooves 111 are arranged in the T-shaped groove bricks 112. In this way, T-shaped grooves 111 are formed on the side of the kiln car lining part 11, and the T-shaped grooves 111 extend from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com