Shelling equipment for removing chestnut outer shells based on rotating centrifugal force

A technology of rotating centrifugal force and chestnut, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of easy cutting of chestnuts, cumbersome operation, etc., and achieve the effect of good cutting effect and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

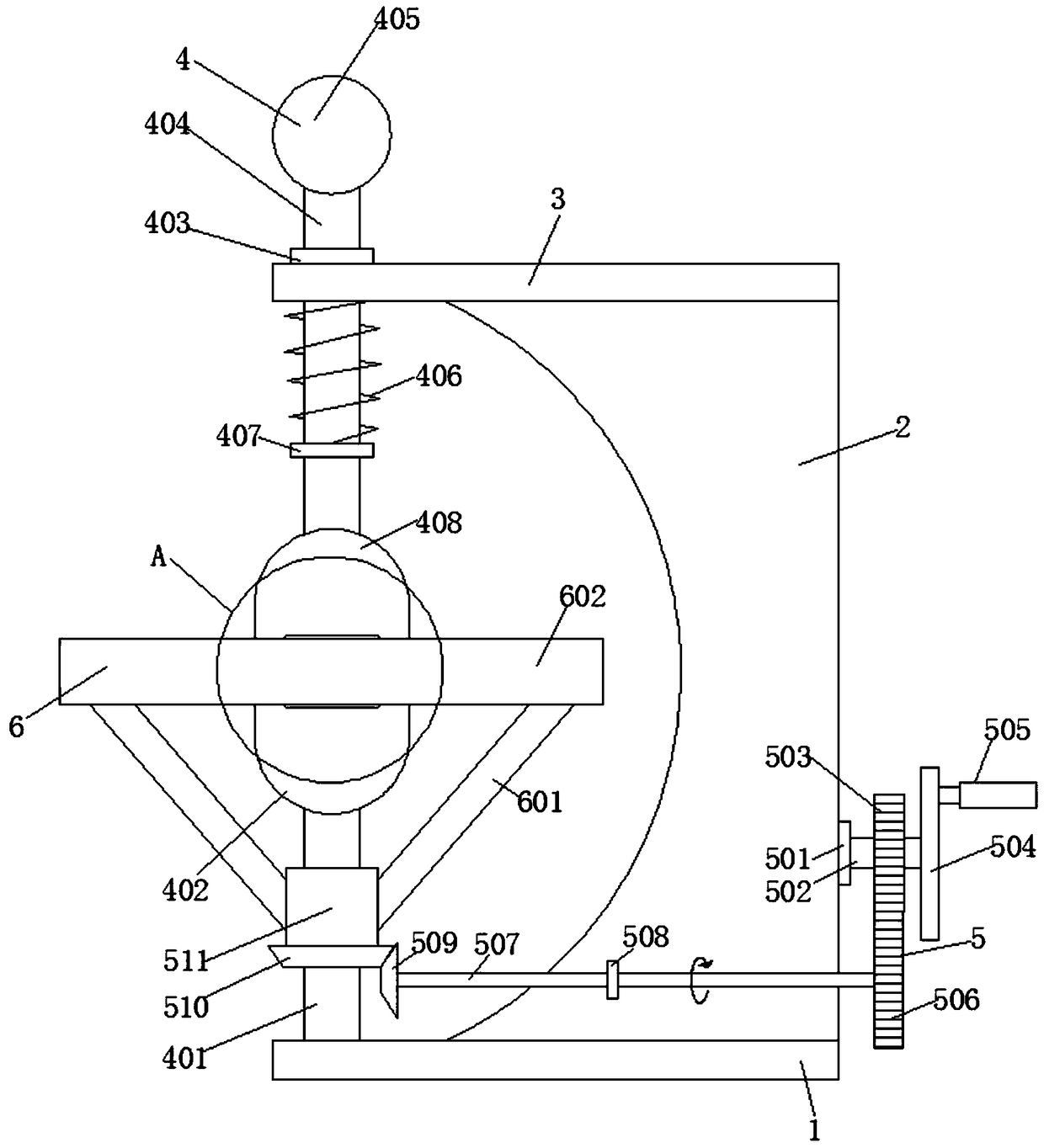

[0035] Embodiments of the present invention provide a shelling device for removing chestnut shells based on rotating centrifugal force, such as Figure 1-7As shown, it includes a lower base 1, the top of the lower base 1 is fixedly connected with a support block 2, the top of the support block 2 is fixedly connected with an upper base 3, and the upper base 3 and the lower base 1 are arranged on the left side of the support block 2 There is a clamping device 4, a transmission device 5 is arranged on the clamping device 4, and a rotary ring cutting device 6 is arranged on the transmission device 5.

[0036] The clamping device 4 comprises a support rod 401, a first clamping block 402, a limit ring 403, a movable rod 404, a pull handle 405, a supporting spring 406, a fixed ring 407 and a second clamping block 408, and the top of the lower base 1 is The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com