Cotton spinning machine

A cotton spinning machine and false twister technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve problems such as lowering work efficiency, affecting the normal operation of other equipment, affecting the health of personnel, etc. Achieve the effect of improving work efficiency, physical protection, and reducing impurity particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

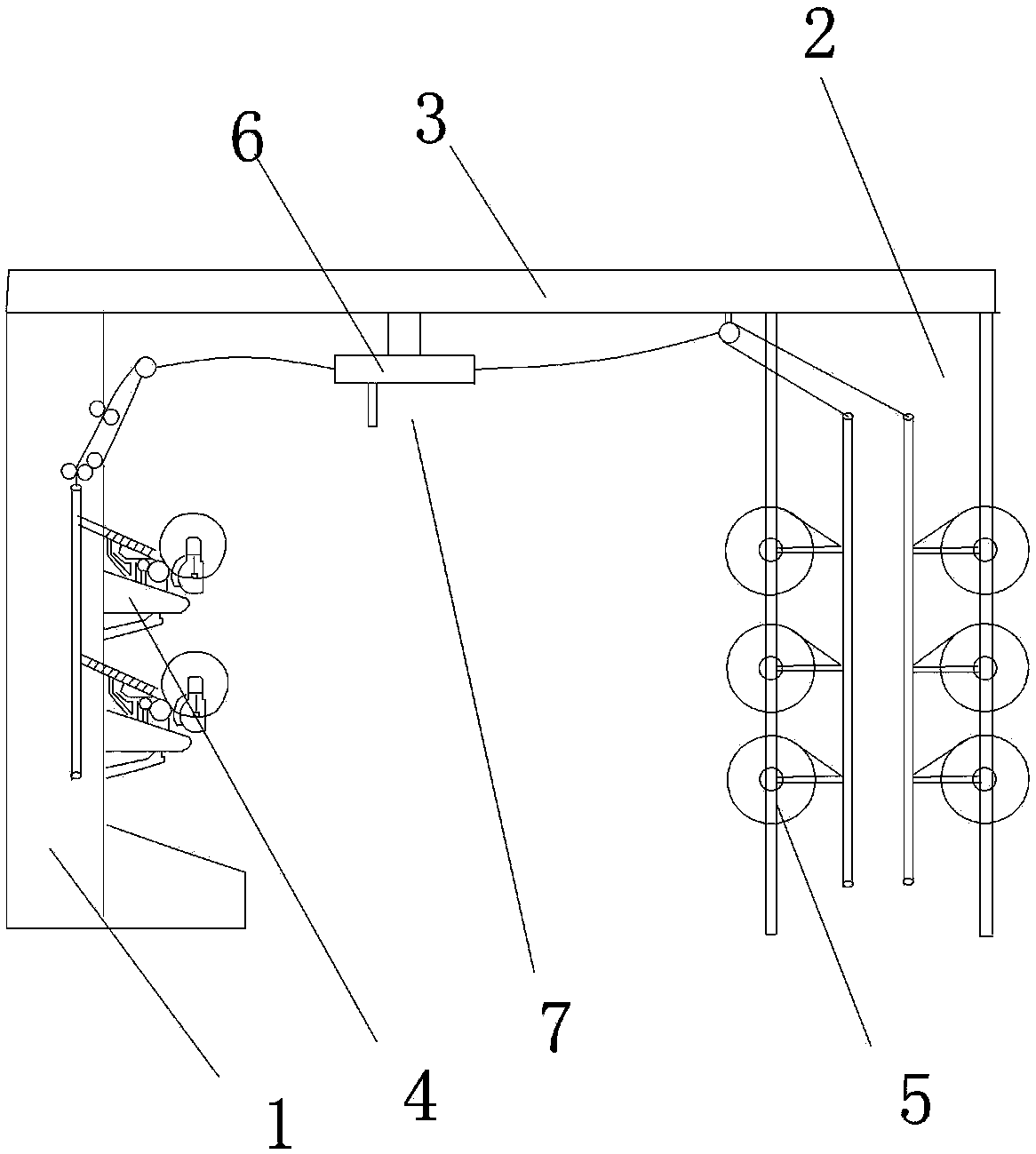

[0015] like figure 1 As shown, the present embodiment is a cotton spinning machine, including a left bracket 1, a right bracket 2 and a cross bar 3, the cross bar 3 is fixed to the top ends of the two brackets, and the left bracket 1 is provided with an oiling System 4, the right support 2 is provided with a yarn feeding system 5, and the oiling system 4 is connected with the yarn feeding system 5 by setting a false twister 6.

[0016] The false twister and the cross bar are fixedly connected by setting a metal block. On the one hand, the firmness of the false twister 6 can be strengthened; on the other hand, the false twister 6 can be made more stable when working, and Help to improve work efficiency.

[0017] In addition, the above-mentioned cotton spinning machine also includes a dust suction device 7, which is made of plastic ABS resin....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com