Filter device comprising transmission cross-flow flat sheet membrane members and method

A filtration device and flat membrane technology, applied in the field of environmental engineering, can solve the problems of low wastewater treatment rate, clogging fouling and bacterial growth, etc., and achieve the effects of reducing membrane fouling, preventing bacterial growth, and stabilizing permeate flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

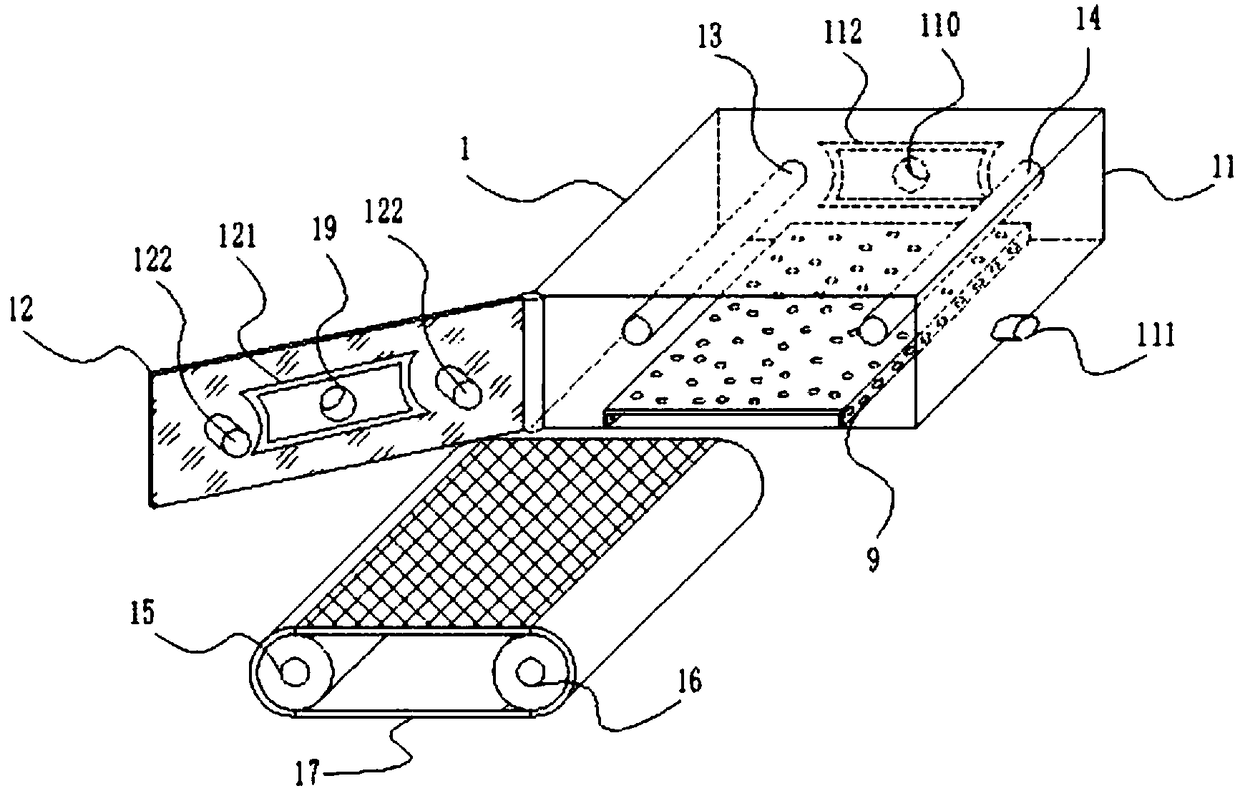

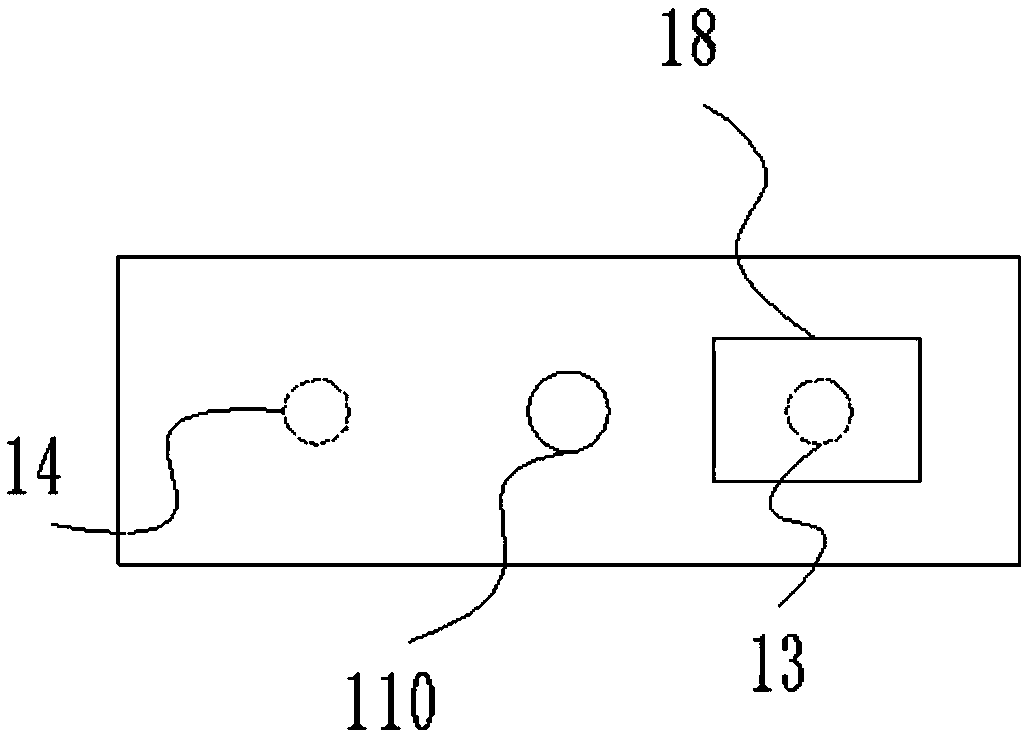

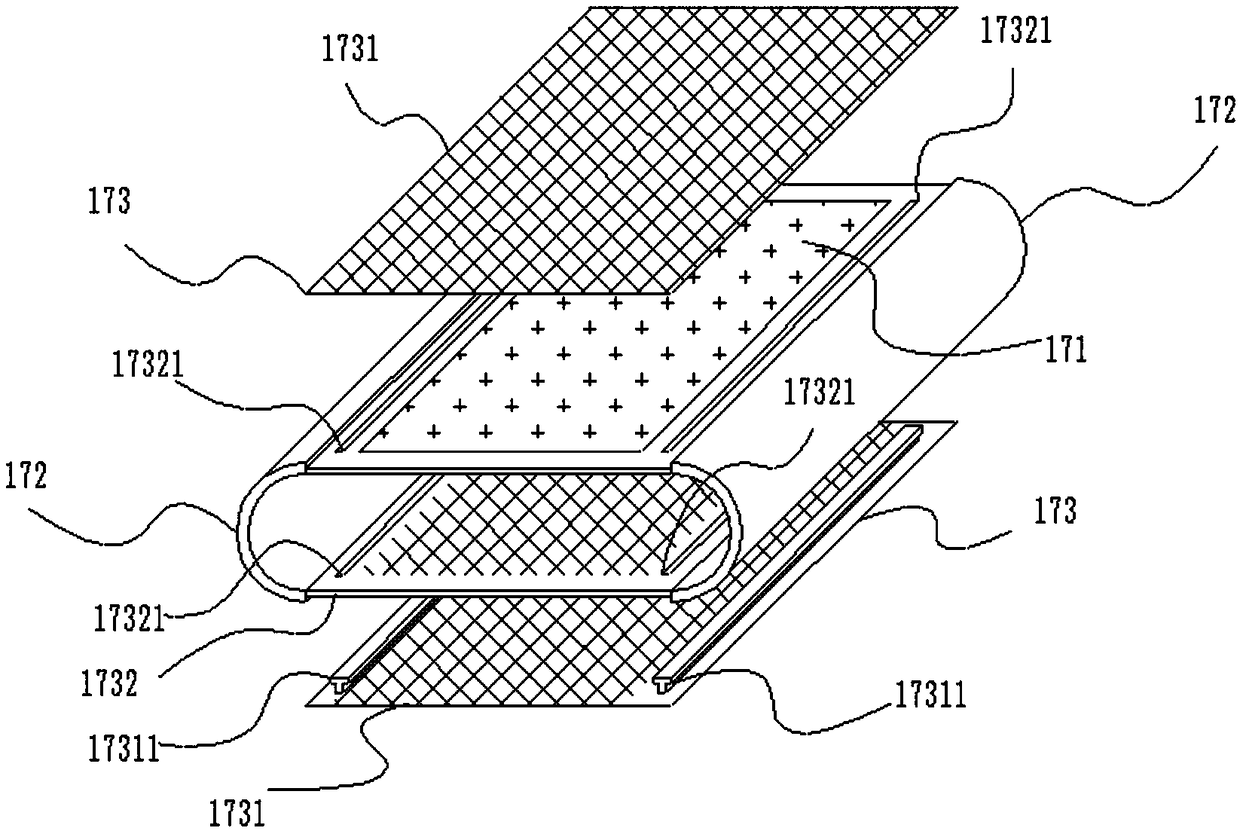

Embodiment 1

[0029] Such as Figure 4 As shown, a filter device composed of a transmission cross-flow flat membrane member, mainly includes a transmission cross-flow flat membrane member 1, an inlet tank 2, a collection tank 3, a pressure pump 41, a pressure meter 42, and an electronic flow meter 51 And water quality detector 71, such as Figure 4 As shown, the water inlet tank 2 is provided with a temperature controller 21 inside. The water inlet tank 2 is connected to the water inlets 19 of the three cross-flow flat membrane members 1 through the water inlet main pipe 4 and the three water inlet branch pipes 5 in turn. 4 is