Manufacturing method for air purification and filtering skeleton supporting material

An air filter material and support material technology, applied in the field of indoor air purification material preparation, can solve the problems of insufficient environmental protection of plant fibers, lack of strength of base paper, large quantitative fluctuation of paper evenness difference, etc. The effect of overall air resistance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

[0022] A method for manufacturing an air purification filter skeleton support material, comprising the following steps:

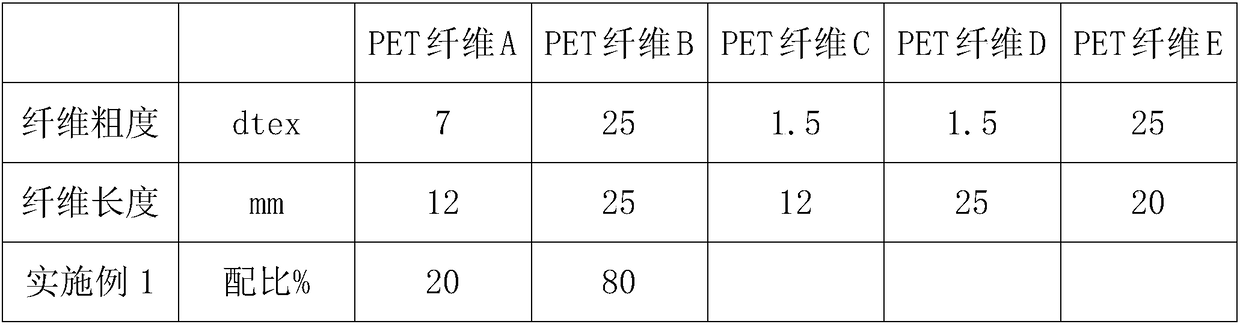

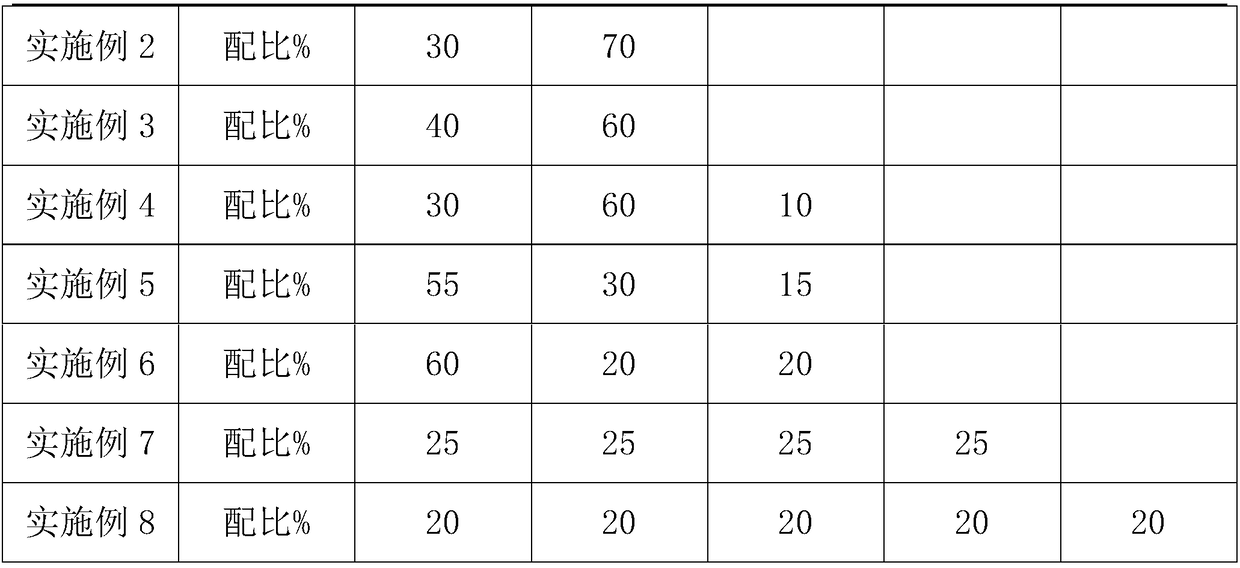

