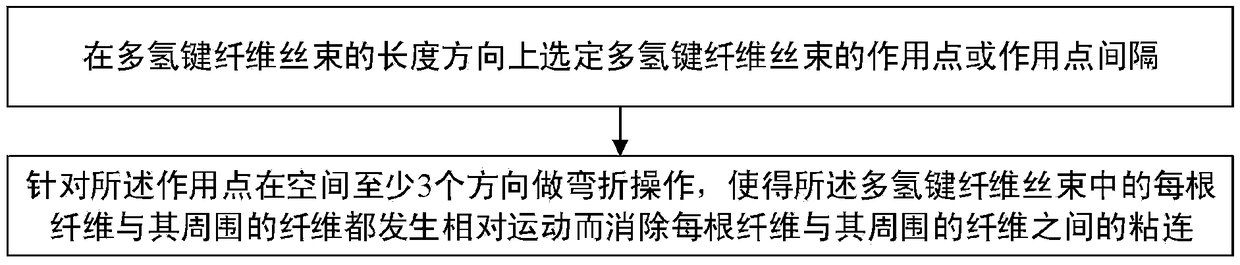

Method for opening multi-hydrogen bond fiber tow

A fiber tow and hydrogen bond technology, which is applied in the field of opening multi-hydrogen bond fiber tow, can solve the problems of increasing production costs and restricting fiber applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

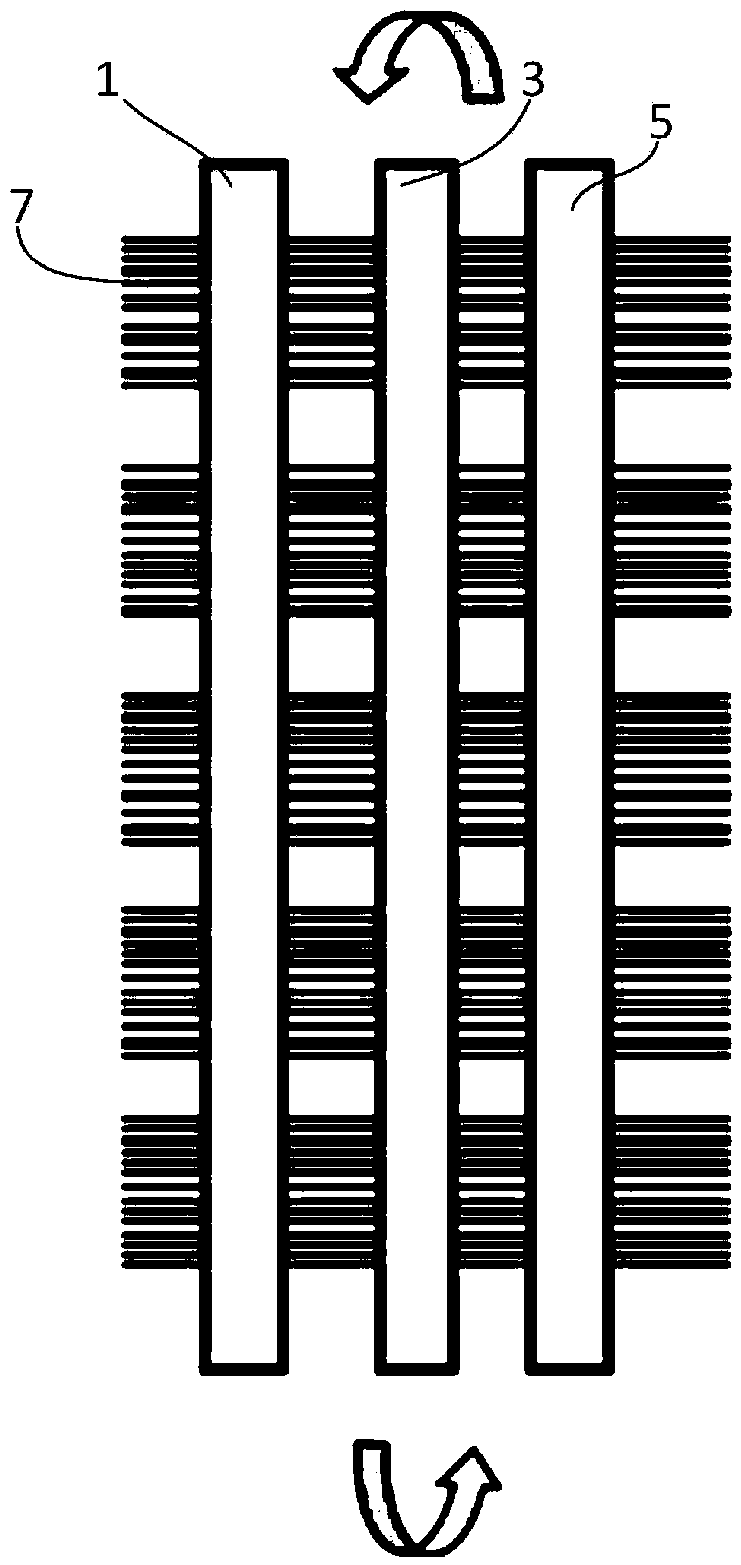

Embodiment 1

[0062] Set the distance between the action disk of the opening device and the feeding disk and silk outlet disk to be 1cm, the diameter of the feeding hole, action hole, and silk outlet hole to be 5mm, and take 50000dtex seaweed fiber tow, the tow is dried In the unopened state, it has the characteristics of obvious adhesion and stiffness. After passing through the feeding roller, the tow passes through the feeding hole, action hole and silk outlet hole of the device in sequence, and is pulled out by the drafting roller to keep the fiber When the tension is 200g, turn on the tow traction device to keep the tow moving forward at a speed of 10m / min, then start the opening device, and the action disc rotates periodically along a circular track with a diameter of 2cm at a speed of 40 rpm, and the tow After passing through the opening device in sequence, it becomes soft, the adhesion and induration before opening are basically eliminated, and the fibers are well opened.

