Improved battery

An improved, battery technology, applied in battery boxes/jackets, battery pack components, small-sized batteries/battery packs, etc., to achieve the effect of obvious heat dissipation, increase shell strength, and improve heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

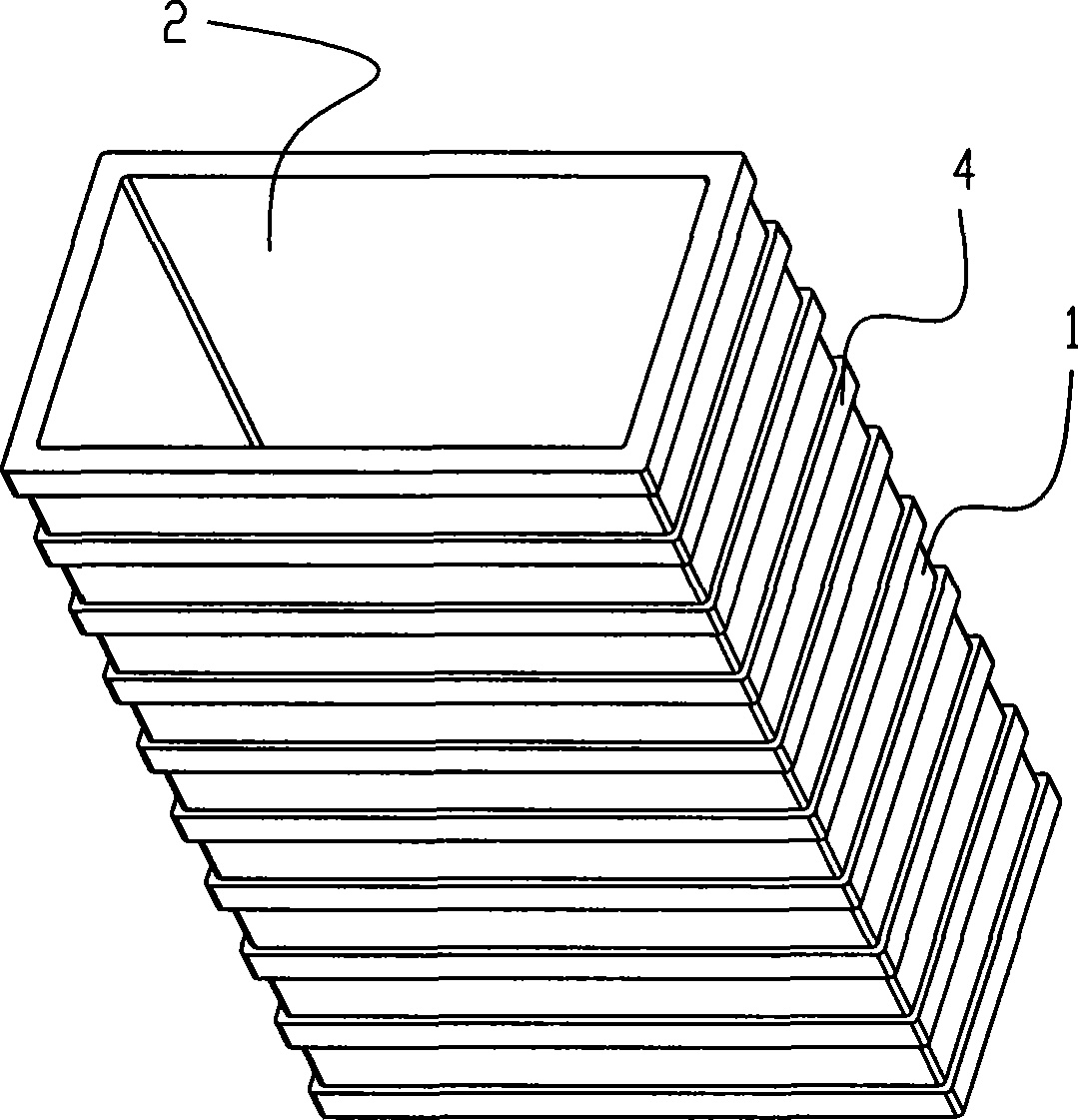

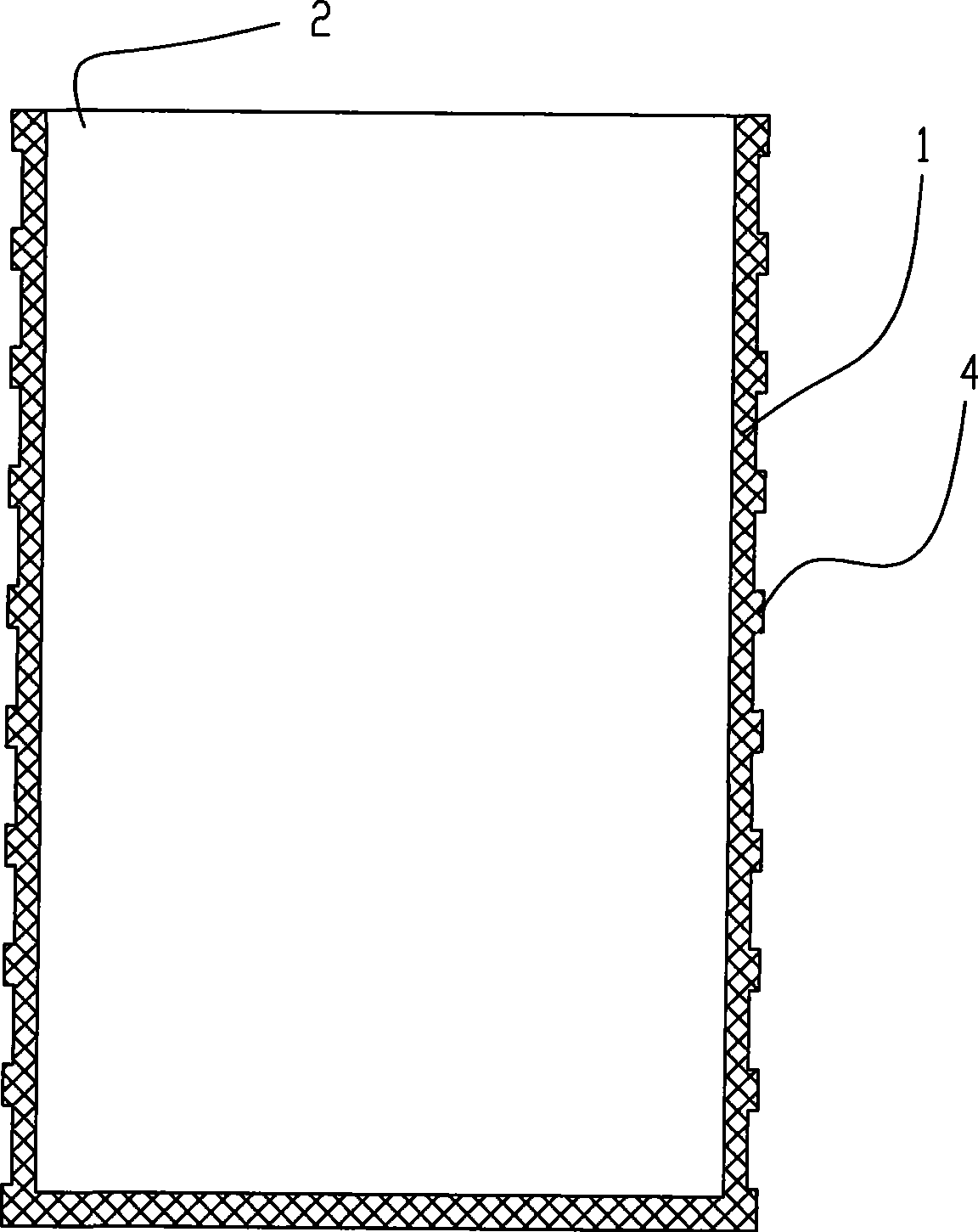

[0042] Embodiment one: if Figure 1-3 As shown, the battery of this embodiment includes a housing 1, an upper cover 3, a pole 6, a lithium battery and a conductive strip, the housing 1 is in the shape of a cuboid, and the opening of the housing is sealed by an upper cover 3; the upper cover 3 is embedded with a pole 6. The outer end of the pole 6 is connected to the conductive strip. The casing 1 has a built-in lithium battery, and the outer walls around the casing 1 form reinforcing ribs 4, the cross section of which is rectangular, that is, the reinforcing ribs 4 are horizontal bars. The reinforcing ribs 4 are parallel to the edge of the upper opening 2 of the housing, and are evenly arranged on the outer walls of the housing 1 in the transverse direction. The reinforcing ribs on the adjacent outer walls of the housing are connected, that is, the four reinforcing ribs on the same horizontal plane of the outer walls of the housing are connected in a circle. The horizontal r...

Embodiment 2

[0043] Embodiment two: if Figure 4-6 As shown, a liquid filling column 31 is formed upwards in the middle of the upper cover 3 , and a through hole 311 is formed inside the liquid adding column 31 , and the through hole 311 communicates with the inside of the battery case. Four arc-shaped annular grooves 32 are formed