[0023] (1) Add PET fibers of at least two specifications in proportion to the pulp tank of the beater for disentanglement and beating treatment to obtain mixed fibers, the concentration of the mixed fiber slurry is controlled between 3-5%, and the pH value is adjusted to 9 , and heated to 120°C and stirred for 5 minutes, then diluted with cold water to a concentration of 0.5-0.7%, lowered to room temperature and adjusted to PH to 6, and added dispersant and wet strength agent to continue stirring for 10 minutes, PET fiber specification requirements The thickness is between 1.5-25dtex and the length is between 12-25mm;

[0024] (2), the mixed fiber is copied into base paper through an inclined wire paper machine;

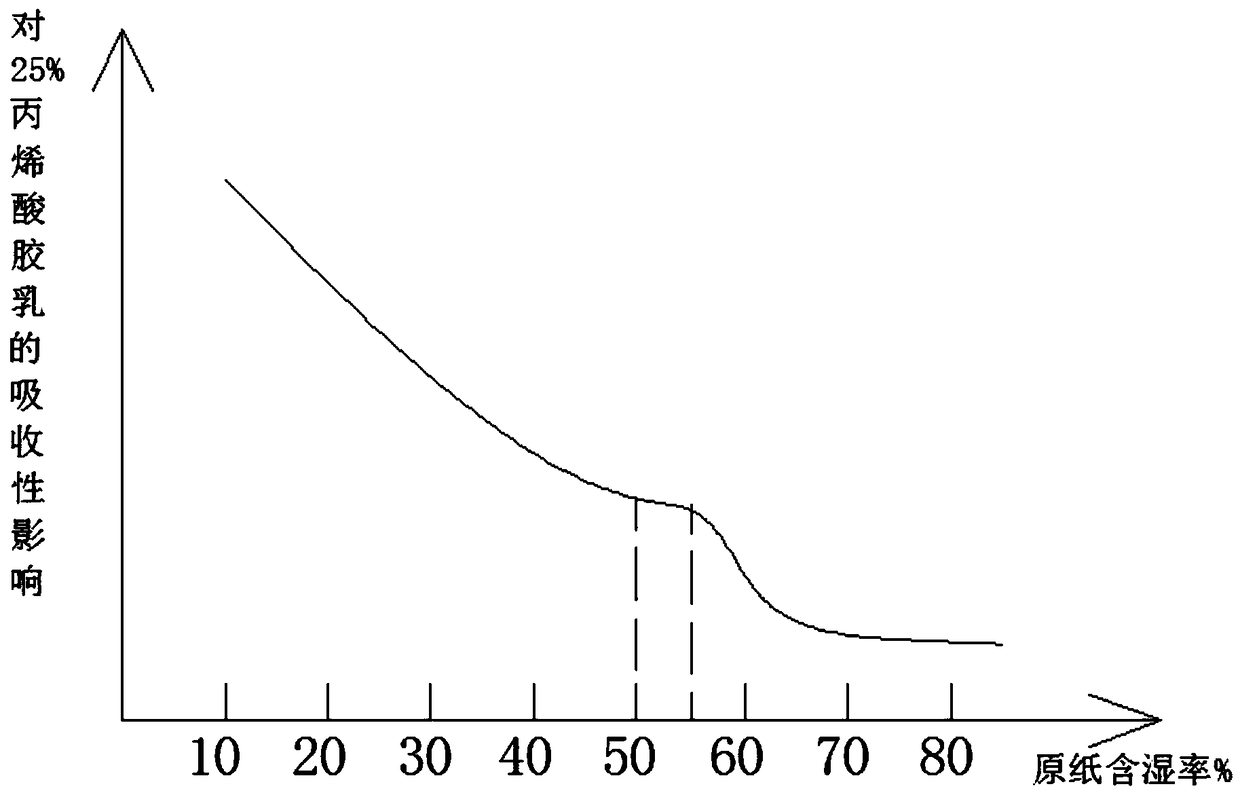

[0025] (3), d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com