Automatic material receiving device for machine tool materials

A material receiving device and material technology, applied in the field of machine tools, can solve the problems affecting material receiving, height error, not in the middle of disc materials, etc., to ensure smoothness, fast sliding speed, and increase kinetic energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

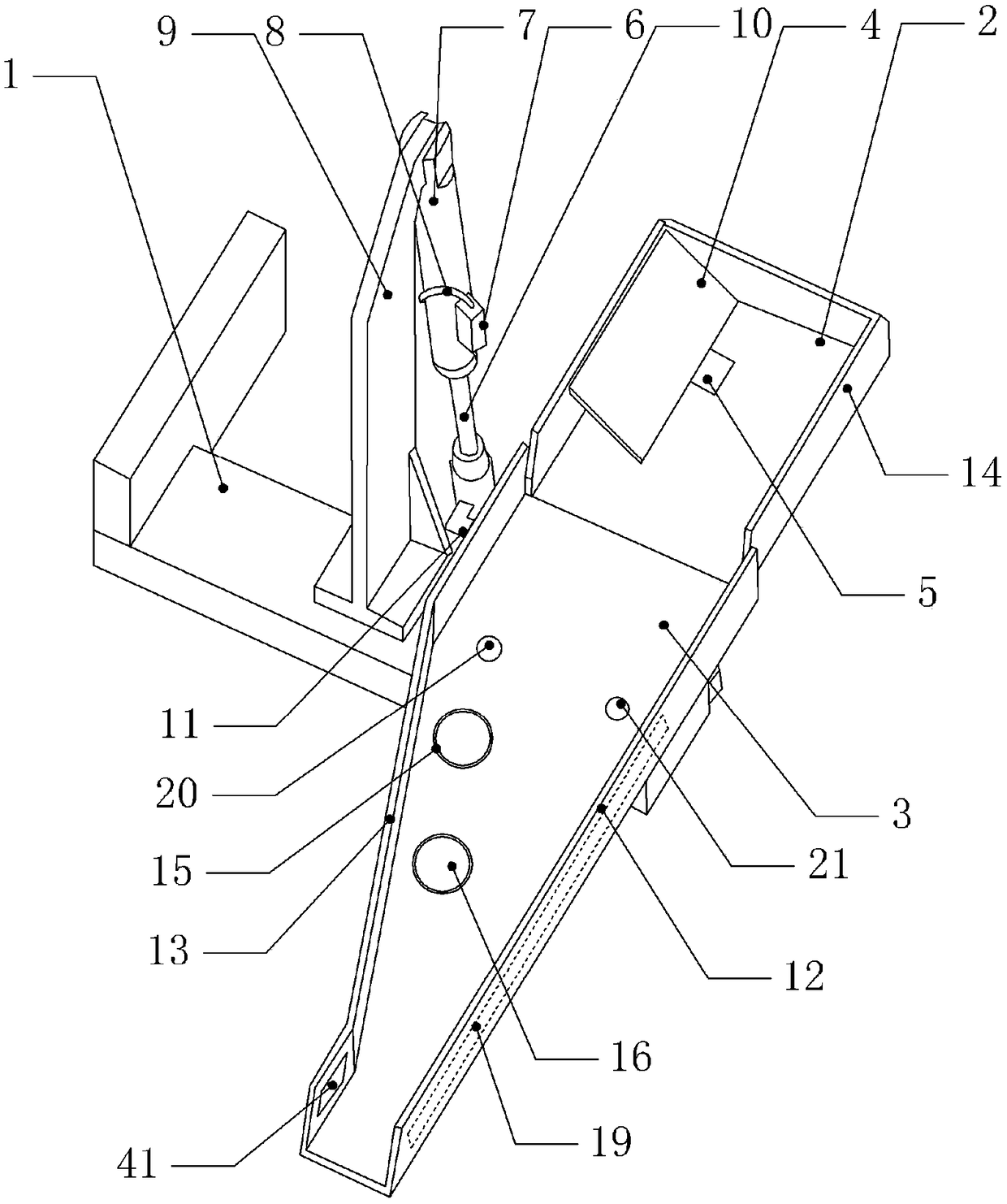

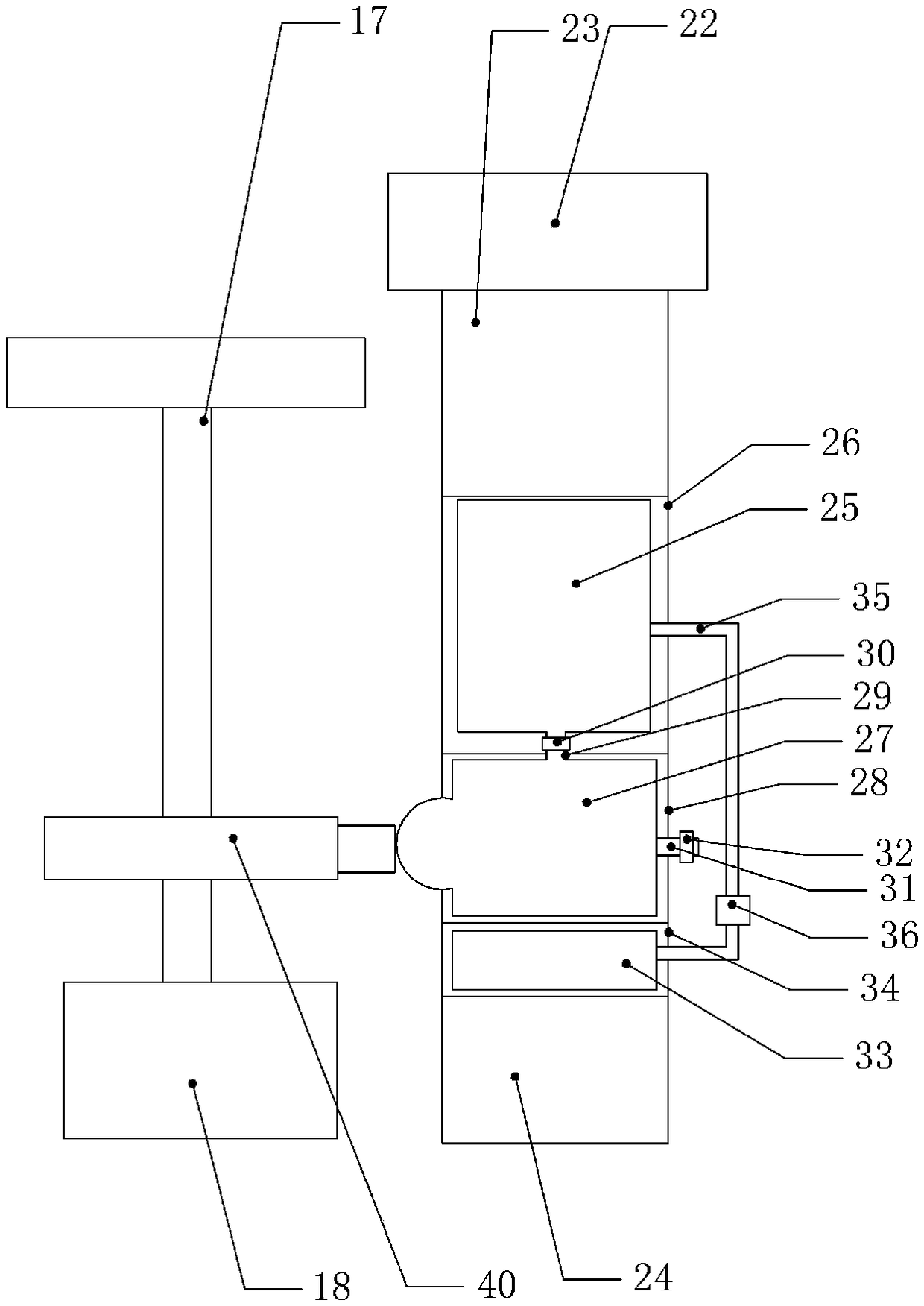

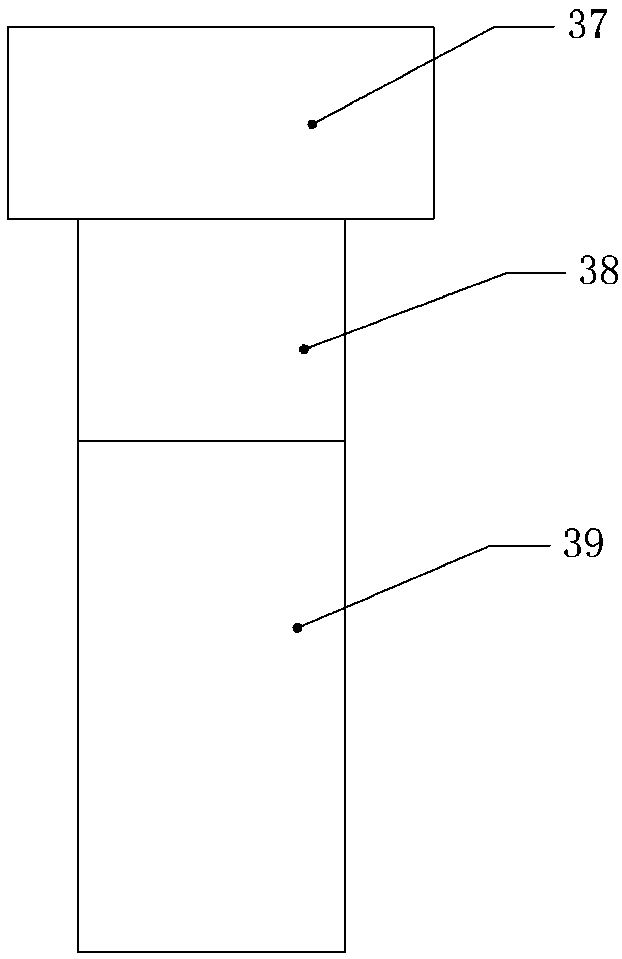

[0027] Such as figure 1 , figure 2 and image 3 Shown: The automatic feeding device for machine tool materials, including a fixed frame 1, a rotary feeding tray 2 and a fixed feeding tray 3, the fixed feeding tray 3 is set obliquely downward, and the fixed feeding tray 3 is connected to the fixed frame 1, The high end