Welding aids

A technology of auxiliary equipment and welding tongs, which is applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve the problems of increased welding cost, narrow welding operation space, and low welding efficiency, and achieves convenient welding, large welding operation space, The effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

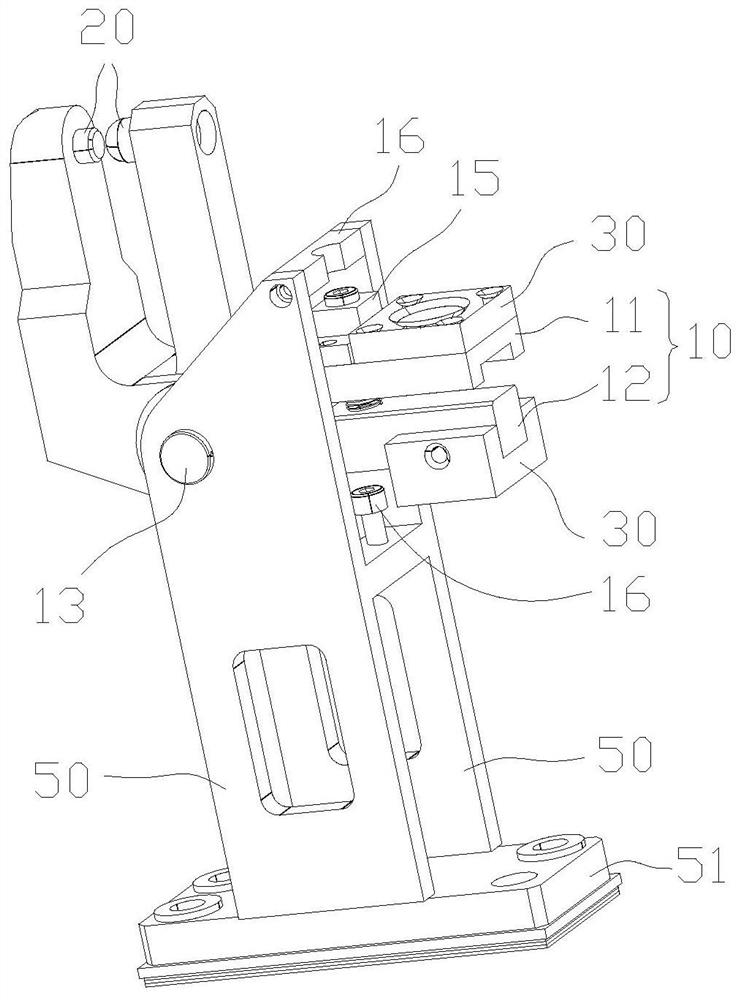

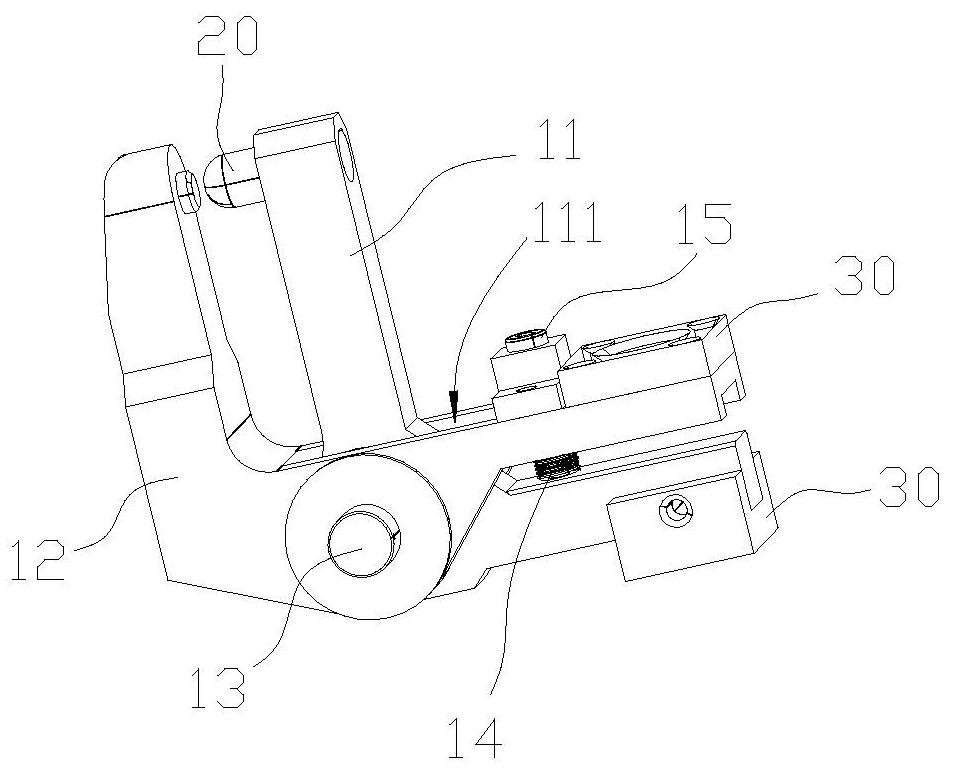

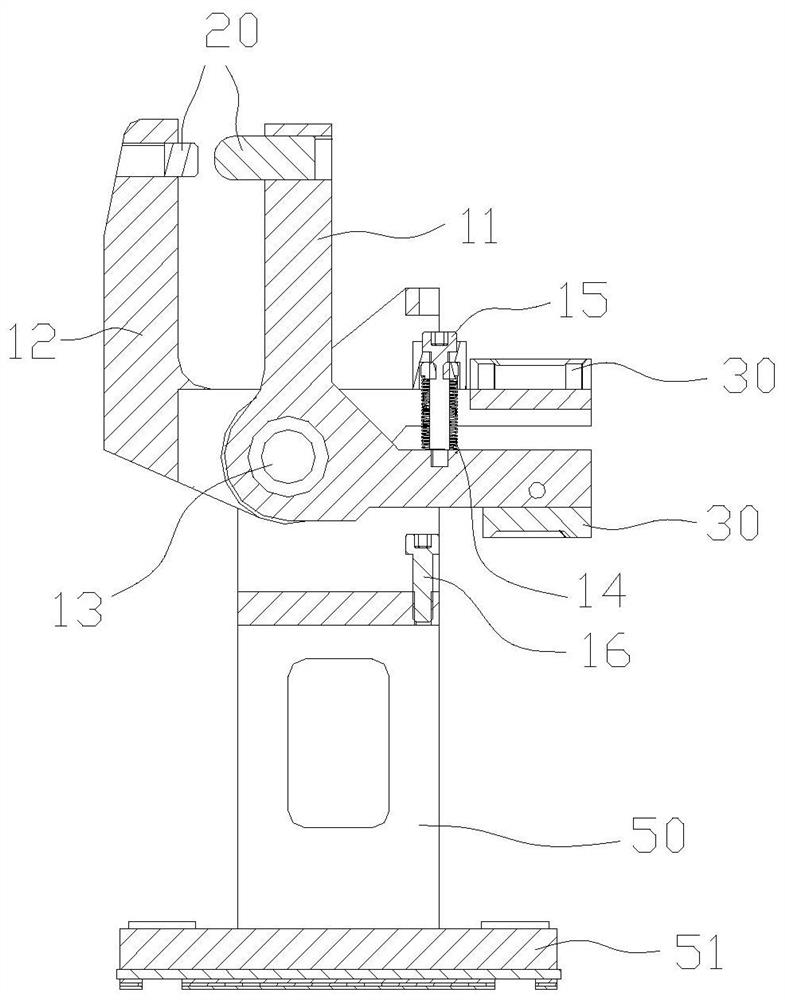

[0013] A welding aid, the top cover 6 to be welded is placed flat on the workbench, one end of the welding tongs arm 10 is arranged with an electrode cap 20, and the other end is connected to an electrode plate 30, and the electrode caps at one end of the two welding tongs arms 10 are 20 points apart. It is placed on both sides of the two plates to be welded and opened and closed in the horizontal direction. The electrode plate 30 at the other end of the two welding tongs arms 10 is located in the window of the skylight 1, and the middle parts of the two welding tongs arms 10 are hinged on the bracket plate 50. The welding tongs 2 open and close in the vertical direction to drive the two electrode plates 30 and drive the electrode caps 20 to approach each other and horizontally clamp the parts to be welded on the two plates.

[0014] In the above scheme, the ordinary welding tongs 2 perform open and close welding actions in the vertical direction, while the window flange 4 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com