Thermal ball valve resistant to leakage

A leak-proof and thermal technology, applied to the valve details, valve device, valve housing structure, etc., to achieve the effect of simple and practical structure, convenient operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

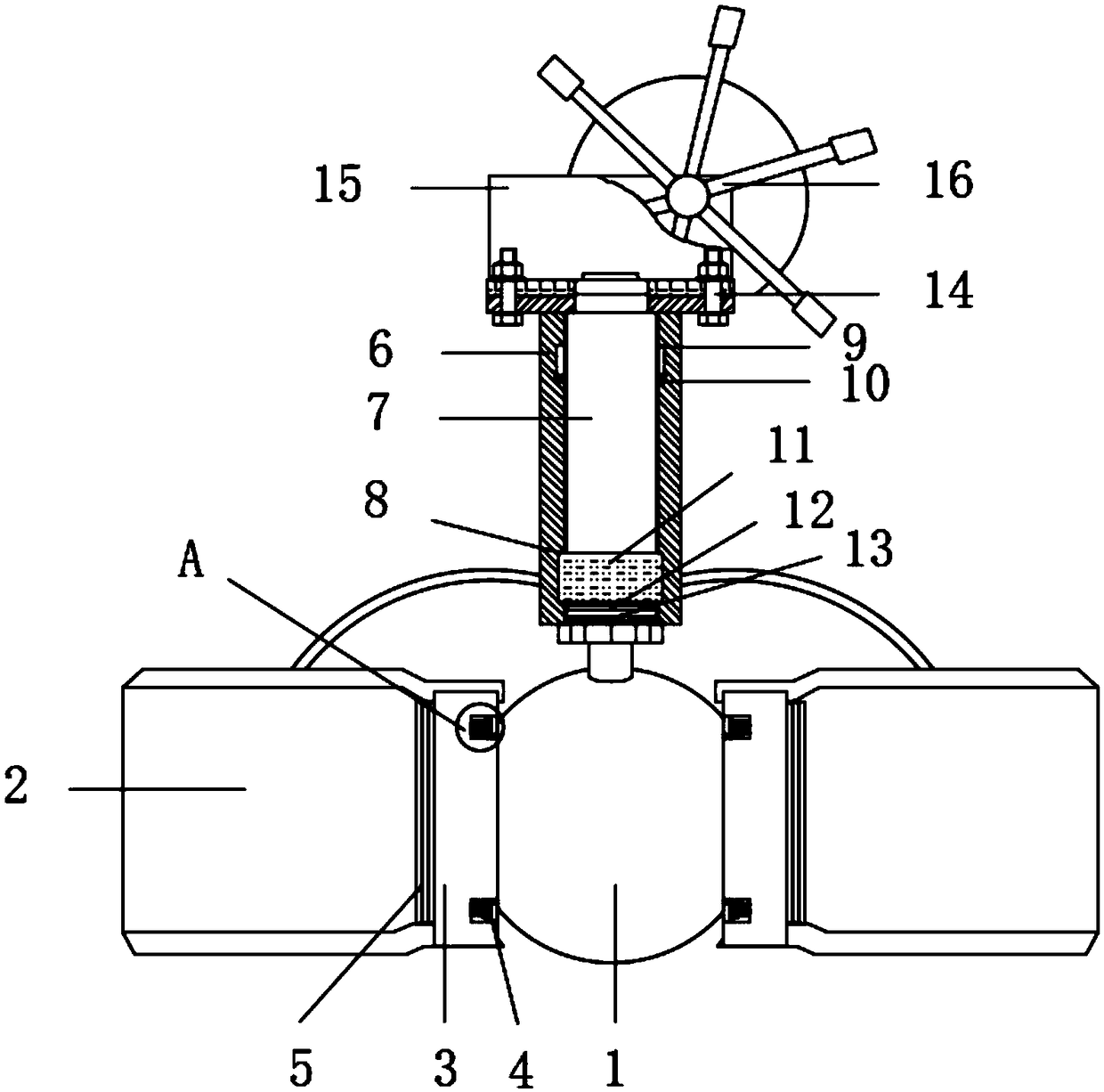

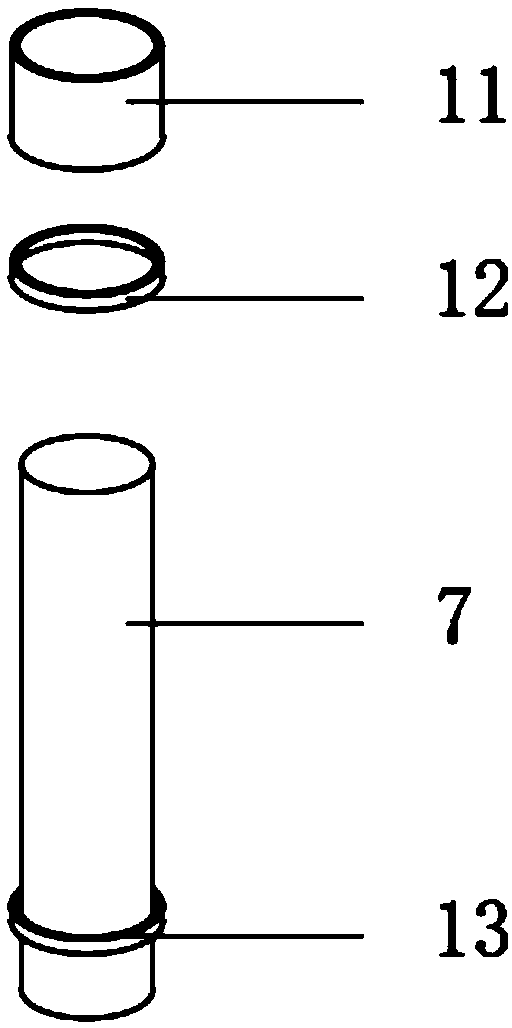

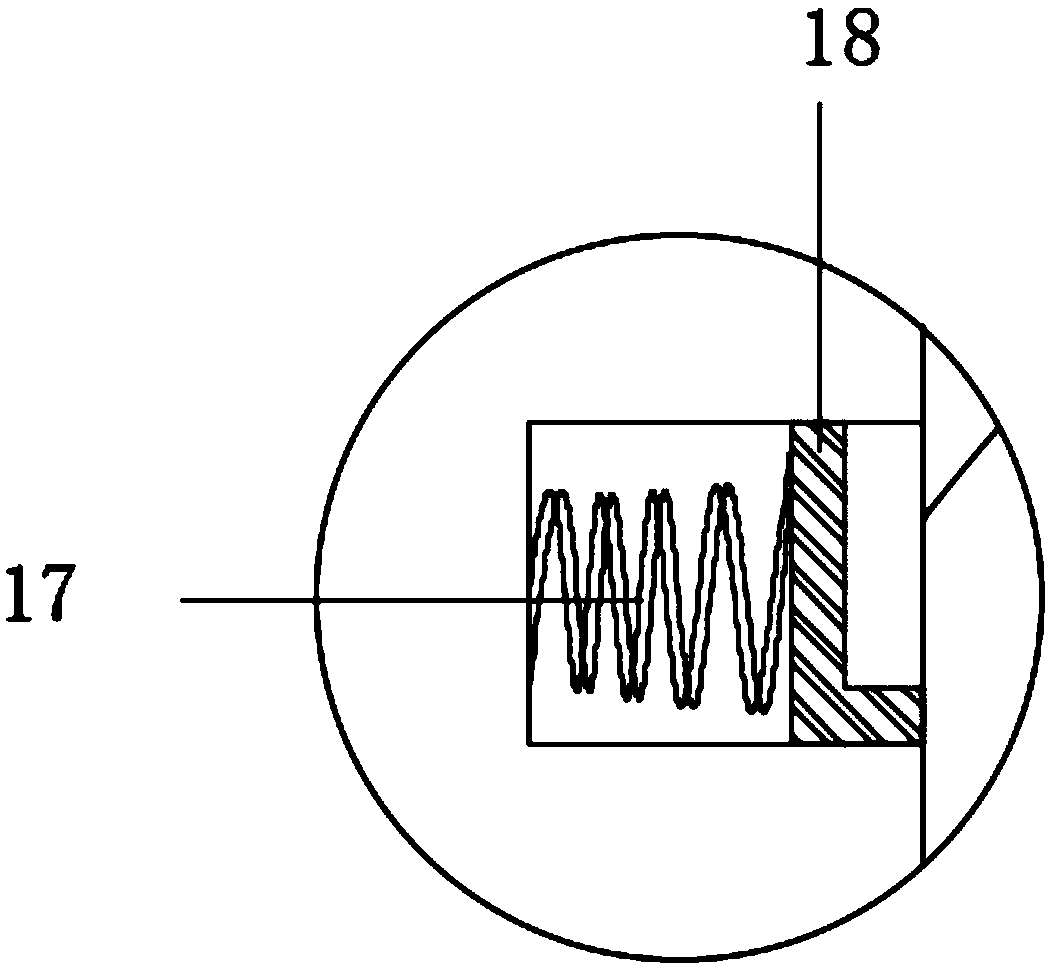

[0019] like Figure 1-3 As shown in the figure, this specific embodiment adopts the following technical solutions: an anti-leakage thermal ball valve, comprising a ball body 1, a floating valve seat 3 is connected on both sides of the ball body 1, and the floating valve seat 3 is close to one side of the ball body 1. Both ends are connected with a buffer limit mechanism 4, the buffer limit mechanism 4 is provided with a spring 17, the spring 17 is connected with the floating valve seat 3, and the other end of the spring 17 is connected with a contact block 18, the contact The side of the block 18 away from the spring 17 is connected with the ball 1, the spring 17 is connected with the ball 1 through the contact block 18, the side of the floating valve seat 3 away from the ball 1 is connected with the connecting pipe 2, the The connection between the floating valve seat 3 and the connecting pipe 2 is provided with a No. 1 sealing ring 5, the upper end of the ball 1 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com