A three-dimensional vibration mode adjustable blade vibrator and its design method

A technology of three-dimensional vibration and vibration exciter, which is applied in vibration testing, testing of machine/structural components, measuring devices, etc., can solve problems such as low vibration frequency and single vibration mode, and achieve the effect of avoiding single excitation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose of the present invention, technical solutions and advantages clearer, the present invention will be further described in detail below in conjunction with examples. It should be noted that the following examples are only explanations of the present invention and the present invention is not limited to the following examples .

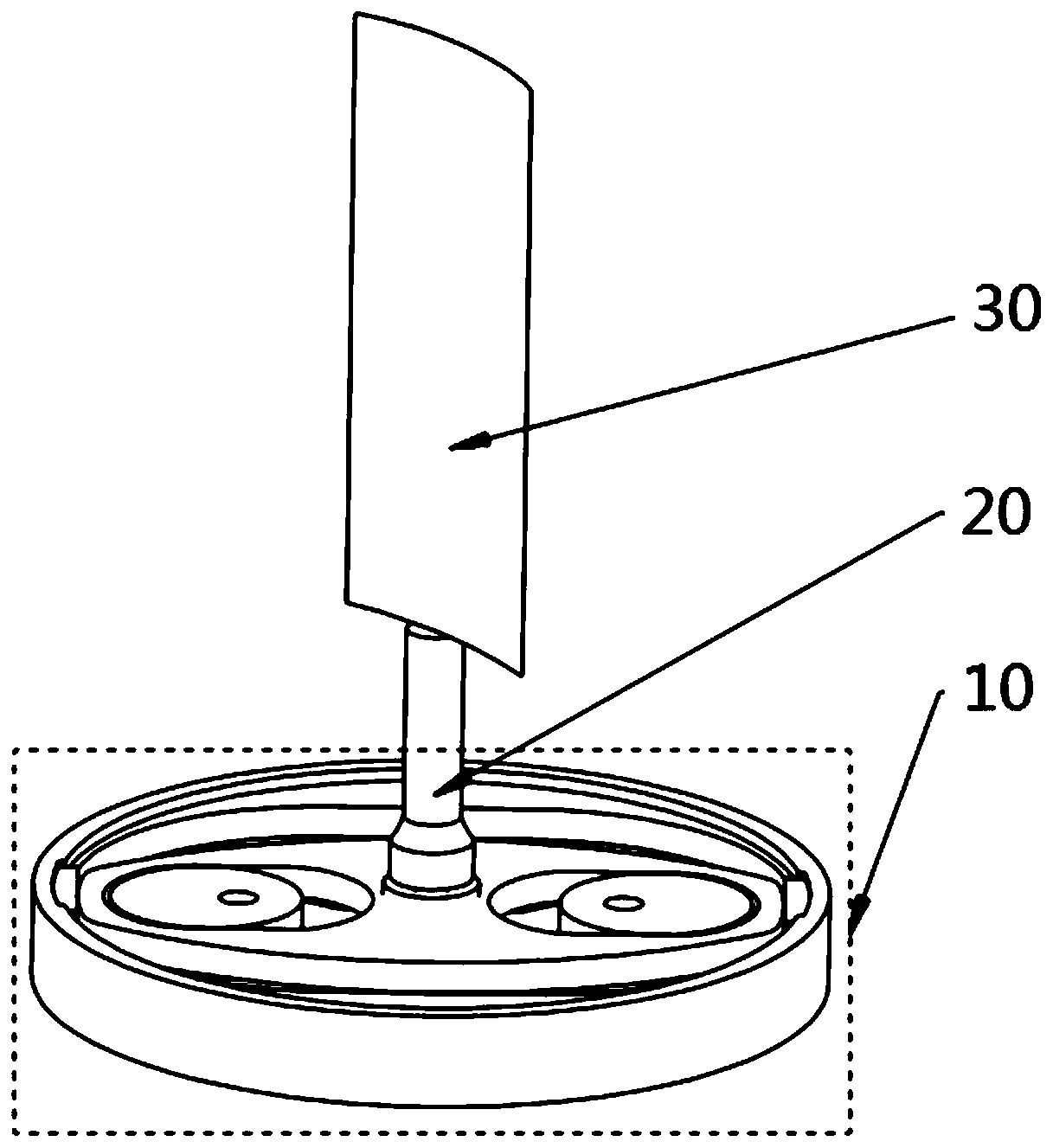

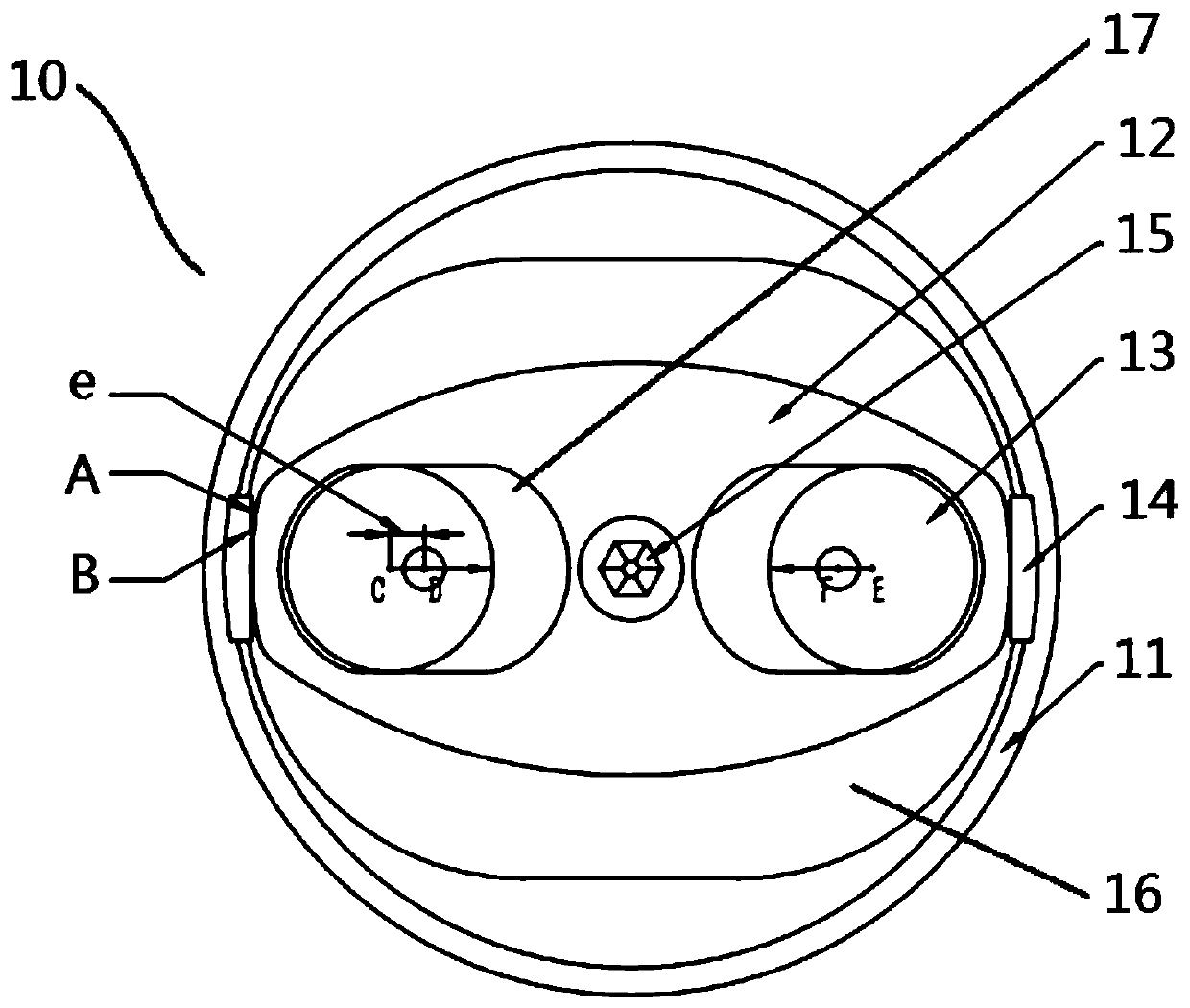

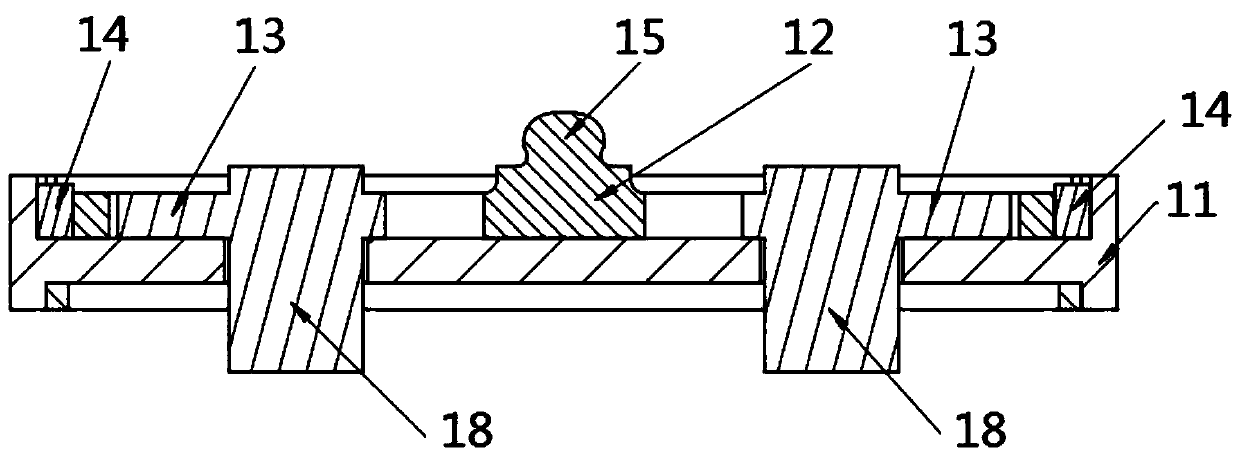

[0037] Such as figure 1 , 2, 3, and 4, the blade vibrator with adjustable three-dimensional vibration mode of the present invention includes a vibrator main body 10, a transmission column 20 and a blade 30, the end of the transmission column 20 is connected with the vibrator main body 10, and the transmission The top of the column 20 is fixedly connected with the blade root of the blade 30 . The exciter main body 10 includes a disc-shaped housing 11, a vibrating disc 12, a power eccentric wheel 13, a rail pin 14, and a ball joint base 15. The top of the disc-shaped housing 11 is provided with a strip-shaped cavity 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com