A lamp assembly for use in a headlamp

A lamp assembly and headlamp technology, which can be applied to parts of lighting devices, semiconductor devices of light-emitting elements, headlights, etc., and can solve problems such as misalignment and poor registration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

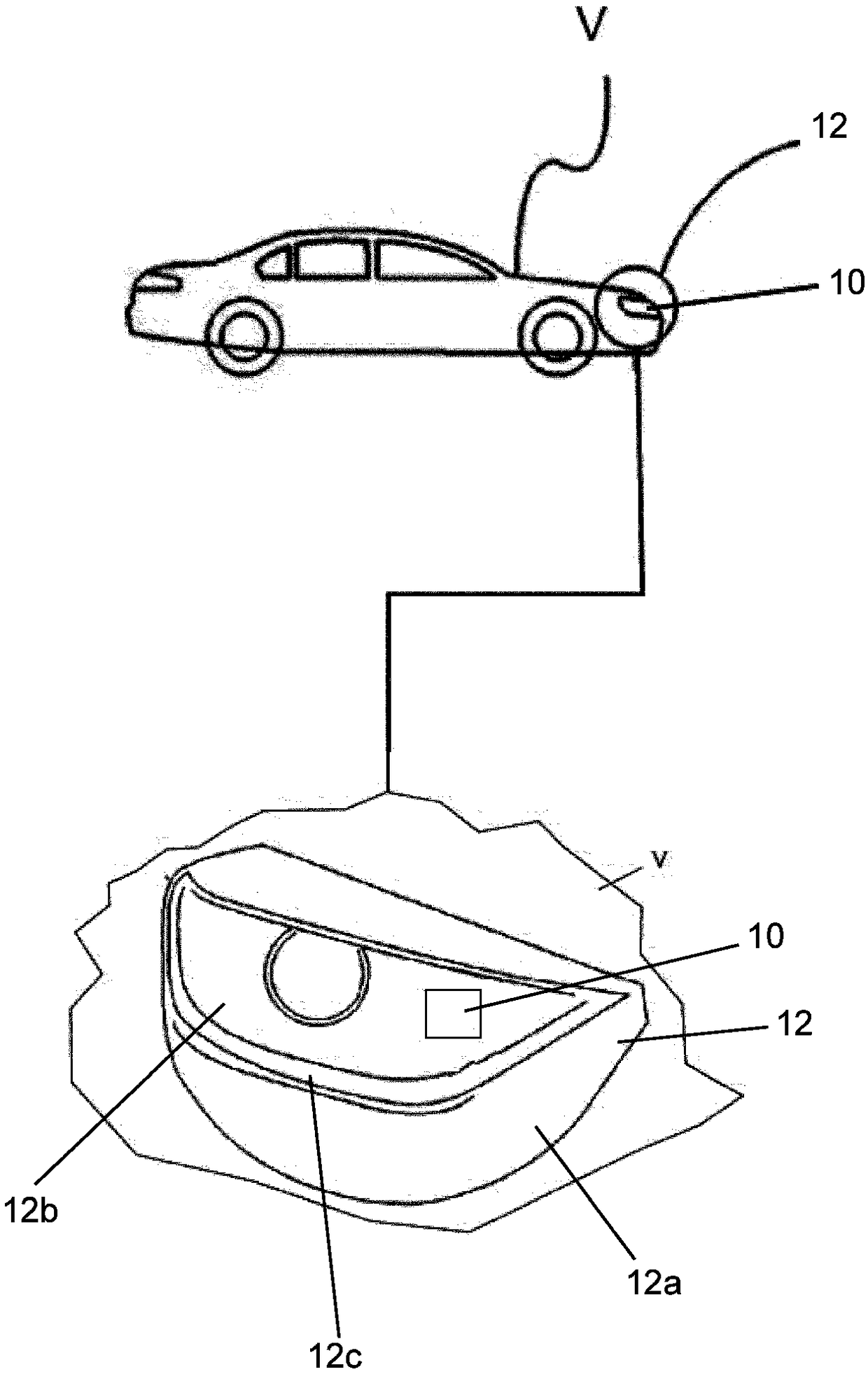

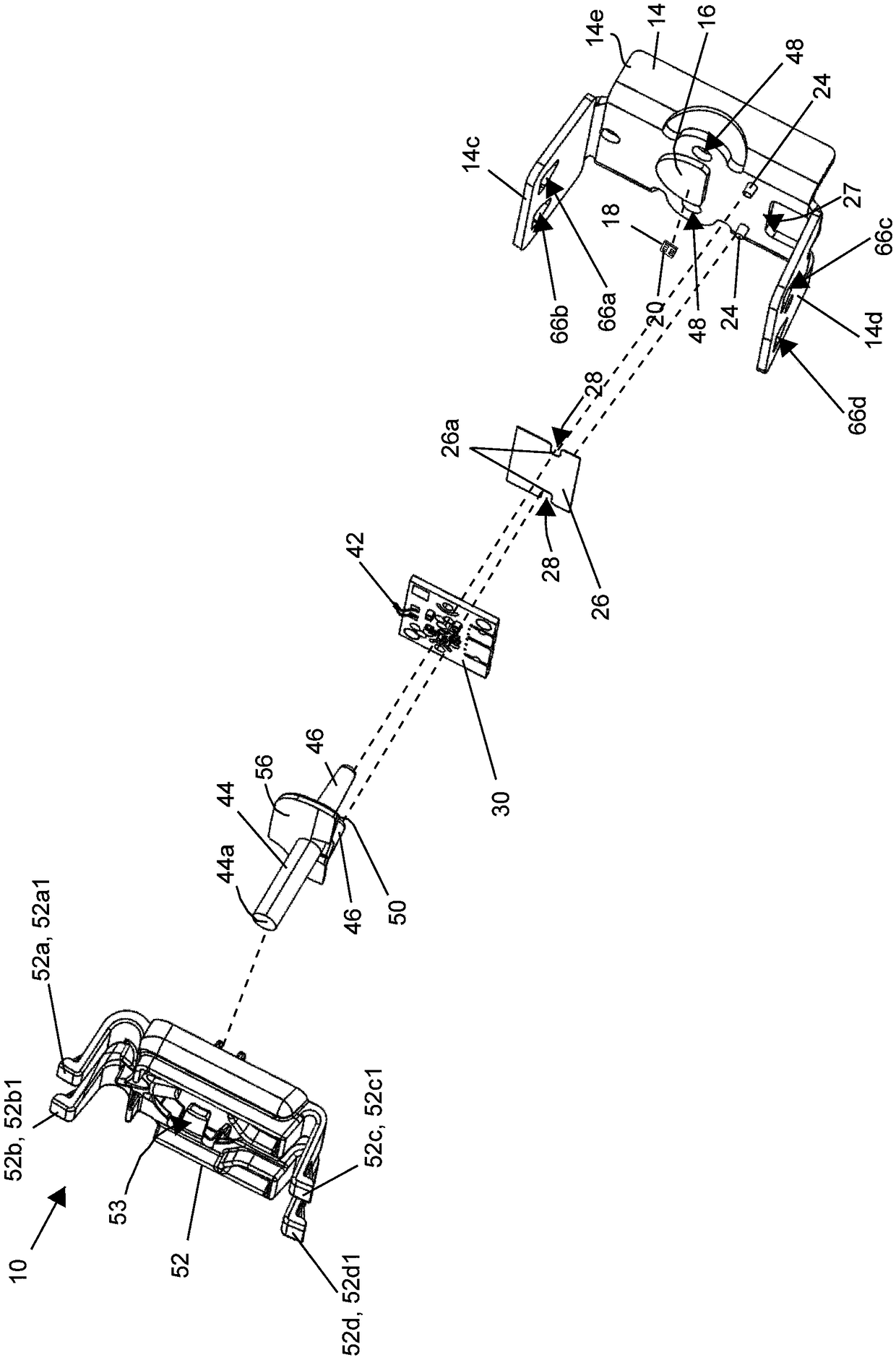

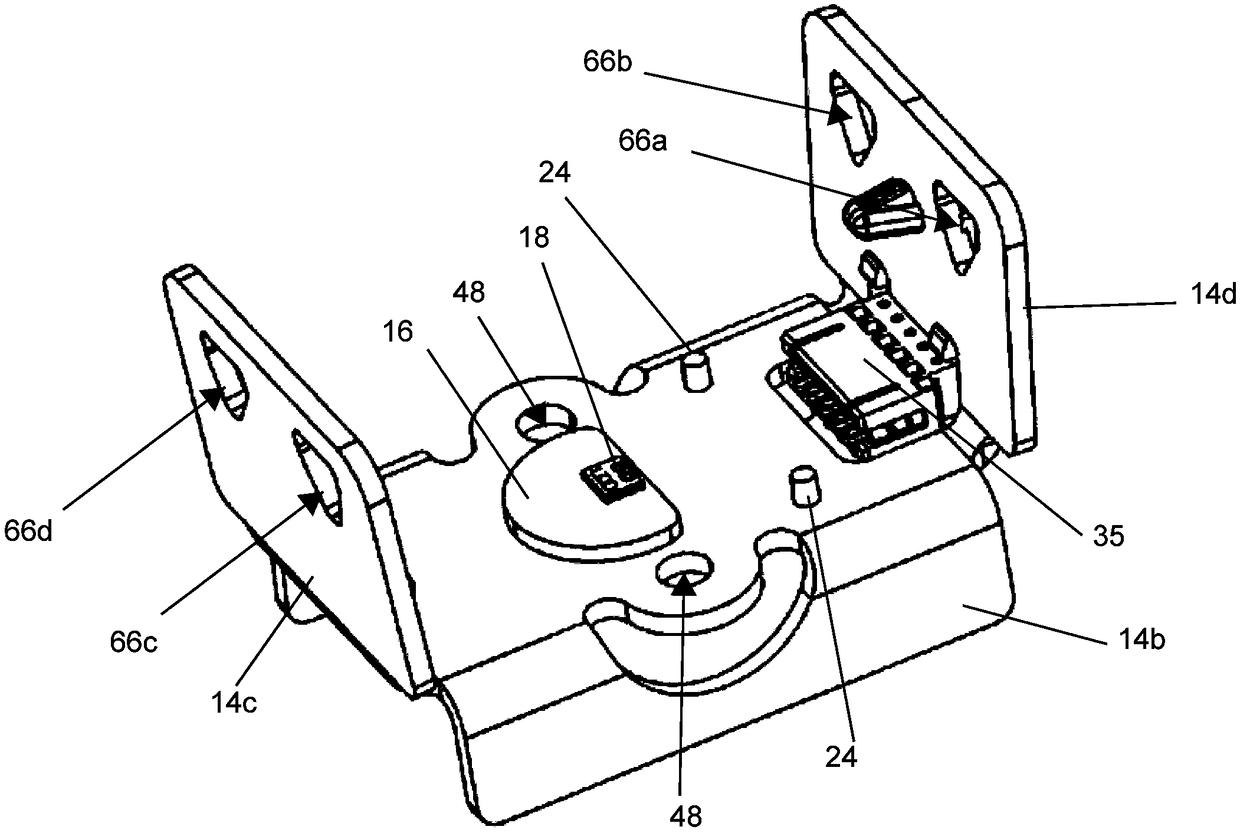

[0048] now refer to figure 1 , the lamp assembly 10 is shown installed in a headlamp assembly 12 of a vehicle V. As shown in FIG. The headlamp assembly 12 includes a frame or housing 12a , a lens 12b and a seal 12c that generally seals the lamp assembly 10 in the headlamp assembly 12 . Lamp assembly 10 includes a heat sink 14 stamped from a single sheet of material (not shown) and configured as figure 2 shown in the exploded diagram. The heat sink 14 is an integral unitary or monolithic structure, and is machined or folded to include a first wall 14a, a second wall 14b generally opposite the first wall 14a ( image 3 ), a first end wall 14c and a second end wall 14d generally opposite to the first end wall 14c, such as figure 2shown. Note that the heat sink 14 includes a crescent or half-moon shaped landing pad or area 16 adapted to receive a light source 18 which may include at least one or more light emitting diodes (LEDs) 20 . In the figure, at least one LED 20 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com