Main rotor mechanism of single-rotor unmanned aerial vehicle

A main rotor and unmanned aerial vehicle technology, applied in the field of unmanned aerial vehicles, can solve the problems that the deflection cannot reach a predetermined angle, the deflection and rotation setting value error, the main rotor cannot be successfully completed, etc., so as to avoid axial creep and improve the The effect of precision and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

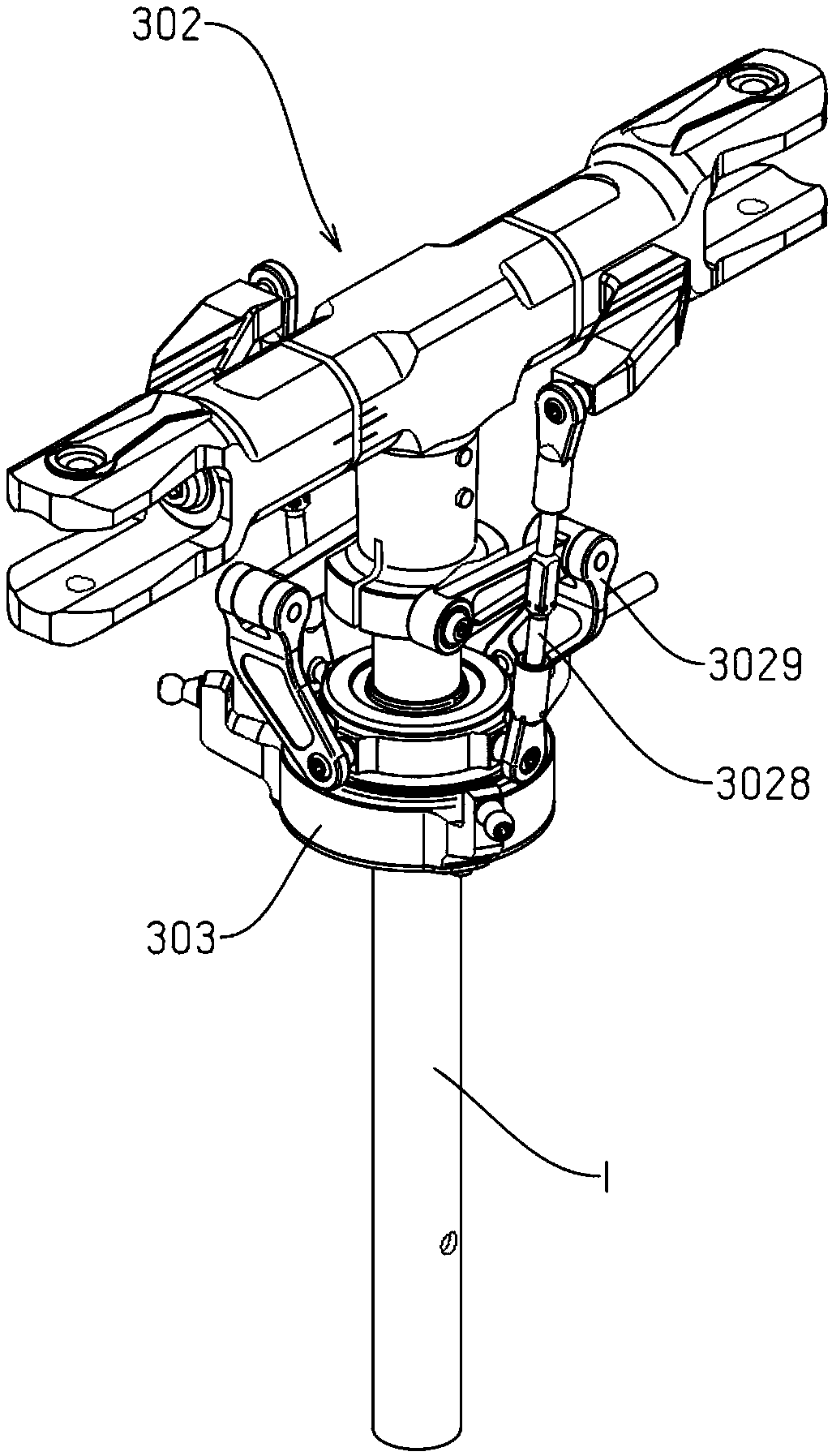

[0038] Embodiment: the main rotor mechanism of a kind of single-rotor unmanned aerial vehicle, as figure 1 As shown: it includes a main rotor head 302 fixedly connected to the main shaft 1 of the drone, and the main rotor head is arranged perpendicular to the main shaft;

