Process for preparing connecting conductor material for power source system of new energy vehicle

A new energy vehicle, power supply technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of battery explosion, affecting battery life, strong corrosion, etc., to achieve the effect of convenient conductive connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description will be made with reference to preferred embodiments of the present invention. It should be understood, however, that the present invention may be embodied in various forms and should not be limited to the embodiments set forth herein.

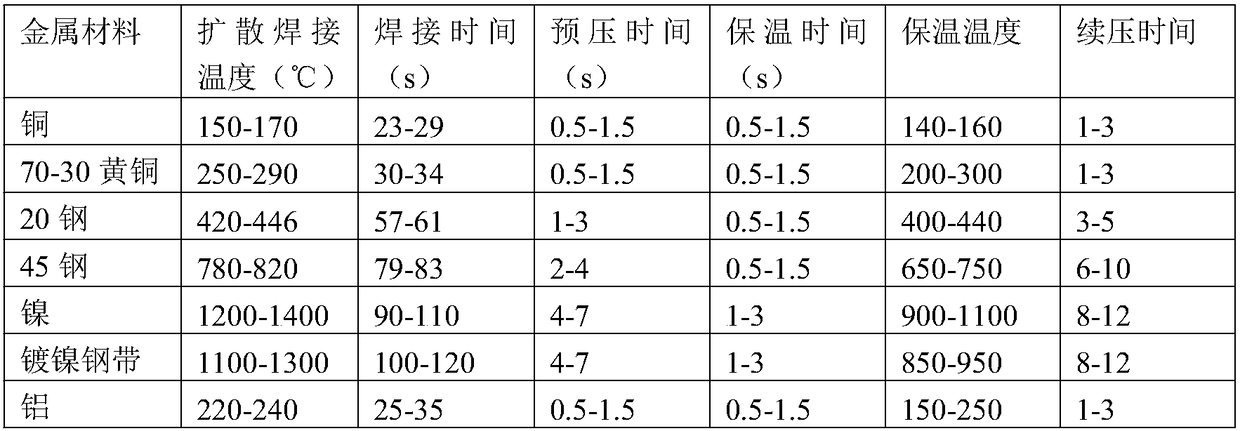

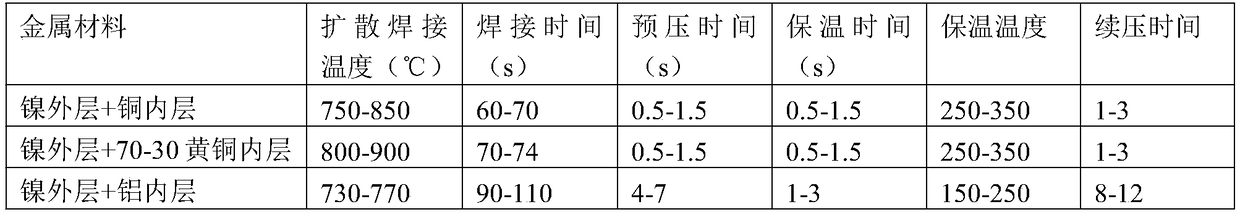

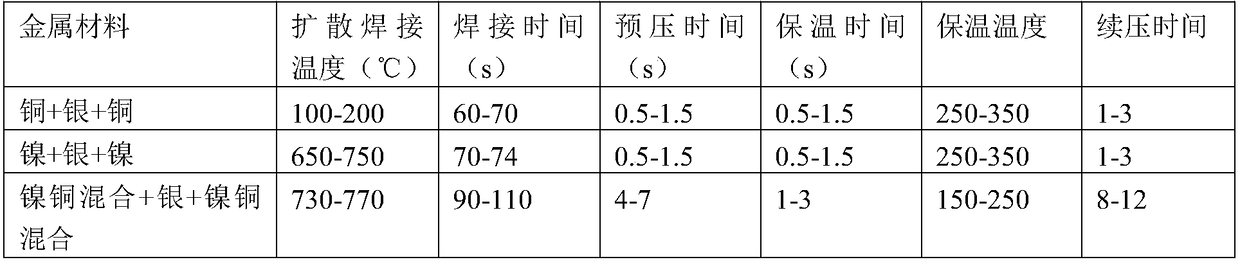

[0040] A preparation process for connecting conductor materials used in power supply systems of new energy vehicles, comprising the following steps: automatic feeding - automatic detection of material strips - automatic cutting - automatic loading - polymer diffusion welding - surface treatment - stamping Cutting—polishing—punching—polishing—electroplating—polishing—casing / dipping—automatic inspection—automatic packaging—finished products;

[0041] 1. Automatic feeding: first place the material with thickness: 0.1mm and width: 60mm on the automatic feeding machine, and use the automatic feeding machine for active feeding. The feeding speed is adjusted according to the cutting speed of the thick channel. Active ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com