Automatic punching device for cylinder body water sleeve

A drilling device and cylinder water jacket technology, which is applied in casting molding equipment, metal processing, casting molds, etc., can solve the problems of increased cost of core making, short tool life, and more labor, so as to prolong life, improve quality, The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

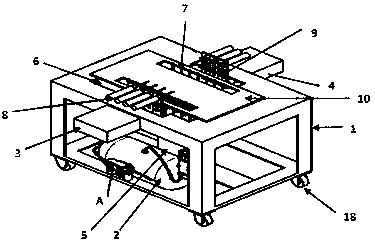

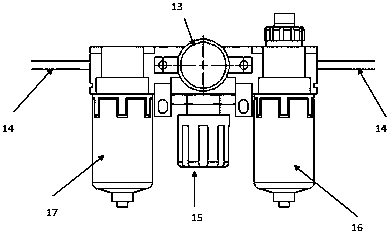

[0021] Such as figure 1 Shown: the present invention relates to an automatic punching device for a water jacket of a cylinder body, comprising a steel structure support 1, an air storage tank 2, a first cylinder 3, a second cylinder 4, a third cylinder 5, a universal wheel 18, an operating electric The cabinet 11 and the PLC program controller 12, the steel structure support 1 includes an upper platform and a lower platform, the gas storage tank 2 is arranged on the lower platform, a groove 6 is formed in the middle of the upper platform, and a positioning fixture 10 is arranged at the position of the groove 6 A first side air drill 8 and a second side air drill 9 are respectively arranged on both sides of the positioning jig 10 for driving the first cylinder 3 and the second cylinder of the first side air drill 8 and the second side air drill 9 4 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com