connected to the water inlet tank 2 through the original liquid return pipe 43, and the water inlet main pipe 4 is connected between the pressure pump 41 and the pressure meter 42 to increase the adjustability of the water pressure. The pressure pump 41 and the pressure meter 42 are arranged on the inlet main pipe 4 from left to right. There are three electronic flow me...

Embodiment 2

[0040] Such as Figure 4 As shown, a filter device composed of a transmission cross-flow flat membrane member, mainly includes a transmission cross-flow flat membrane member 1, an inlet tank 2, a collection tank 3, a pressure pump 41, a pressure meter 42, and an electronic flow meter 51 And water quality detector 71, such as Figure 4 As shown, the water inlet tank 2 is provided with a temperature controller 21 inside. The water inlet tank 2 is connected to the water inlets 19 of the three cross-flow flat membrane members 1 through the water inlet main pipe 4 and the three water inlet branch pipes 5 in turn. 4 is connected to the water inlet tank 2 through the original liquid return pipe 43, and the water inlet main pipe 4 is connected between the pressure pump 41 and the pressure meter 42 to increase the adjustability of the water pressure. The pressure pump 41 and the pressure meter 42 are arranged on the inlet main pipe 4 from left to right. There are three electronic flow me...

Embodiment 3

[0051] Such as Figure 4 As shown, a filter device composed of a transmission cross-flow flat membrane member, mainly includes a transmission cross-flow flat membrane member 1, an inlet tank 2, a collection tank 3, a pressure pump 41, a pressure meter 42, and an electronic flow meter 51 And water quality detector 71, such as Figure 4 As shown, the water inlet tank 2 is provided with a temperature controller 21 inside. The water inlet tank 2 is connected to the water inlets 19 of the three cross-flow flat membrane members 1 through the water inlet main pipe 4 and the three water inlet branch pipes 5 in sequence. 4 is connected to the water inlet tank 2 through the original liquid return pipe 43, and the water inlet main pipe 4 is connected between the pressure pump 41 and the pressure meter 42 to increase the adjustability of the water pressure. The pressure pump 41 and the pressure meter 42 are arranged on the inlet main pipe 4 from left to right. There are three electronic flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com