Compound enzyme preparation for reducing TSNAs (tobacco-specific nitrosamines) as well as preparation method and application of compound enzyme preparation

A compound enzyme preparation and nitrosamine technology, which is applied in the field of tobacco leaf processing, can solve the problems of high preparation cost of microbial inoculants, restricting large-scale popularization and application, and large influence of environmental conditions, so as to reduce the content of TSNAs and facilitate large-scale popularization. Apply and improve the effect of quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

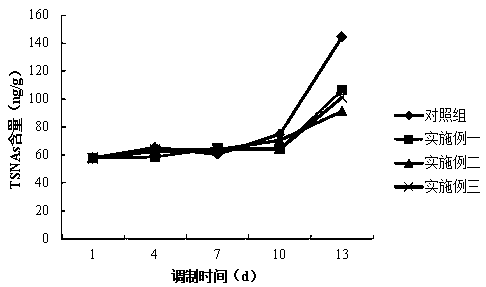

Examples

Embodiment 1

[0027] The compound enzyme preparation for reducing tobacco leaf-specific nitrosamines in this embodiment is composed of the following components by mass percentage: 0.03% neutral protease, 0.02% pectinase, 0.01% xylanase, 0.02% glucoamylase, β- Glucanase 0.01%, sterile distilled water 99.91%.

[0028] The preparation method of the above-mentioned compound enzyme preparation that present embodiment relates to, comprises the steps:

[0029] (1) Prepare raw materials according to the above components;

[0030] (2) Stir and mix the components of step (1) and sterile distilled water according to the mass percentage, the stirring speed is 75rpm, the mixing temperature is 40°C, and the pH is 5.5, until the compound enzyme preparation suspension is uniformly obtained, that is Compound enzyme preparation.

[0031] The application of the above-mentioned compound enzyme preparation involved in this embodiment in the preparation of sun-cured tobacco includes the following steps:

[00...

Embodiment 2

[0039] The compound enzyme preparation for reducing tobacco leaf-specific nitrosamines in this embodiment is composed of the following components by mass percentage: 0.02% neutral protease, 0.01% pectinase, 0.005% xylanase, 0.01% glucoamylase, β- Glucanase 0.005%, α-amylase 0.01%, medium temperature amylase 0.02%, cellulase 0.02%, sterile distilled water 99.90%.

[0040] The preparation method of the above-mentioned compound enzyme preparation that present embodiment relates to, comprises the steps:

[0041] (1) Prepare raw materials according to the above components;

[0042] (2) Stir and mix the components of step (1) and sterile distilled water according to the mass percentage, the stirring speed is 50rpm, the mixing temperature is 35°C, and the pH is 5.2, until the compound enzyme preparation suspension is uniformly obtained, that is Compound enzyme preparation.

[0043] The application of the above-mentioned compound enzyme preparation involved in this embodiment in the...

Embodiment 3

[0049] The composite enzyme preparation for reducing tobacco leaf-specific nitrosamines of this embodiment consists of the following components in mass percentage:

[0050] Tobacco compound enzyme 0.5%, neutral protease 0.01%, pectinase 0.005%, xylanase 0.0025%, glucoamylase 0.005%, β-glucanase 0.0025%, α-amylase 0.005%, medium temperature amylase 0.005% %, cellulase 0.005%, neutral lipase 0.01% and sterile distilled water 99.45%.

[0051] The preparation method of the above-mentioned compound enzyme preparation that present embodiment relates to, comprises the steps:

[0052] (1) Prepare raw materials according to the above components;

[0053] (2) Stir and mix the components of step (1) and sterile distilled water according to the mass percentage, the stirring speed is 100rpm, the mixing temperature is 45°C, and the pH is 5.8, until the compound enzyme preparation suspension is uniformly obtained, that is Compound enzyme preparation.

[0054] The application of the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com