Drill bit for breaking waste pipe pile, and method for breaking waste pipe pile and pouring new pile

A waste and pipe pile technology, applied in the direction of drill bits, sheet pile walls, drilling equipment, etc., can solve the problems of delay in construction period, high rent, limited length of pile pulling casing, etc., to increase the depth and diameter of piles, and reduce the holding capacity The effect of reducing cost and speeding up construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

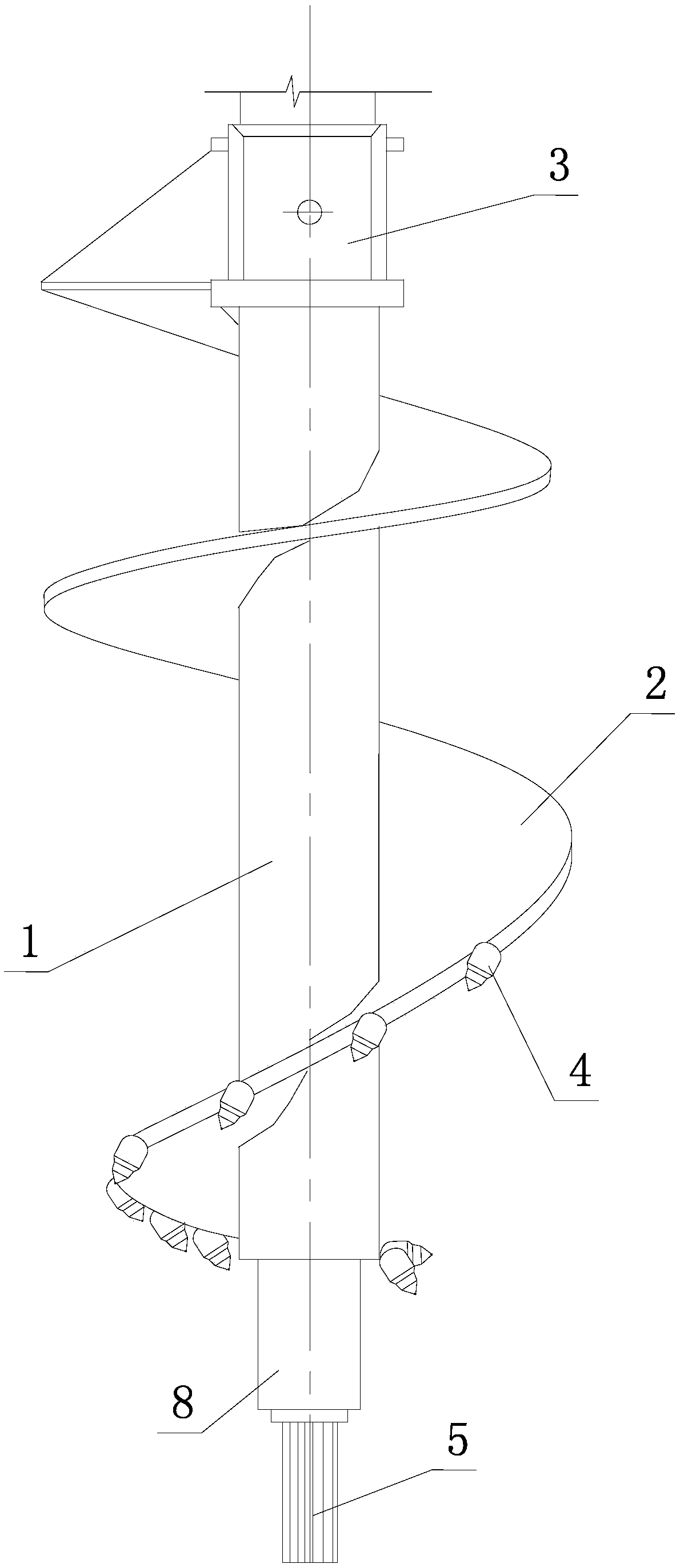

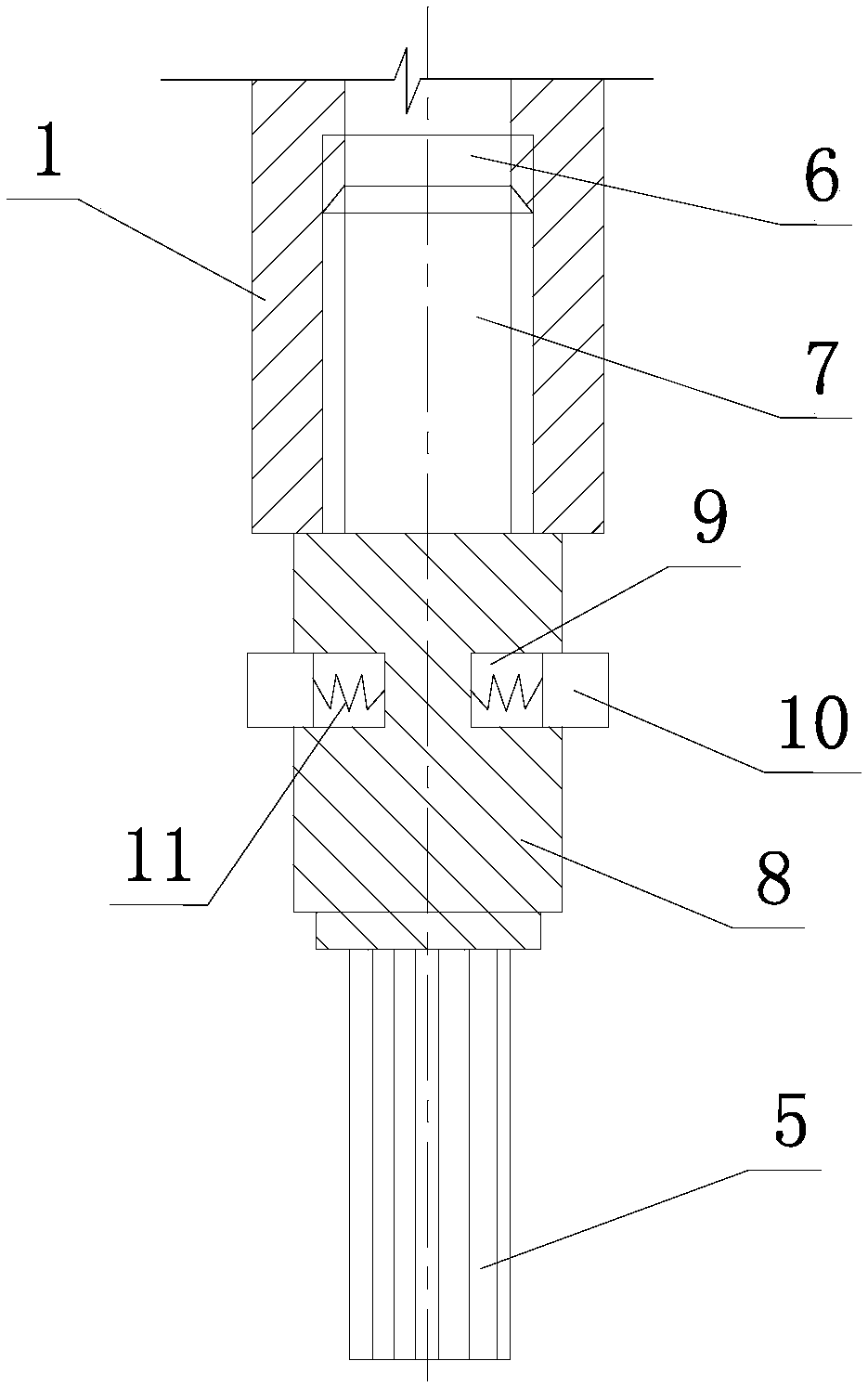

[0021] As shown in the figure, the drill bit for removing waste pipe piles of the present invention includes a mandrel 1 with a helical blade 2 on the outer circumference of the mandrel 1 and a connecting part 3 for docking with the drill pipe