Disassembly tool for bowl-shaped plug

A technology for dismantling tools and bowl-shaped plugs, which is applied in the manufacture of tools and hand-held tools, can solve the problems of long time consumption, high labor intensity, and low work efficiency, and achieve maintenance efficiency improvement, labor intensity reduction, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0024] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

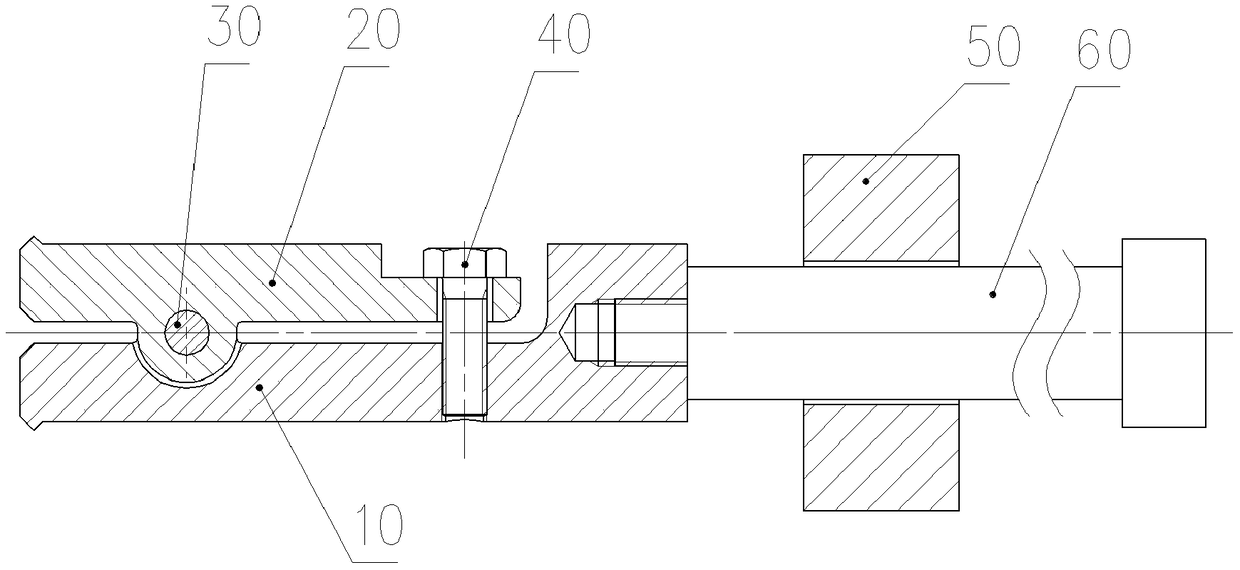

[0025] Such as figure 1 As shown, the dismantling tool for a bowl plug according to the preferred embodiment of the present invention includes: a lower clamping seat 10 , an upper clamping base 20 , a pin shaft 30 , a locking bolt 40 , a sliding hammer 50 and a sliding rod 60 .

