Method for treating tail gas produced by thermal desorption of contaminated soil through pulse heating

A technology of pulse heating and soil heating, applied in the field of contaminated soil remediation, can solve the problems of not fundamentally decomposing pollutants, the need for activated carbon to be reprocessed, and increasing the processing cost, to achieve the effect of reducing energy consumption, saving costs and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar modules or modules having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

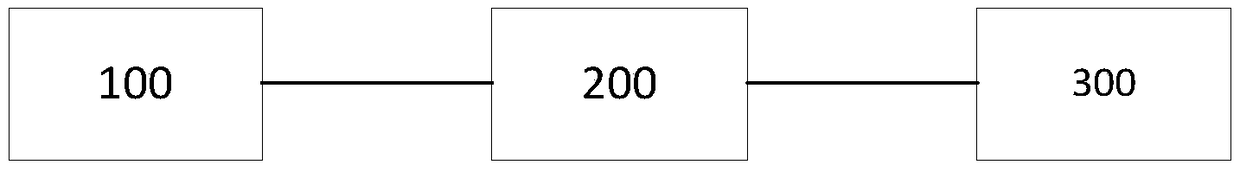

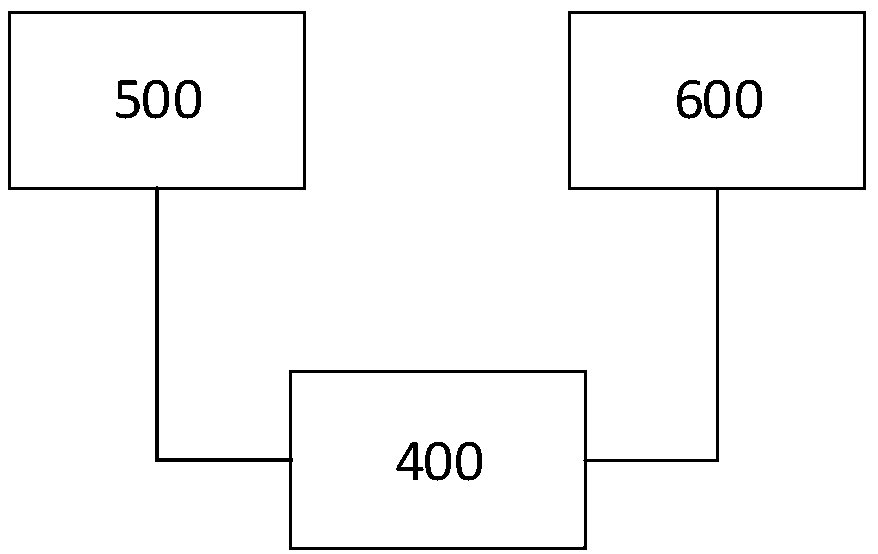

[0029] refer to figure 1 , according to an embodiment of the present invention, the method includes a dedusting treatment reactor 100 , a pulse heating catalytic degradation reactor 200 and an absorption treatment reactor 300 . According to an embodiment of the present invention, the dust removal treatment reactor 100 is used to remove particulate matter in the tail gas, the pulse heating type catalytic degradation reactor 200 is connected with the dust removal treatment reactor 100, and is used to purify the tail gas, and the absorption trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com