Syntactic rigid PUR/PIR foam boardstock

A technology of rigid polyurethane and polyisocyanate, which is applied in the field of rigid polyurethane/polyisocyanate foam products and can solve the problems of undisclosed double-mesh foam and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

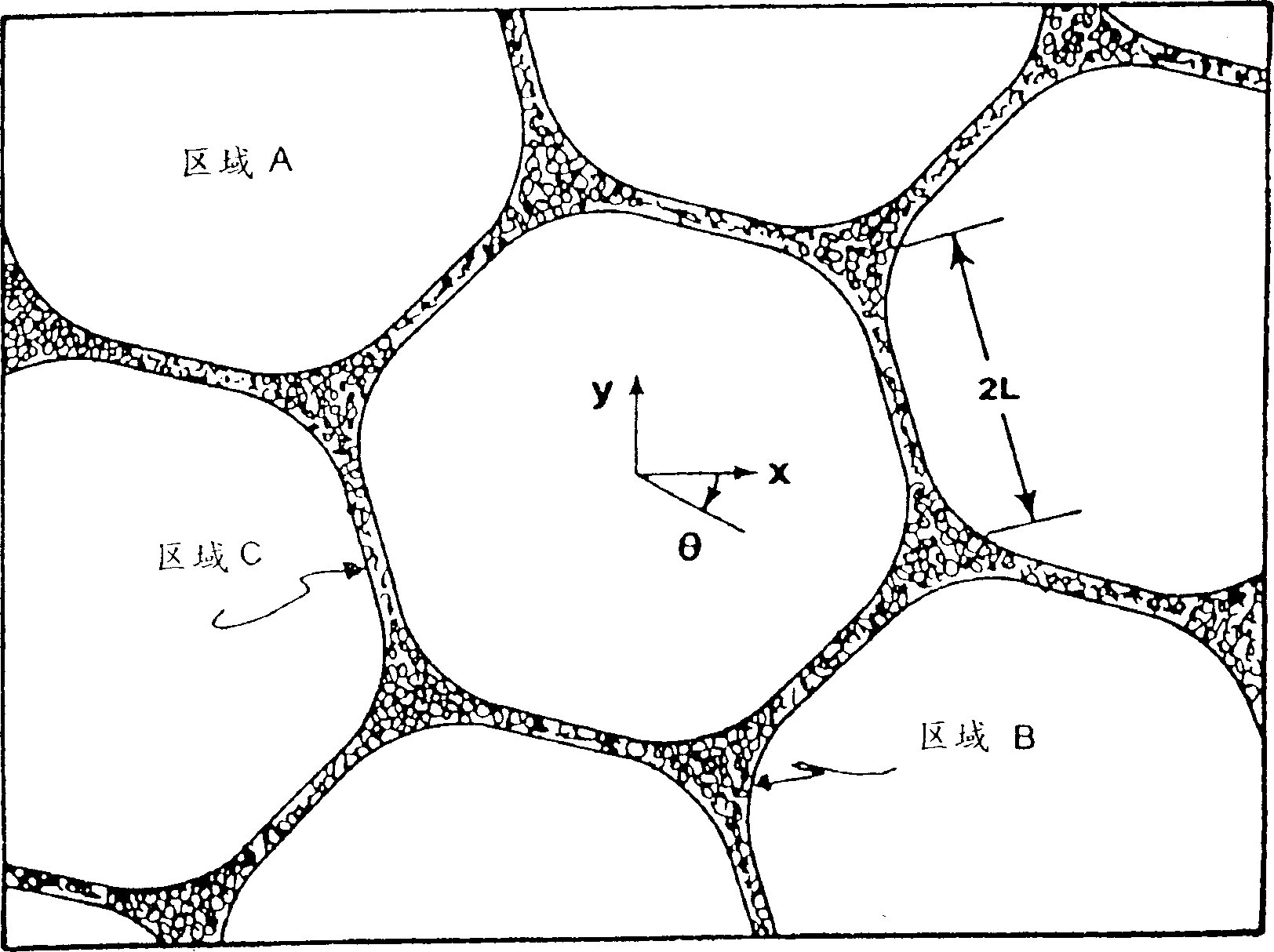

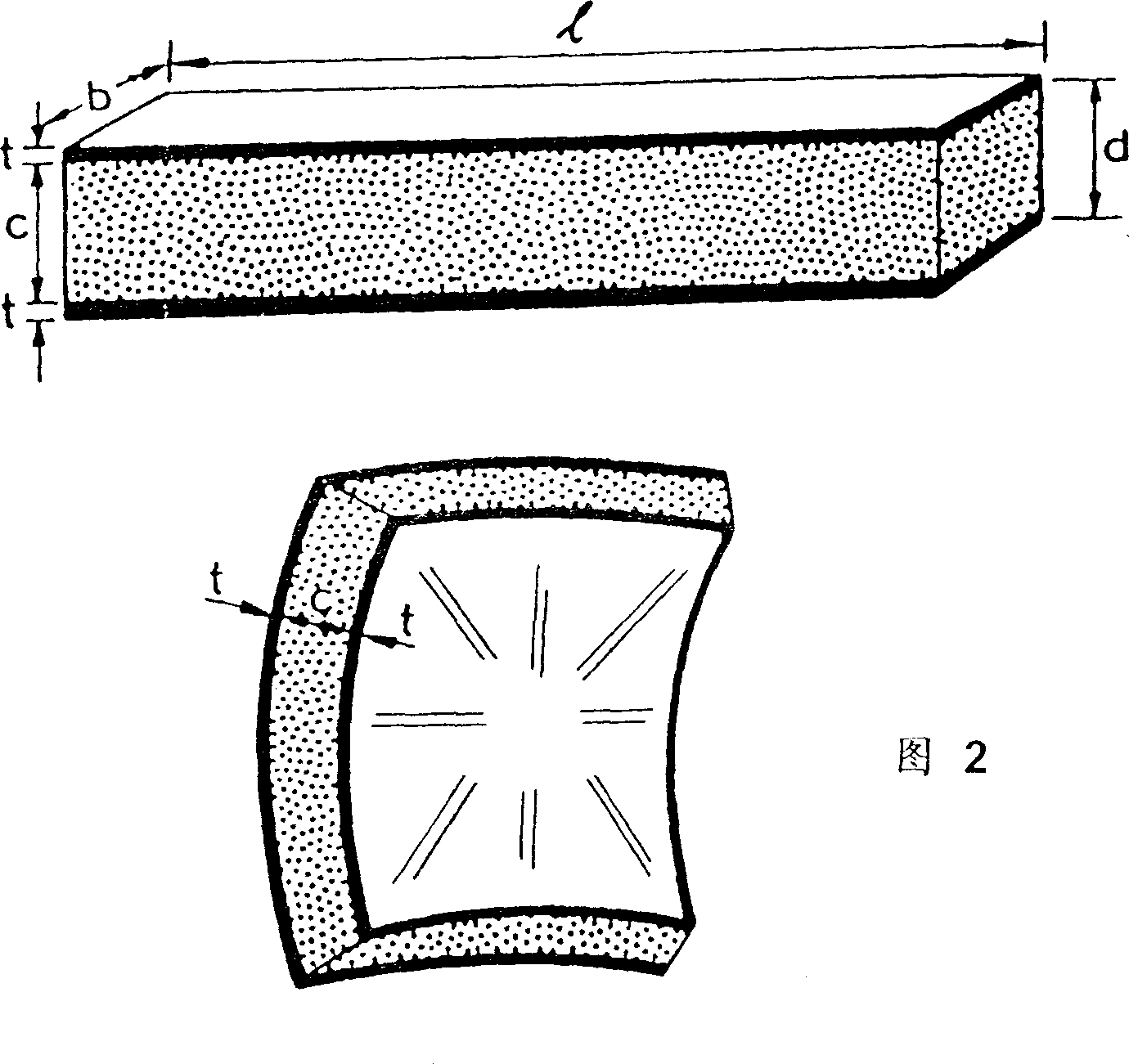

[0027] The present invention is directed to an improved rigid foam product comprising microspheres.

[0028] The hollow microspheres used here are known. Commercially available microspheres include Expancel 551 DE from Expancel Inc. Z-Light W-1000, provided by Zeelan Industries; Dualite M6032AE, provided by Pierce & Stevens Corporation; Scotchlite S-Series, provided by 3M Company; and QCEL300 and QCEL 650, provided by PQ Corporaion. Expancel and Dualite type microspheres, both are expandable and hollow microspheres, composed of a thin shell of 1,1-dichloroethylene and acrylonitrile copolymer, Z-Light W-1000 microspheres The shells of Scotchlite and QCEL are ceramic, while the microspheres of Scotchlite and QCEL are composed of glass shells. The microspheres of Expancel and Pierce & Stevens generally contain a volatile hydrocarbon inside. These microspheres can not only contain isobutane, isopentane or cyclohexane, but also can be made with conventional low boiling point solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com