Cone frustum tooth clutch

A truncated cone and clutch technology, applied in the field of clutches, can solve the problems of high processing cost, high cost, and low cost of jaw clutches, and achieve the effects of simple and reliable separation and docking, low cost, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

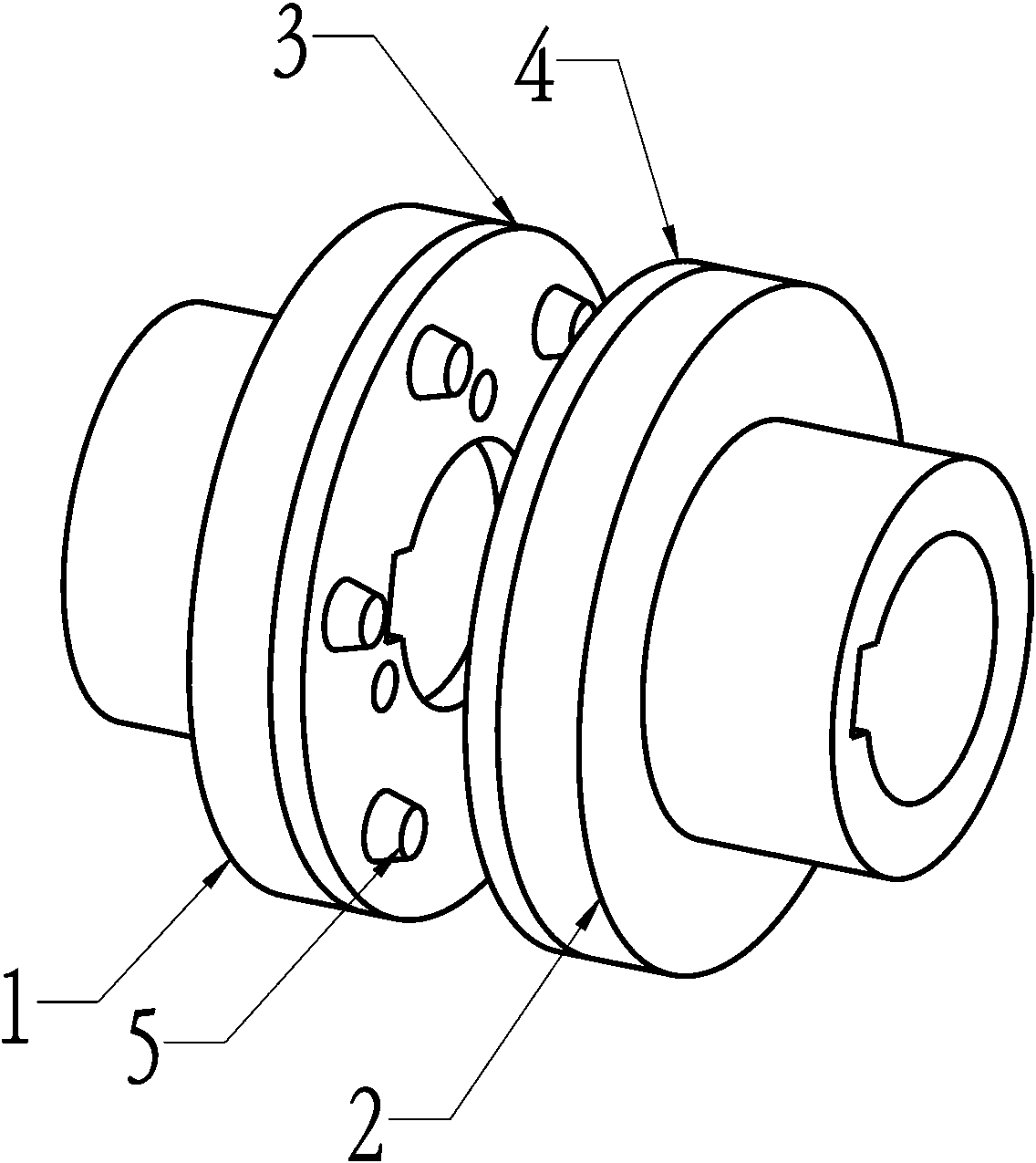

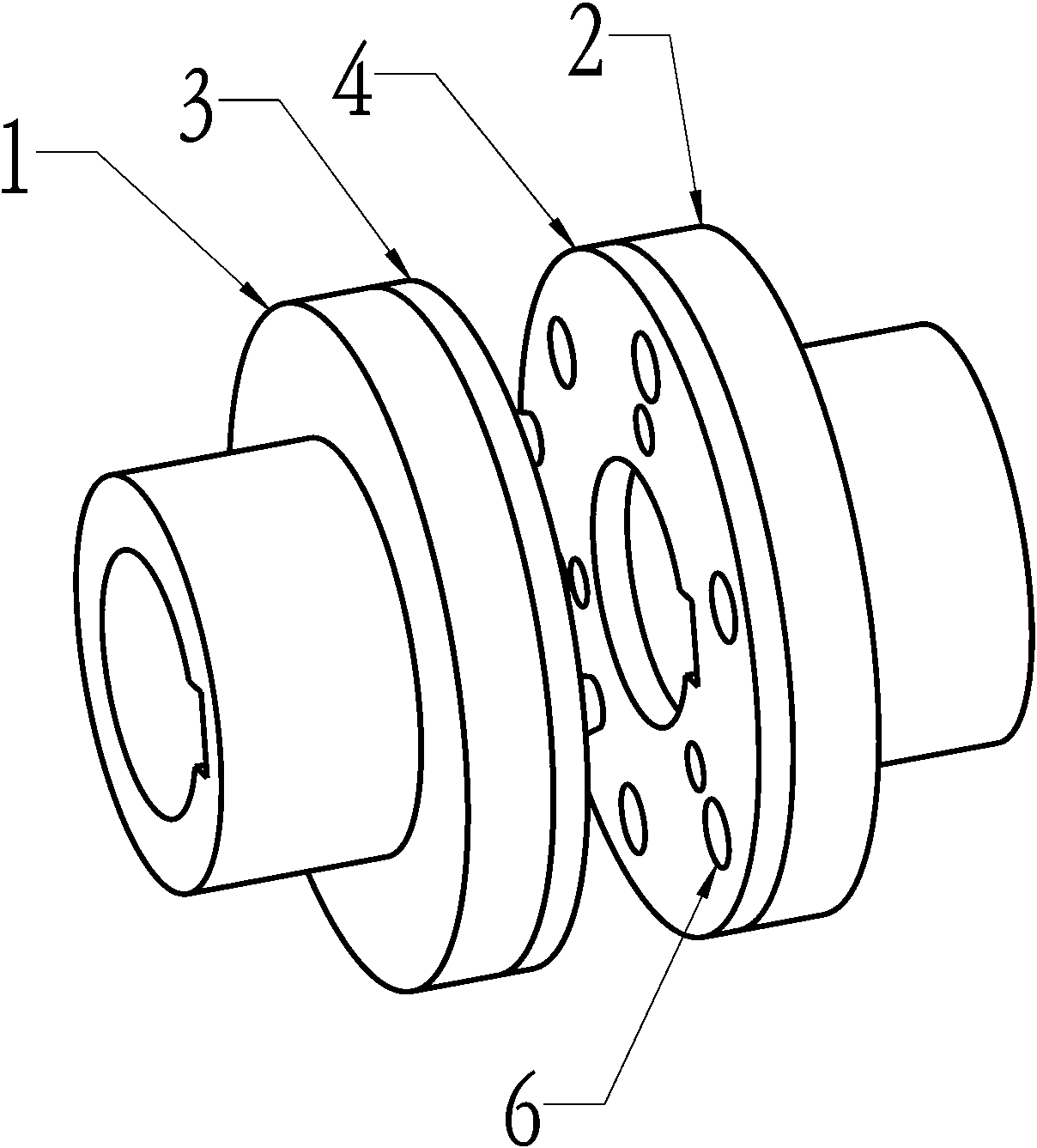

[0010] In the figure, the conical table tooth clutch is composed of a left clutch disc 1 and a right clutch disc 2. The tooth shape of the clutch is a conical table tooth. Hole 6; frustoconical tooth 5 and truncated conical hole 6 are corresponding in quantity and size. relationship; the front end of the left clutch disc 1 is fixed with a tooth plate 3, and the right clutch disc 2 is fixed with an orifice plate 4; the conical table teeth 5 are evenly distributed around the axis of the clutch disc and fixed on the end face of the tooth plate 3; The axes of the discs are evenly distributed and fixed on the end face of the orifice plate 4 . The number of truncated conical teeth 5 is greater than 2, and the number of truncated conical holes 6 is greater than 2. The tooth plate 3, the orifice plate 4 and the conical table tooth 5 are vulnerable independent parts, which are processed separately for easy replacement.

[0011] The working method of the conical truncated tooth clutch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com