Composite material of hydrogenated nitrile rubber and polyurethane rubber and preparation method thereof

A technology of hydrogenated nitrile rubber and polyurethane rubber, which is applied in the field of rubber, can solve the problem of insoluble rubber materials, and achieve the effects of easy operation, superior wear resistance and good synergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the composite material of hydrogenated nitrile butadiene rubber and polyurethane rubber comprises the steps of: masticating and mixing polyurethane rubber and hydrogenated nitrile butadiene rubber until mixed rubber is obtained; wrapping the mixed rubber with rolls, adding carbon black and The plasticizer is mixed; then stearic acid, anti-aging agent, accelerator and vulcanizing agent are added in sequence and mixed; finally polyglycolic acid is added and mixed until the composite material of hydrogenated nitrile rubber and polyurethane rubber is obtained.

[0033] Plastication refers to the process of transforming rubber from a tough and highly elastic state to a soft plastic state by means of mechanical stress. After the rubber is deformed, it cannot return to its original state, or maintain the properties of its deformed state. The molecular weight of raw rubber is closely related to plasticity. The smaller the molecular weight, the greater...

Embodiment 1

[0036] The composite material of hydrogenated nitrile butadiene rubber of the present invention, polyurethane rubber comprises 65 parts of polyurethane rubbers, 35 parts of hydrogenated nitrile butadiene rubbers, 35 parts of carbon blacks, 1.5 parts of dioctyl dicarboxylates, 0.6 parts of stearic acid, methyl-2 - 0.7 parts of mercaptobenzimidazole, 0.7 parts of tetramethylthiuram disulfide, 3 parts of benzoyl peroxide and 25 parts of polyglycolic acid.

[0037] Preparation method: put polyurethane rubber and hydrogenated nitrile rubber on an open mill for mastication, and blend until uniform; adjust the roll distance of the open mill to make the rubber cover the roll, and gradually add carbon black and plasticizer; after completely mixing , add stearic acid, anti-aging agent, accelerator and vulcanizing agent in sequence; after being completely mixed, add polyglycolic acid and blend until uniform.

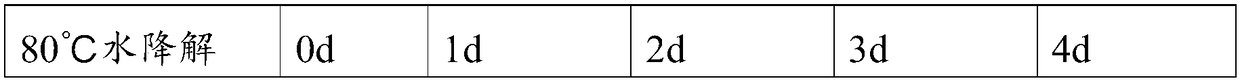

[0038] The performance parameter of the composite material of table 1 embodime...

Embodiment 2

[0042]The composite material of hydrogenated nitrile butadiene rubber and polyurethane rubber of the present invention comprises 60 parts of polyurethane rubber, 40 parts of hydrogenated nitrile butadiene rubber, 20 parts of carbon black, 2 parts of benzoyl peroxide, 0.2 part of stearic acid, octylated diphenylamine 1 part, 0.5 parts of 4,4'-dithiobimorpholine, 4 parts of N, N' m-phenylene maleimide and 10 parts of polyglycolic acid.

[0043] Preparation method is the same as embodiment 1

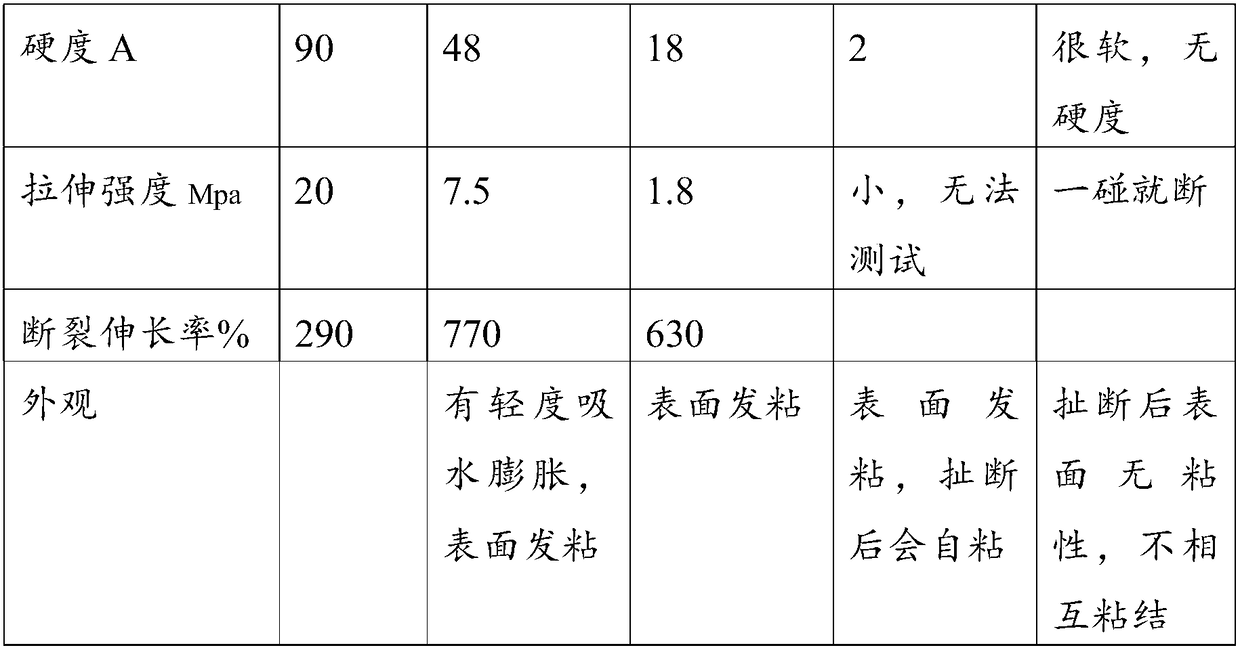

[0044] The performance parameter of the composite material of table 2 embodiment 2

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com