on the upper cover of the periphery of the liquid-filling column 31. The wall thickness of the arc-shaped annular grooves 32 is determined by the gas pressure that the battery can withstand. The four arc-shaped annular grooves 32 form a The circle surrounds the filling column 31. During the use of the battery, after a certain amount of gas is generated inside and reaches the specified pressure, the arc-shaped ring groove 32 will be broken by the internal air pressure, and the part surrounded by four arc-shaped ring grooves 32 will act as a safety valve for the battery. Function, through this part, the gas generated inside the casing is discharged in time, avoid...

Embodiment 3

[0048] Embodiment three: as Figure 7-11 As shown, when the upper cover 3 is molded, the battery pole 6 is molded into it at the same time, so that the upper cover 3 and the battery pole 6 are connected into one body without additional assembly. In this way, the tightness between the pole and the upper cover is enhanced, and there is no need to use additional O-rings to strengthen the tightness between the pole and the cover. In addition, it enhances the overall manufacturability of the battery, reduces procedures, saves costs, and enhances the conductivity of the entire battery pole surface.

[0049] The upper cylinder 331 of the battery pole 6 extends out of the upper cover 3 , and the lower part of the battery pole 6 is provided with two holes 332 . A screw hole is formed in the middle part of the upper section of the battery pole 6, and the rivet 7 extends into the screw hole after passing through the conductive strip 5, and the conductive strip 5 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com