A shimmy drilling tool for downhole friction and torsion reduction

A drilling tool and resonant cavity technology, which is applied in vibration drilling and other directions, can solve the problems of unfavorable drilling fluid overall circulation, inability to be widely used, and large size, and achieve the effects of improving drilling efficiency, simple structure, and short overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

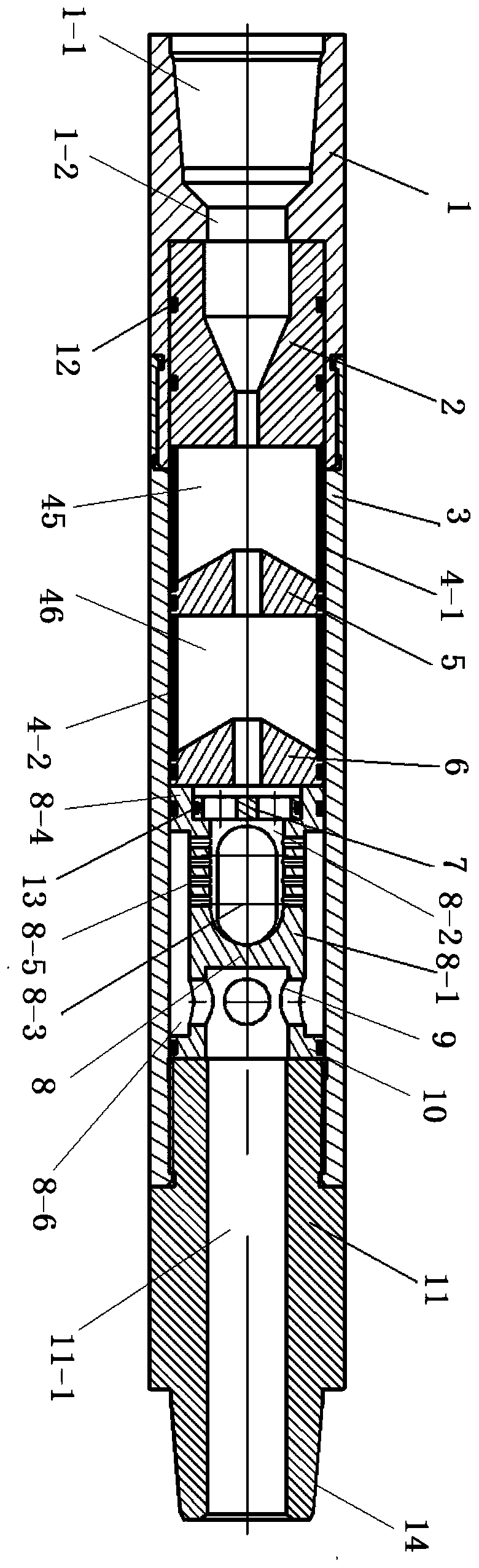

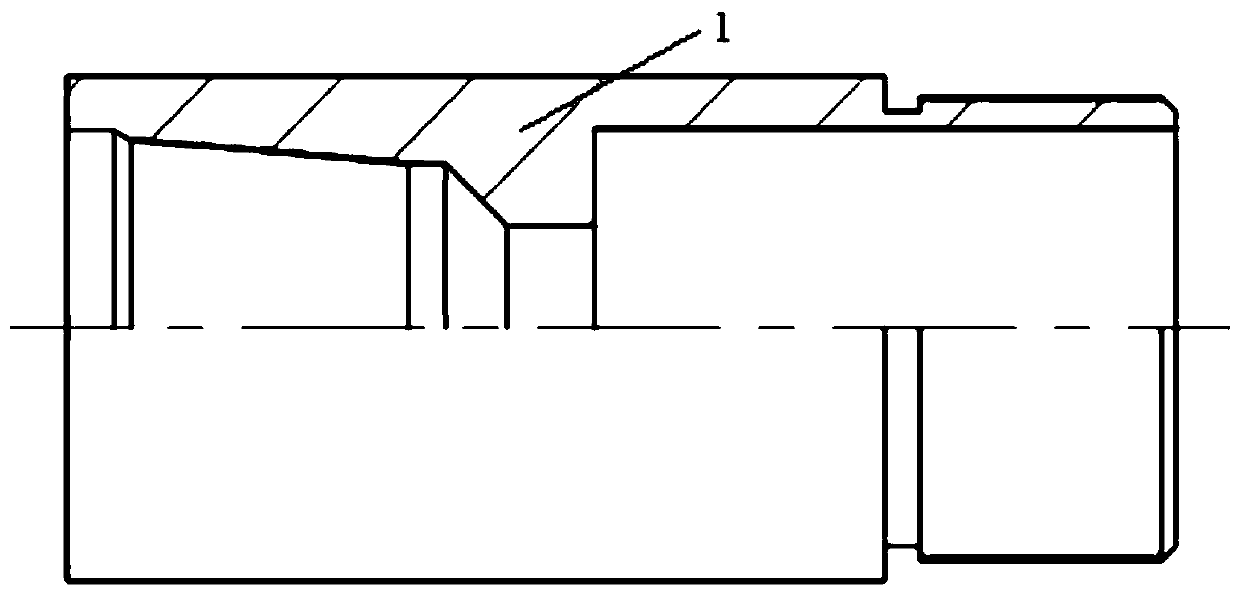

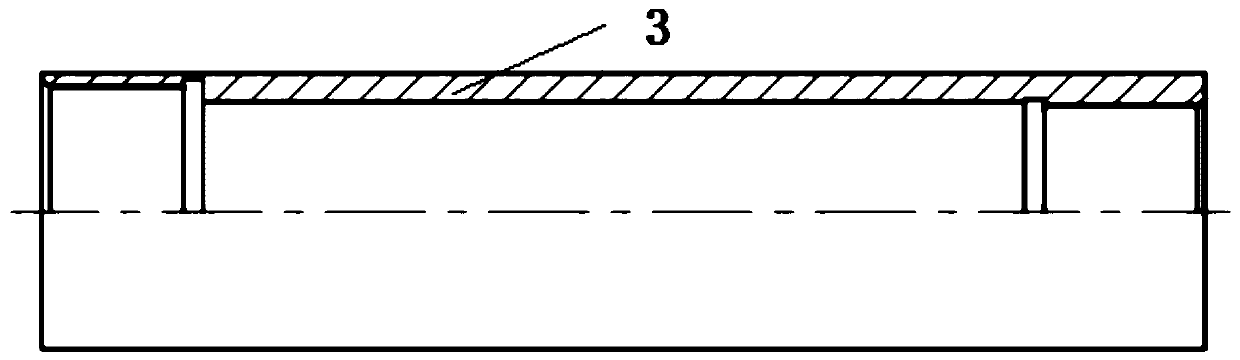

[0041] In this example, if Figure 1-12 As shown, a shimmy drilling tool for downhole friction and torsion reduction includes an upper joint 1, a threaded box 1-1 matching the drill pipe is arranged on the upper part of the upper joint 1, and the threaded box 1-1 is arranged below The liquid inlet channel 1-2 communicated with it in the axial direction, the lower end of the upper joint 1 is threadedly connected with the cylinder body 3, and a connected cavity is formed inside, and the upper nozzle 2, the upper nozzle 2, and the Upper positioning sleeve 4-1, middle nozzle 5, lower positioning sleeve 4-2, lower nozzle 6, splitter plate 7 and radial vibration nipple 8.

[0042] The upper end of the upper nozzle 2 is axially positioned by the inner step of the upper joint 1, and the lower end is axially positioned by the upper positioning sleeve 4-1, and the upper positioning sleeve 4-1 is positioned by the lower end of the upper nozzle 2 and the middle nozzle 5 respectively. The...

Embodiment 2

[0059] In this embodiment, the splitter plate 7 and the radial vibration nipple 8 are integrally formed, and the sealing and fixing method between the upper fixing step 8-4 and the inner wall of the cylinder body 3 is welding. As a fixing and sealing method, the above-mentioned welding method is adopted, so that the fixing is more stable and the sealing effect is good. Except above difference technical scheme, all the other technical schemes are identical with embodiment one.

[0060] The working principle of the present invention is as follows:

[0061] Connect the threaded box 1-1 of the upper joint 1 of the tool with the drill pipe, and the threaded pin 14 of the lower joint 11 with the drill pipe, run it downhole, and pressurize and circulate the drilling fluid for drilling:

[0062] First, the high-pressure drilling fluid enters the upper nozzle 2 from the liquid inlet channel 1-2 of the upper joint 1, and then passes through the first resonant cavity 45 and the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com