of the drilling rig at the top of the mandrel 1 . The helical blade 2 is provided with a plurality of picks 4 at least below the middle, and of course, the helical blade 2 may also be provided with picks 4 from top to bottom. And, even, can replace pick 4 with gear teeth, to obtain better rock-breaking effect.

[0022] The bottom of the mandrel 1 is provided with a vertical tendon 5 welded by a plurality of short steel bars, the tendon 5 is coaxial with the mandrel 1 and the outer diameter of the tendon 5 is less than or equal to the inner diameter of the waste pipe pile to be broken. All the above-mentioned short steel bars are welded together against each other to enhance their strength and supporting performance.

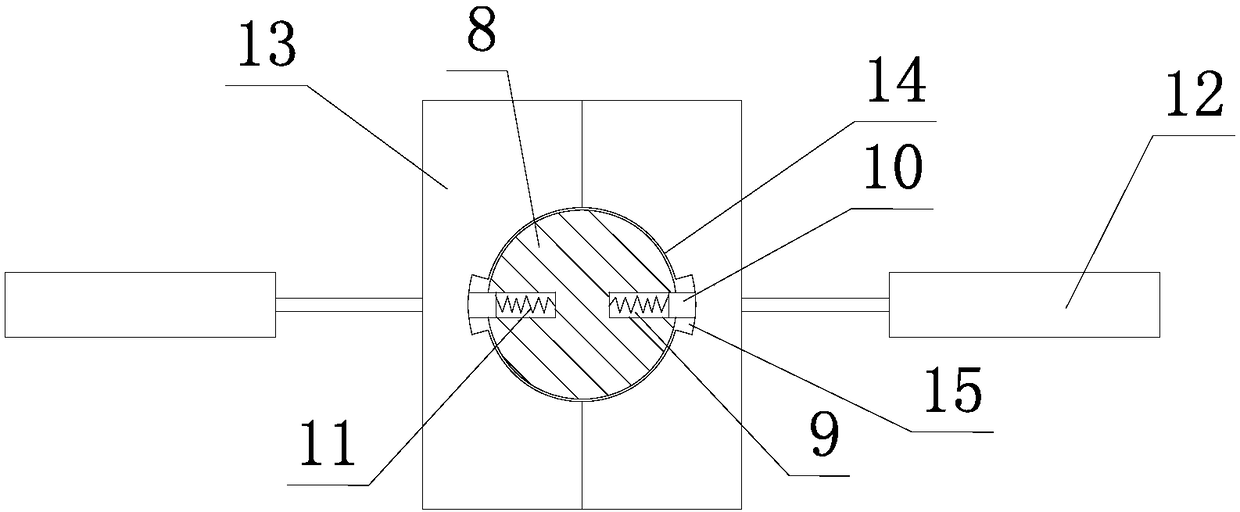

[0023] Specificall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com