of the fixed receiving tray 3 is hinged with the rotary receiving tray 2, and the lower end of the fixed receiving tray 3 is provided with a discharge port. There is a drive mechanism on the fixed frame 1, and a guide plate 4 is provided on the left side of the revolving tray 2, and the guide plate 4 is set obliquely downward, and a pressure sensor is arranged on the side of the revolving tray 2 close to the guide plate 4 5 and the controller. The drive mechanism includes an air pump 6 and a push cylinder 7, the air pump 6 is connected with the push cylinder 7 through a first air pipe 8, the air pump 6 is welded on the push cylinder 7, the fixed frame 1 is co...

Embodiment 2

[0033] Such as Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the back side of the rotary receiving tray 2 is connected with a connecting plate 42 by bolts, and the side of the fixed frame 1 close to the rotary receiving tray 2 is connected with a rotary shaft 43 in rotation. , the connecting plate 42 is connected with the rotary shaft 43 by the U-shaped block 44, and the side bolt of the U-shaped block 44 near the push cylinder 7 is connected with a projection 45, and the projection 45 is hinged with the lower end of the piston rod 10. By setting the rotary shaft 43 on the fixed frame 1, and then connecting the rotary receiving tray 2 through the U-shaped block 44, the turning point of the rotary receiving tray 2 is based on the rotary shaft 43 on the fixed frame 1. , so that the turning of the rotary receiving tray 2 is more stable without shaking, and the material receiving and transferring process is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com