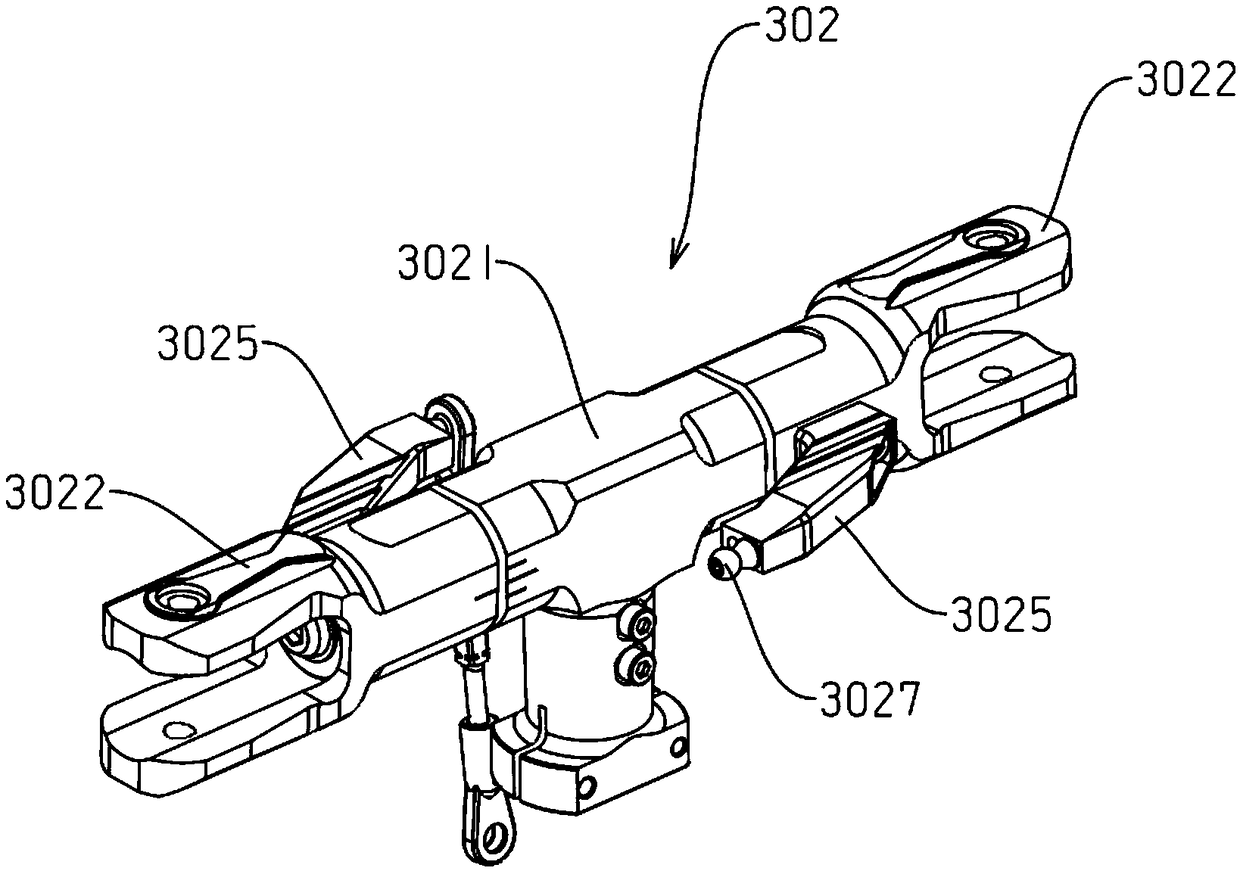

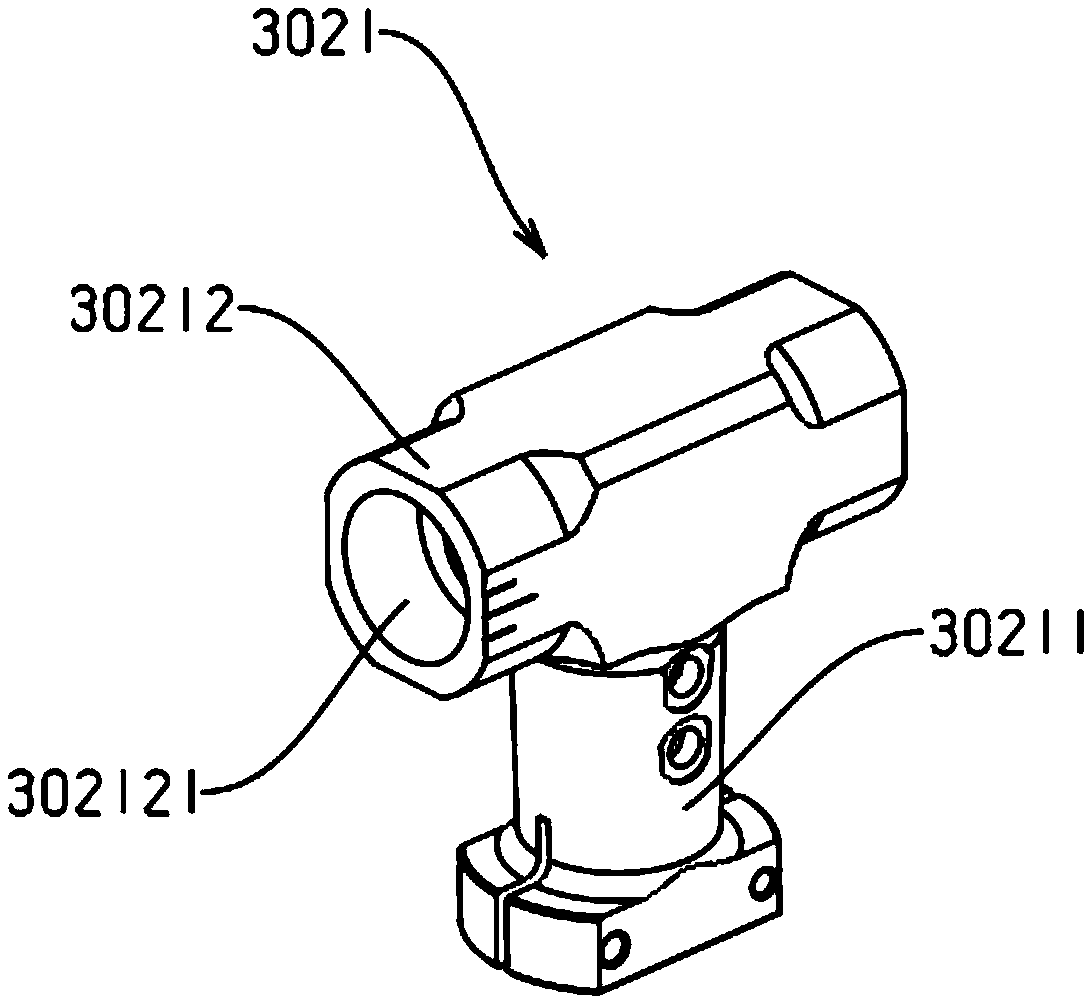

[0039] Such as Figure 2 to Figure 5 As shown: the main rotor head includes a central paddle seat 3021, the central paddle seat has a vertical arm 30211 and a cross arm 30212, and the central paddle seat is formed into a "T" shape by the cross arm and the vertical arm structure, the vertical arm is fixedly connected to the main shaft, and both ends of the cross arm are provided with a main blade clamp 3022 for clamping the main rotor, and one end of the main blade clamp is sleeved on the cross arm, and the Thrust bearing 3023 and at least one paddle angular contact bearing 3024 are provided at the part of the sleeve, and the two main paddle clips are rotatably connected to the cross arm through the thrust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com