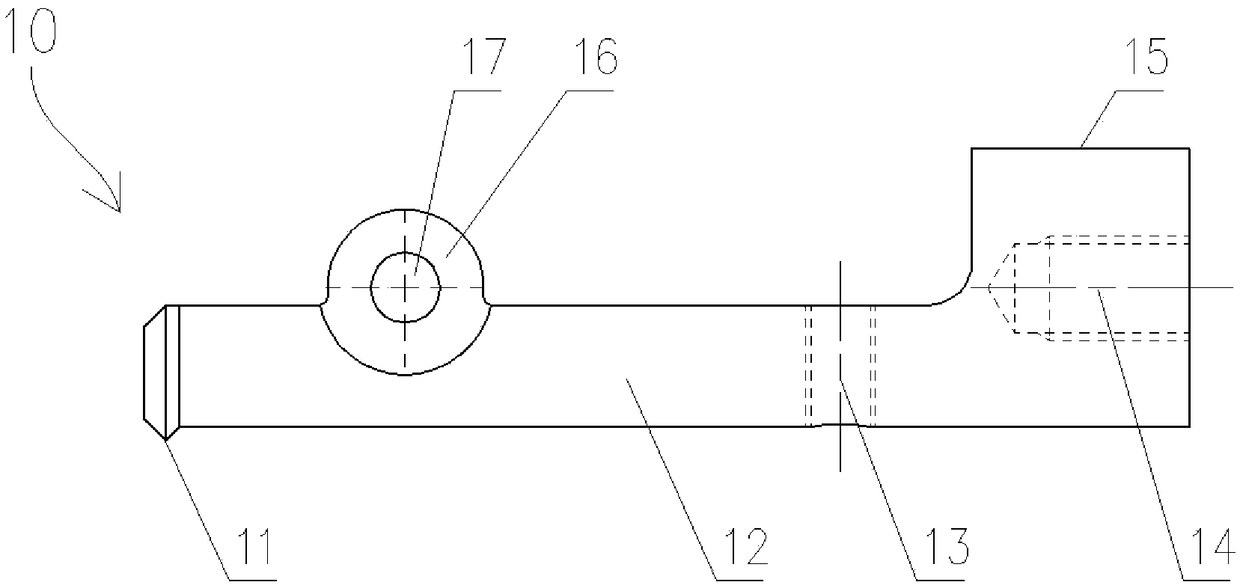

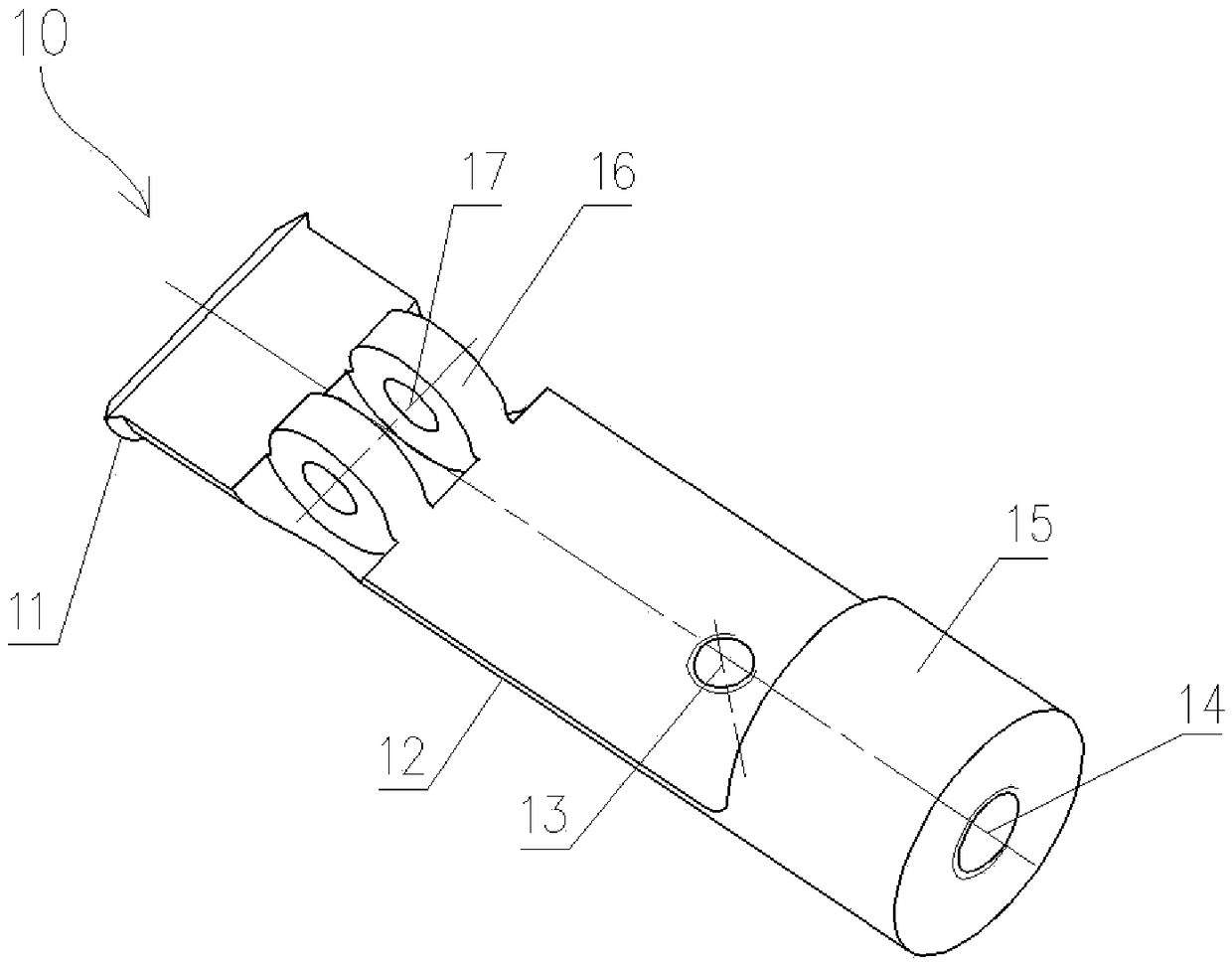

[0026] Such as figure 2 , image 3 As shown, the main structure of the lower deck 10 is the lower deck semicircle 12, and the lower deck semic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com