Aluminum ingot bundling machine

A stacker and aluminum ingot technology, which is applied in the field of aluminum ingot casting and subsequent related equipment, can solve the problems of low efficiency of manual stacking operation, personal injury of aluminum ingots, and difficult transportation of aluminum ingots, so as to improve the efficiency of bundling and facilitate transportation. , the effect of shortening the binding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

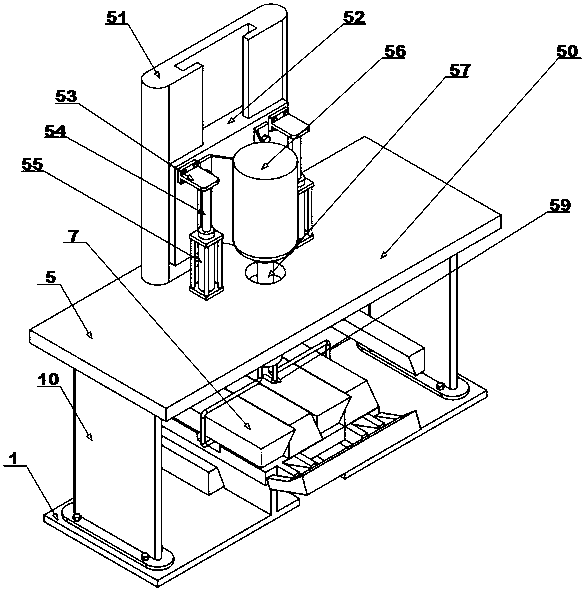

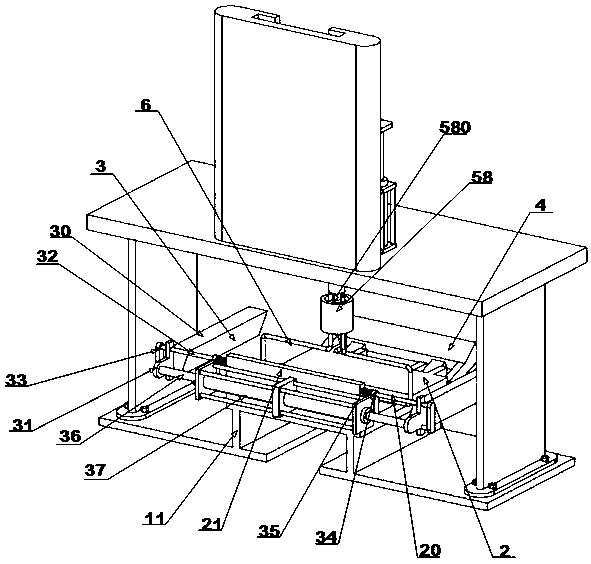

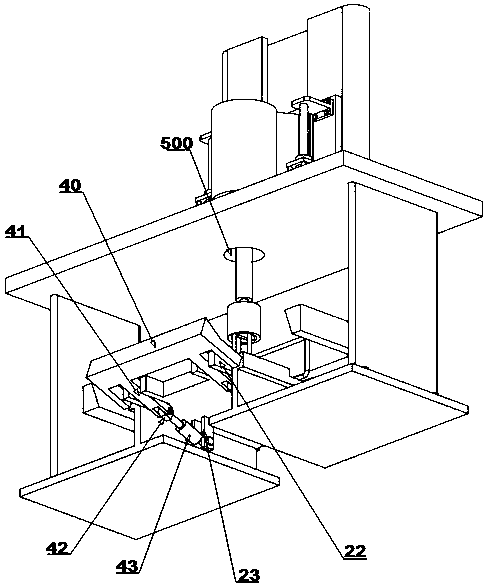

[0033] Such as Figure 1~Figure 3 As shown, an aluminum ingot stacking machine includes a base 1, a stacking platform 2, a side pressing mechanism 3, a forward pushing mechanism 4, and a binding mechanism 5. The stacking platform 2 is arranged on the base 1, and the side The pressing mechanism 3 is arranged on both sides of the binding platform 2, the forward pushing mechanism 4 is arranged at the front end of the binding platform 2, and the binding mechanism 5 is arranged above the base 1;

[0034] The number of the lateral pressure mechanism 3 is two;

[0035] Both sides of the upper surface of the base 1 are fixed with binding mechanism support plates 10, the binding mechanism 5 is arranged on the upper end of the binding mechanism support plate 10, and the inside of the binding mechanism support plate 10 is provided with a binding platform There are two supporting plates 11, the binding platform 2 is arranged on the upper end of the supporting plate 10 of the binding mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com