Tube slot backfilling structure for existing road and construction method thereof

A construction method and pavement structure technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of pipeline cracking, sand leakage, insufficient compaction, etc., and achieve the effect of simple structure and good driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

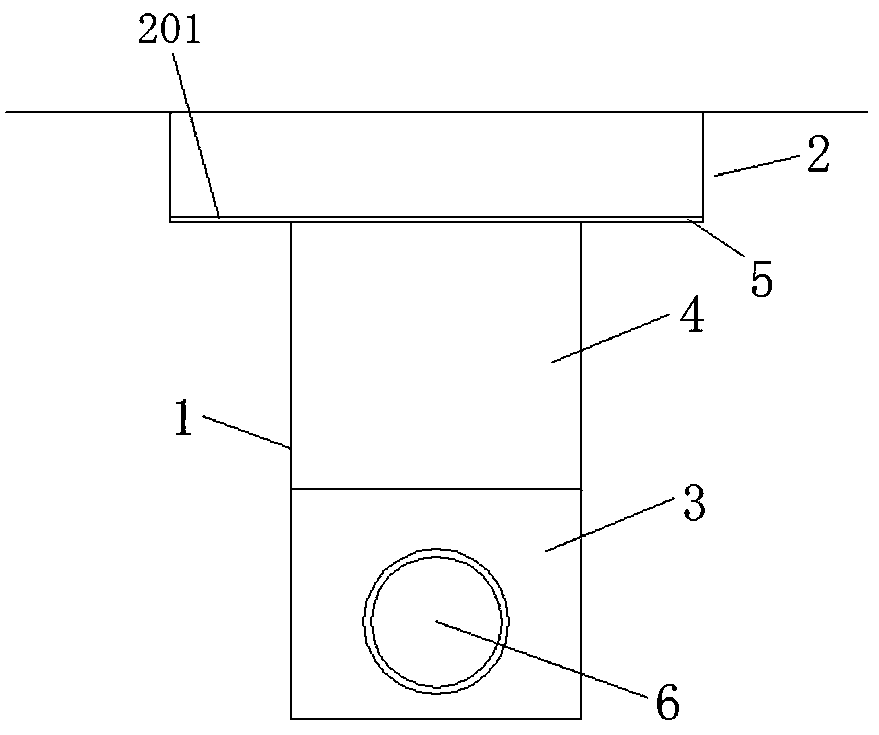

[0025] Such as figure 1 As shown, the present invention is an existing road pipe groove backfill structure, including a pipe groove 1 and a pavement structure layer 2 laid on the upper side of the pipe groove 1, and the pipe groove 1 is sequentially backfilled with the first filler layer from bottom to top 3 and the second packing layer 4, the first packing layer 3 is foamed concrete or domestic waste incineration slag mixture; the second backfill layer 4 is domestic waste incineration slag mixture; the bottom surface of the base layer of the pavement structure layer 2 A geogrid 5 is laid at 201 , and the geogrid 5 is in contact with the top surface of the second packing layer 4 . By setting two layers of filler and geogrid, the overall structural strength can be made high, and the gelation characteristics of domestic waste incinerat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com