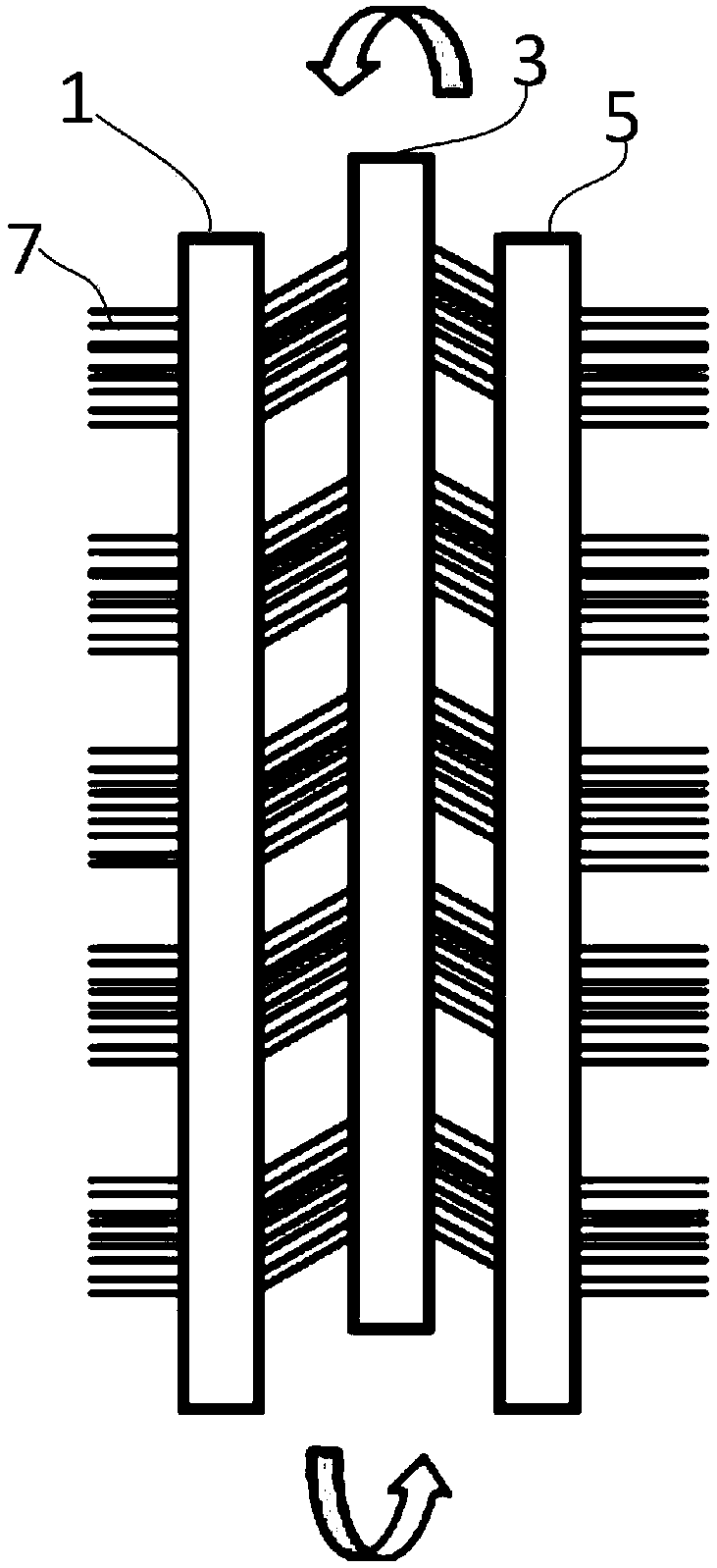

Embodiment 2

[0064] Adopt an opening device that is arranged in series by two sets of feeding discs, action discs, and silk output discs. Set the distance between the action disc, the feeding disc, and the output disc at 1 cm, and set the holes for the feeding holes, action holes, and output holes. The diameter is 1cm, and the regenerated cellulose fiber tow of 100000dtex is taken. The tow is in an unopened state after drying, and has obvious characteristics of sticking and hardening. The tow passes through the feeding roller and then passes through the feeding device in sequence The entry hole, action hole, and thread exit hole are pulled out by the drafting roller. Keep the fiber tension at 1000g. Turn on the tow pulling device to keep the tow moving forward at a speed of 30m / min. Then start the opening device to move The disc oscillates periodically along a circular trajectory with a diameter of 5cm at a speed of 60 rpm. The tow becomes soft after passing through the opening device in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com